hot galvanized common nails supplier

Exploring the World of Hot Galvanized Common Nails A Supplier's Perspective

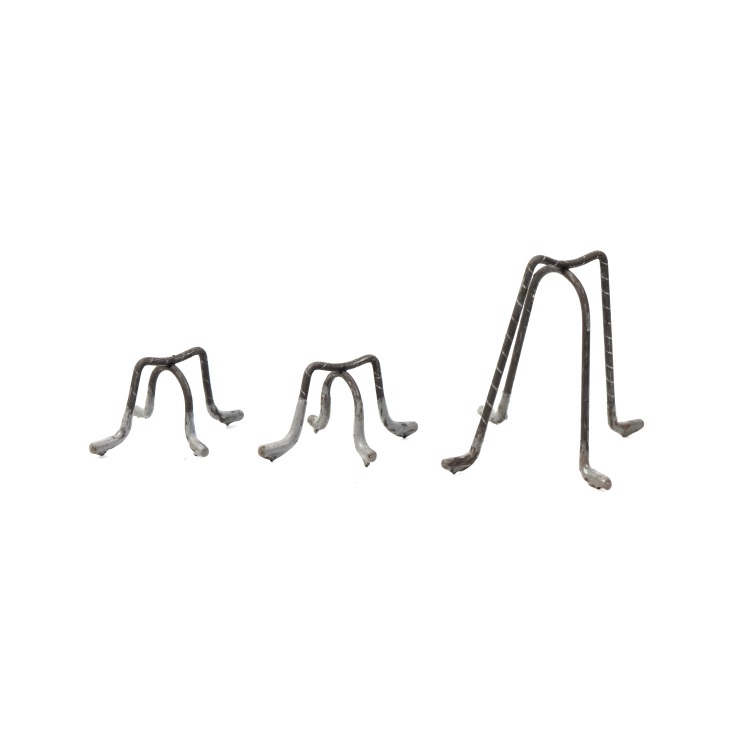

In the construction and manufacturing industries, fasteners play a crucial role in ensuring structural integrity and durability

. Among these fasteners, hot galvanized common nails stand out for their versatility and rust resistance. As a supplier in this field, it is essential to understand what makes these nails a preferred choice and how they can be utilized effectively in various applications.Hot galvanized nails undergo a process where they are coated with a layer of zinc to enhance their resistance to corrosion. This process involves immersing the nails in molten zinc, creating a metallurgical bond that provides a durable protective layer. As a result, hot galvanized common nails are ideal for outdoor applications or in environments where exposure to moisture is inevitable. They are commonly used in construction, roofing, fencing, and general woodworking projects.

One of the primary advantages of using hot galvanized common nails is their ability to withstand harsh weather conditions. In regions with high humidity or frequent rainfall, the zinc coating protects the steel from rust and corrosion, ensuring the longevity of the structure. This characteristic makes them a popular choice among builders and contractors who seek reliable and robust fasteners.

hot galvanized common nails supplier

Another factor contributing to the demand for hot galvanized common nails is their economical value. While the initial cost may be slightly higher than that of regular nails, their longevity and durability lead to lower maintenance costs and fewer replacements over time. As a supplier, it is important to highlight these benefits to clients, as they can make informed purchasing decisions based on long-term cost-effectiveness.

When choosing a supplier for hot galvanized nails, it is essential to consider the quality of the product. High-quality nails should conform to industry standards, ensuring that they meet safety and performance requirements. Additionally, a reputable supplier should offer a range of sizes and types of nails to cater to various project needs. Providing customers with a diverse selection helps ensure they find the right fastener for their specific applications.

Moreover, as a supplier, establishing strong relationships with manufacturers is vital. This allows for better quality control, timely delivery, and competitive pricing. Understanding the production processes and sourcing materials responsibly can also enhance the sustainability of the supply chain—an increasingly important factor for many customers today.

In conclusion, hot galvanized common nails are an essential component in the world of construction and manufacturing. Their rust-resistant properties, cost-effectiveness, and durability make them a favored choice among builders. As a supplier, staying informed about industry trends, maintaining product quality, and cultivating strong partnerships are crucial steps toward serving clients effectively. By providing high-quality hot galvanized nails, suppliers contribute to the success and longevity of numerous construction projects, elevating the standards of craftsmanship in the industry.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025