Nails Used by Exporters of Epoxy Pallets for Improved Durability and Strength

Nails for Epoxy Pallet Exporters Ensuring Quality and Reliability in the Global Market

In the world of logistics and shipping, one of the unsung heroes is the humble pallet. Epoxy pallets, which are made from durable and weather-resistant materials, have become increasingly popular due to their versatility and longevity. However, the effectiveness of these pallets relies not only on their material composition but also on the quality of nails used in their construction. For exporters specializing in epoxy pallets, understanding the significance of nails is crucial for ensuring the integrity of their products in the global market.

Epoxy pallets are designed to withstand various environmental conditions, making them ideal for international shipping. They are resistant to moisture, chemicals, and extreme temperatures, which means they can be reused multiple times without compromising their structural integrity. However, the longevity and strength of these pallets depend heavily on the nails that hold them together. Quality nails ensure that the pallets remain intact even under heavy loads and during long journeys, which reduces the risk of damage to goods being transported.

Nails for Epoxy Pallet Exporters Ensuring Quality and Reliability in the Global Market

In terms of coatings, exporters should opt for nails that have a protective finish to enhance their durability. This aspect is particularly critical when exporting to regions with harsh climates, as uncoated nails may rust or deteriorate quickly, leading to potential failure of the pallets. Therefore, it is essential for exporters to partner with reliable nail manufacturers who can provide high-quality products that meet international standards.

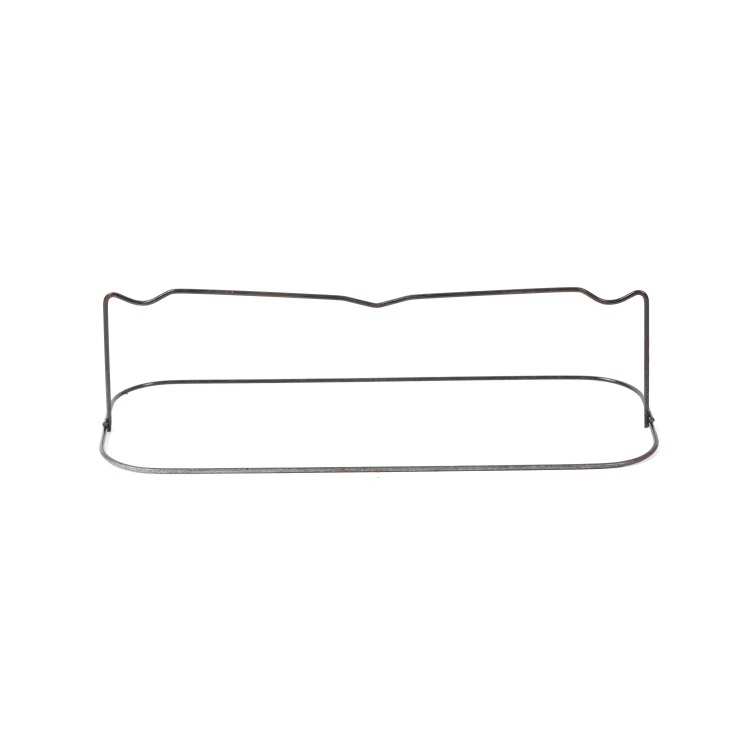

nails for epal pallets exporters

Quality control processes are vital in the production of nails for epoxy pallets. Exporters must ensure that the nails undergo rigorous testing for strength and resilience. This is essential not only for safeguarding the pallets but also for maintaining the reputation of the exporting company. Businesses need to establish a supply chain that prioritizes quality, sourcing nails only from manufacturers with a proven track record and industry certifications.

Furthermore, understanding market demands and industry trends can help exporters stay competitive. As more businesses recognize the benefits of epoxy pallets in minimizing shipping costs and reducing waste, the demand for high-quality nails will only increase. Exporters should be proactive in researching market needs and adapting their products accordingly.

Sustainability is another growing concern in the global shipping industry. Many companies are seeking eco-friendly materials and practices, which applies to the nails used in epoxy pallets as well. By selecting nails manufactured from recycled materials or adopting environmentally friendly production methods, exporters can position themselves as leaders in sustainable practices, appealing to environmentally conscious clients.

In conclusion, the role of nails in the construction of epoxy pallets is a key consideration for suppliers in the export market. As the global demand for durable and efficient shipping solutions continues to rise, ensuring the quality and reliability of nails will play a vital part in the success of epoxy pallet exporters. By prioritizing quality, understanding market trends, and embracing sustainability, these businesses can build lasting partnerships and thrive in an increasingly competitive marketplace.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025