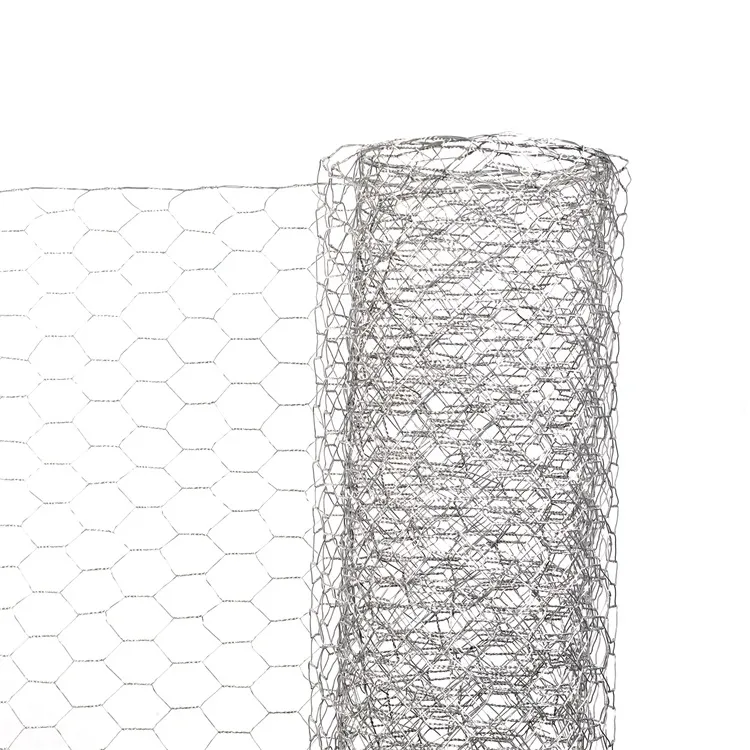

Durable Hexagonal Wire Netting For Modern Applications

Hexagonal wire netting, also known as hexagonal wire mesh or chicken wire PVC, is a highly versatile material with wide-ranging applications in agriculture, construction, and industrial settings. Its unique six-sided honeycomb pattern provides exceptional flexibility and strength, making it ideal for various fencing and enclosure needs. Hebei Leeter Import and Export Co., Ltd specializes in manufacturing high-quality hexagonal wire netting products that meet international standards, offering durable and cost-effective solutions for bulk purchasers worldwide.

Structural Advantages of Hexagonal Wire Netting

The honeycomb configuration of hexagonal wire netting naturally distributes stress across multiple connection points, allowing the mesh to absorb impacts and withstand pressure that would deform other wire patterns. This unique design provides remarkable flexibility, enabling the material to conform to uneven terrain while maintaining its structural integrity. The chicken wire PVC variant offers additional benefits with its protective plastic coating that resists corrosion, UV radiation, and chemical exposure. Unlike traditional galvanized options, PVC-coated mesh maintains its appearance and functionality even in coastal regions with high salt content in the air, making it ideal for long-term outdoor applications where durability is paramount.

Hexagonal Wire Mesh Diverse Applications Across Industries

In agricultural settings, hexagonal wire mesh serves as the preferred choice for poultry enclosures, providing secure containment while allowing adequate ventilation crucial for animal health. Construction professionals utilize it for gabion baskets and slope stabilization projects, where its ability to hold rocks and soil makes it perfect for erosion control. The industrial sector employs hexagonal wire netting for machine guarding and filtration systems, taking advantage of its consistent openings for reliable particle separation. Landscapers favor chicken wire PVC for decorative applications like plant supports and trellises, where its rust-proof qualities and color options blend seamlessly with garden environments while maintaining structural integrity over time.

E Hexagonal Wire Netting Material Selection Considerations

Selecting the appropriate hexagonal wire netting requires careful evaluation of several technical specifications. Wire gauge thickness directly impacts the mesh's strength, with lower gauge numbers indicating thicker, more durable wire suitable for security applications. Mesh opening size varies from 1/2" for small animal protection to 2" or more for poultry runs requiring better visibility and airflow. For chicken wire PVC, the coating quality is critical - premium products feature thick, uniform PVC layers that completely encapsulate the base wire, while inferior options may have thin or uneven coatings that compromise durability. Hebei Leeter offers comprehensive customization options, allowing clients to specify exact combinations of wire gauge, mesh size, and PVC coating characteristics to match their specific project requirements.

Hexagonal Wire Mesh Installation Techniques and Best Practices

Proper installation begins with preparing the area by removing debris and obstacles that might interfere with the mesh. For fencing applications, professionals recommend setting sturdy posts at 6-8 foot intervals to provide adequate support. When unrolling hexagonal wire mesh, care must be taken to avoid kinks or twists that could weaken the material. Using appropriate tensioning tools ensures the mesh stretches taut between posts, eliminating sagging that might compromise security. In soil reinforcement projects, proper overlap (minimum 6 inches) between adjacent hexagonal wire netting sheets is essential, secured with sturdy wire ties or specialized connectors. For chicken wire PVC installations, PVC-coated ties or stainless steel fasteners prevent corrosion at connection points, while avoiding sharp bends protects the integrity of the plastic coating.

FAQS about Hexagonal Wire Netting

What are the primary differences between galvanized and chicken wire PVC-coated hexagonal wire mesh?

Galvanized hexagonal wire mesh features a zinc coating that provides basic corrosion resistance, making it suitable for general-purpose applications.chicken wire PVC, on the other hand, has an additional layer of plastic coating that offers superior protection against harsh weather conditions, UV rays, and chemical exposure. While both types are durable, PVC-coated mesh typically lasts longer in coastal or high-moisture environments and is available in various colors for aesthetic purposes.

How does the wire gauge affect the performance of hexagonal wire netting?

The wire gauge directly determines the strength and durability of hexagonal wire netting. Thicker wires (lower gauge numbers) create a more rigid and durable mesh suitable for security fencing and animal enclosures, while thinner wires (higher gauge numbers) offer greater flexibility for decorative applications or temporary fencing. Hebei Leeter provides detailed technical specifications to help customers select the appropriate gauge for their specific needs.

Can hexagonal wire mesh be used for aquaculture applications?

Yes, hexagonal wire mesh is commonly used in aquaculture for constructing cages and enclosures. The PVC-coated version (chicken wire PVC) is particularly suitable as it resists corrosion from constant water exposure. The mesh openings can be customized to contain specific fish sizes while allowing proper water circulation. However, saltwater applications may require special anti-corrosion treatments beyond standard PVC coating.

How does temperature affect the installation of chicken wire PVC?

Extreme temperatures can impact chicken wire PVC installation. In cold weather, the PVC coating becomes less flexible, making the mesh harder to unroll and shape - warming the material before installation helps. In hot climates, the mesh may expand slightly, so installers should allow minimal slack to prevent over-tensioning as temperatures drop. The ideal installation temperature range is typically between 50°F and 85°F (10°C to 30°C).

What safety precautions should be taken when working with hexagonal wire mesh?

Always wear heavy-duty gloves when handling hexagonal wire netting as the cut ends can be sharp, even on PVC-coated versions. Use appropriate eye protection when cutting the mesh, and consider wearing long sleeves to prevent scratches. When installing at heights or on slopes, proper fall protection equipment should be used. For large projects, two-person handling is recommended to prevent strain injuries from the weight of the rolls.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025