oem automatic tools

The Importance of OEM Automatic Tools in Modern Manufacturing

In today’s fast-paced manufacturing landscape, the demand for efficiency and precision has never been higher. Original Equipment Manufacturer (OEM) automatic tools play a pivotal role in this environment, enabling businesses to streamline processes, reduce costs, and enhance product quality. Understanding the importance of these tools can provide insights into how they can significantly impact production operations.

What are OEM Automatic Tools?

OEM automatic tools are specialized machinery and equipment designed and produced by manufacturers to meet specific needs of other companies. Unlike generic tools, OEM products often come with unique features or specifications tailored to the particular requirements of the end user. These tools can include automatic lathes, CNC machines, robotic arms, and other machinery that enhances automation in manufacturing processes.

Enhancing Efficiency

One of the key advantages of using OEM automatic tools is the enhancement of operational efficiency. Automated tools can perform repetitive tasks with high precision and speed, significantly reducing the time taken for production. For example, a fully automated CNC milling machine can produce components at a considerably faster rate compared to manual machining processes. By minimizing human intervention, these tools also reduce the possibility of errors, leading to more consistent output quality.

Cost Reduction

Implementing OEM automatic tools can lead to substantial cost savings over time. While the initial investment may be higher than that of traditional tools, the long-term benefits often outweigh these costs. Automation reduces labor costs by minimizing the number of workers needed for production. Additionally, the precision of OEM tools means reduced material waste, as components are manufactured closer to specification, resulting in fewer defective products.

oem automatic tools

Improved Product Quality

Quality control is a vital aspect of manufacturing, as it directly influences customer satisfaction and brand reputation. OEM automatic tools enhance product quality by ensuring that every component is produced to the same exacting standards. Automated systems can monitor production in real-time, adjusting parameters as needed to maintain quality. This consistency leads to a reduction in rework and scrap rates, further solidifying the manufacturer’s reputation for reliability and excellence.

Flexibility and Scalability

Another significant advantage of OEM automatic tools is their flexibility and scalability. As market demands change, manufacturers need to adapt quickly. Advanced automatic tools can be reprogrammed or adjusted to accommodate different production runs without the need for significant downtime or retooling. This capability enables manufacturers to respond effectively to fluctuating consumer demands, making them more competitive in the marketplace.

Integration with Technology

In recent years, the integration of Industry 4.0 technologies such as the Internet of Things (IoT) and artificial intelligence (AI) with OEM automatic tools has revolutionized manufacturing. Smart machinery can collect data on production processes, allowing for predictive maintenance and minimizing downtime. The ability to analyze data in real-time means manufacturers can make informed decisions quickly, optimizing production further.

Conclusion

With the ongoing advancements in manufacturing technologies, OEM automatic tools are more crucial than ever. They not only streamline production processes and improve efficiency but also contribute to significant cost savings, enhanced product quality, and greater flexibility in meeting market demands. As businesses continue to navigate the challenges of modern manufacturing, investing in OEM automatic tools will likely remain a strategic move, ensuring competitiveness and success in an ever-evolving landscape. In essence, these tools are not just assets; they are vital components that drive the future of manufacturing forward.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

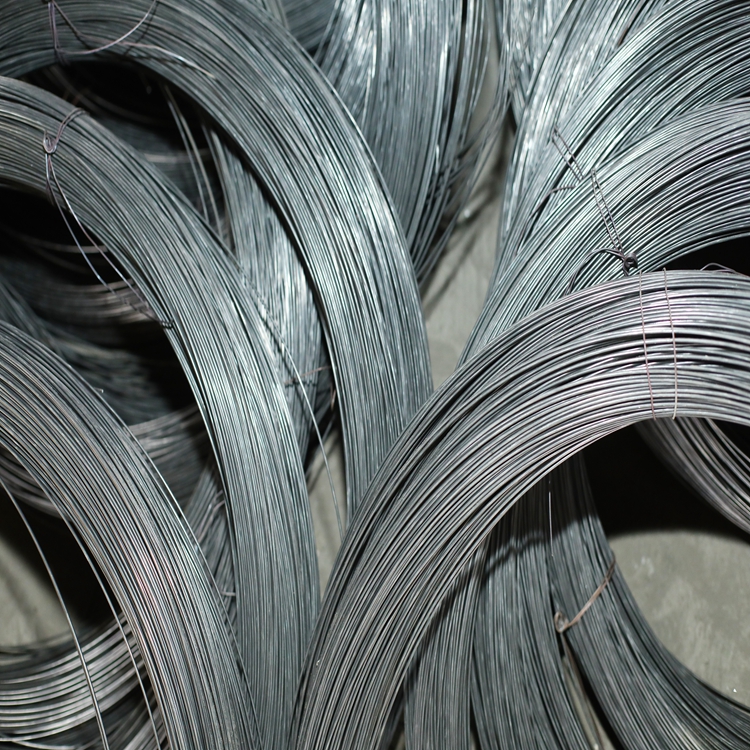

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025