pre cut galvanized tie wire factory

Pre-Cut Galvanized Tie Wire A Comprehensive Overview of Its Manufacturing and Applications

Tie wire, often overlooked in the construction and manufacturing industries, plays a critical role in a wide variety of applications. Among the different types of tie wire available, pre-cut galvanized tie wire has emerged as a preferred choice for many professionals due to its durability and ease of use. This article delves into the significance, manufacturing process, and various applications of pre-cut galvanized tie wire, providing an in-depth overview for industry stakeholders.

Understanding Pre-Cut Galvanized Tie Wire

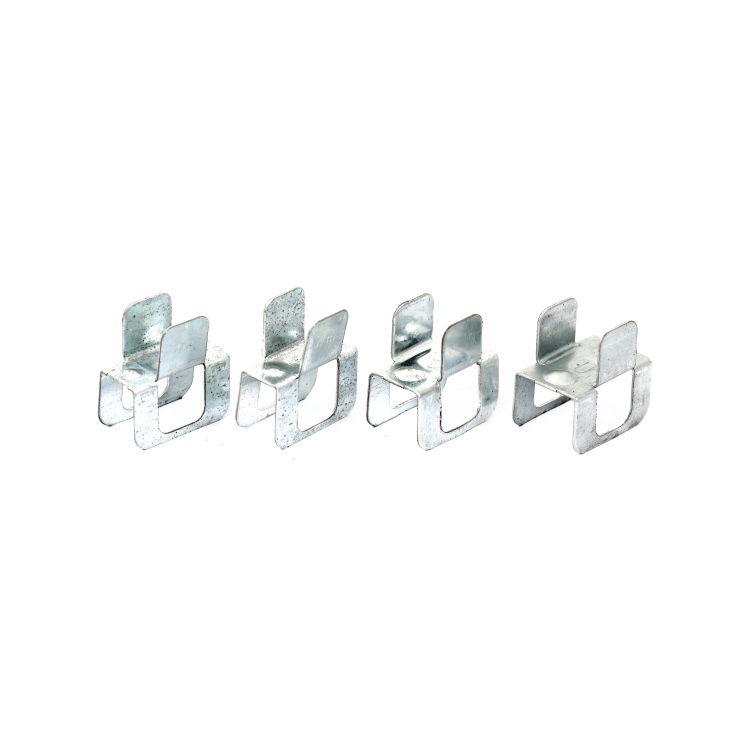

Pre-cut galvanized tie wire is a type of wire that has undergone a galvanization process, where it is coated with zinc to enhance its resistance to corrosion. This property is particularly beneficial in outdoor and high-moisture environments, making it suitable for construction sites, gardening, and fencing. The pre-cut aspect means that the wire is cut to specific lengths prior to being sold, allowing for greater convenience and efficiency during installation.

Manufacturing Process

The manufacturing of pre-cut galvanized tie wire involves several steps. First, the wire is produced from high-quality steel, which is then drawn through a series of dies to achieve the desired thickness. Once the wire reaches the appropriate diameter, it is subjected to the galvanization process, where it is coated with molten zinc. This step not only provides protective qualities but also enhances the wire's tensile strength, ensuring it can withstand significant pressure without breaking.

After galvanization, the wire is cooled and then cut into predetermined lengths, ranging from short strands suitable for tying small bundles to longer lengths for larger projects. The pre-cut feature eliminates the need for workers to measure and cut wire on-site, saving time and reducing waste.

Benefits of Using Pre-Cut Galvanized Tie Wire

1. Durability The zinc coating on galvanized tie wire significantly extends its lifespan, even in challenging environmental conditions. This durability reduces the frequency of replacements, ultimately saving costs over time.

2. Convenience Being pre-cut means that users can instantly use the wire without any additional preparation. This convenience is essential on busy job sites where efficiency is crucial.

pre cut galvanized tie wire factory

3. Versatility Pre-cut galvanized tie wire can be used in a multitude of applications, from securing rebar in concrete to bundling plants and trees in landscaping projects. Its flexibility and strength provide solutions across various sectors.

4. Cost-Effectiveness While the initial investment in galvanized tie wire may be slightly higher than regular wire, the long-term savings due to its durability and reduced maintenance needs can make it a more economical option.

Applications of Pre-Cut Galvanized Tie Wire

Pre-cut galvanized tie wire is widely used in numerous sectors

1. Construction In construction, it is primarily used for tying rebar and securing various components of concrete structures, ensuring stability and structural integrity.

2. Gardening and Landscaping Gardeners frequently use tie wire for plant support, such as staking plants or securing climbing vines. Its resistance to rust ensures that its strength is maintained over time.

3. Fencing When constructing fences, pre-cut galvanized tie wire is used to attach fencing materials effectively, providing reliable reinforcement.

4. General Manufacturing In industries requiring bundling or securing materials, pre-cut tie wire serves as an efficient solution due to its strength and versatility.

Conclusion

Pre-cut galvanized tie wire is an essential component in various industries, offering durability, convenience, and versatility. Its manufacturing process ensures that users receive a high-quality product specifically designed for robust applications. As professionals continue to seek efficient solutions to meet their construction, gardening, and manufacturing needs, the demand for pre-cut galvanized tie wire is likely to remain strong. Investing in this material not only enhances project outcomes but also contributes to cost efficiency and sustainability in operations. Whether in construction or landscaping, pre-cut galvanized tie wire proves to be an indispensable tool that aids in achieving the desired results efficiently.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025