High-Quality Iron Wire Mesh Production from Leading Manufacturers in the Industry Today

Iron Wire Mesh Factory Crafting Strength and Versatility

In today’s industrial landscape, the demand for durable and reliable materials has never been higher. Among the essential products that cater to various sectors is iron wire mesh, a crucial component used in construction, agriculture, and numerous other applications. Iron wire mesh factories play a vital role in the production of this versatile product, ensuring that it meets the quality standards required by industries worldwide.

The Production Process

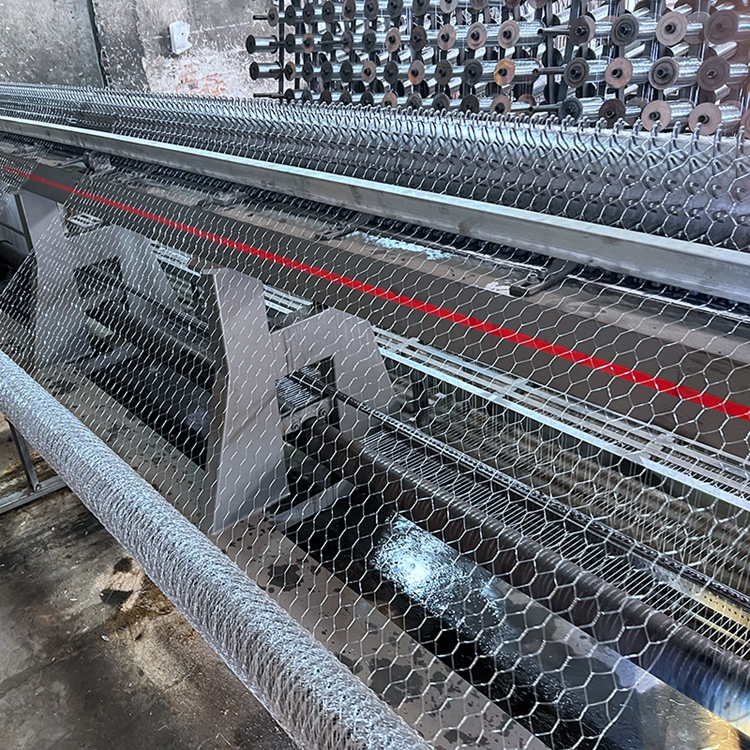

The journey of creating iron wire mesh begins with high-quality raw materials. Iron, known for its strength and malleability, is the primary component used in the manufacturing process. Factories often source iron in the form of wire rods, which undergo several stages of processing. The first step involves drawing the wire through a series of dies, reducing its diameter while increasing its length and tensile strength.

Once the wire is drawn, it is then woven or welded into mesh patterns. Different types of iron wire mesh can be produced depending on the intended application. For instance, welded wire mesh offers exceptional strength and serves well in applications such as reinforced concrete, while woven wire mesh provides flexibility and is often used in agricultural settings for fencing and animal enclosures. The factory's ability to produce various specifications of mesh not only caters to a diverse clientele but also showcases the adaptability of iron wire.

Quality Control

One of the hallmarks of a reputable iron wire mesh factory is its commitment to quality control

. Regular inspections during the production process are essential to eliminate defects and ensure that the final product can withstand the demands of its intended use. Factories employ advanced technology and skilled personnel to perform these inspections, focusing on parameters such as wire diameter, mesh opening size, and overall strength.Moreover, many factories are adopting international quality standards, such as ISO certifications, to enhance their credibility in the market. This adherence to strict quality norms not only boosts consumer confidence but also opens up avenues for exporting iron wire mesh to international markets.

iron wire mesh factory

Applications of Iron Wire Mesh

The applications of iron wire mesh are vast and varied. In construction, it is primarily used for reinforcing concrete structures, providing the necessary support to prevent cracking and improve durability. Simultaneously, in the agriculture sector, iron wire mesh finds its use in fencing, effectively keeping livestock secure and protecting crops from wildlife.

In industrial settings, iron wire mesh is widely applied in the manufacturing of filters, screens, and guards, due to its ability to withstand harsh conditions. Additionally, the automotive industry employs iron wire mesh for various components, highlighting its versatility across different fields.

Environmental Considerations

In recent years, the global emphasis on sustainability has led iron wire mesh factories to adopt eco-friendly practices. Many are now seeking ways to minimize waste during production and implement recycling processes for scrap metal. Innovations in manufacturing techniques also aim to reduce energy consumption, further contributing to environmental conservation.

Conclusion

The iron wire mesh factory stands as a testament to ingenuity and craftsmanship, providing essential materials that are foundational to numerous industries. With a commitment to quality, adaptability to market demands, and a focus on sustainable practices, these factories are not just producers but are pivotal players in the global economy. As the demand for versatile and reliable materials continues to rise, the significance of iron wire mesh factories will only grow, ensuring that they remain integral to construction, agriculture, and beyond.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025