High-Quality 0.9mm Black Annealed Wire for Versatile Applications in Construction and Manufacturing

Understanding 0.9mm Black Annealed Wire A Key Material in Various Industries

When it comes to industrial applications, the choice of materials plays a critical role in determining the quality and longevity of the final products. Among these materials, 0.9mm black annealed wire has garnered significant attention, particularly in industries like construction, manufacturing, and agriculture. This article will explore the properties, uses, and benefits of this versatile wire.

What is Black Annealed Wire?

Black annealed wire is a type of wire that has undergone an annealing process, which involves heating the wire to a specific temperature and then allowing it to cool slowly. This process alters the wire's structure, resulting in increased ductility- the ability to be stretched or deformed without breaking. The black in its name refers to the dark, oxidized finish that develops as a result of the alloying elements and the annealing process. Typically made from high-quality low carbon steel, the 0.9mm variant is favored for its balance between strength and flexibility.

Key Properties

1. Flexibility One of the primary advantages of 0.9mm black annealed wire is its remarkable flexibility. This makes it ideal for applications requiring bending or shaping without compromising the integrity of the wire.

2. Corrosion Resistance Although black annealed wire is not as corrosion-resistant as galvanized wire, it still offers decent resistance, especially when used in dry indoor environments. Its oxidized surface can aid in preventing further oxidation under certain conditions.

3. High Tensile Strength The wire exhibits good tensile strength, making it suitable for various applications where a robust solution is required.

4. Cost-effectiveness Compared to other materials, black annealed wire is relatively inexpensive, offering an economical solution for many manufacturing and construction needs.

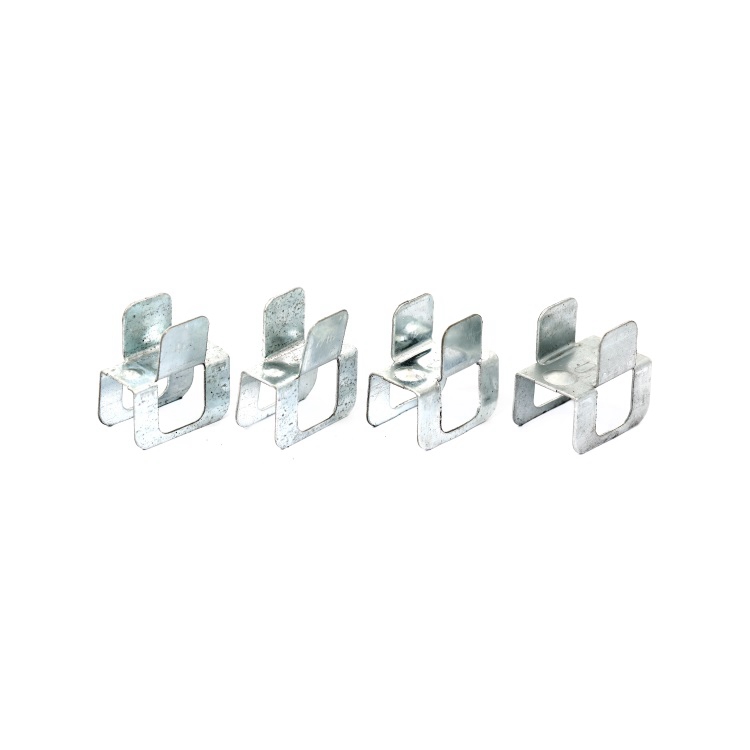

china 0.9mm black annealed wire

Common Applications

The versatile nature of 0.9mm black annealed wire has led to its widespread use across various sectors

1. Construction Industry In construction, this wire is often used for binding rebar or reinforcing materials. Its flexibility allows for secure and tight bindings, which can improve the overall strength of concrete structures.

2. Agricultural Uses Farmers utilize black annealed wire for fencing, trellising, and other agricultural applications. The wire's ability to withstand strain while maintaining its shape makes it ideal for supporting plants or enclosing livestock.

3. Manufacturing In manufacturing, this wire is used in the production of furniture, automotive parts, and other products requiring strong yet malleable wire.

4. Art and Crafts Artists and crafters often use 0.9mm black annealed wire for sculpting and creating intricate designs due to its easy-to-manipulate nature.

Conclusion

In conclusion, 0.9mm black annealed wire stands out as a fundamental material across a variety of industries. Its properties, including flexibility, tensile strength, and cost-effectiveness, make it a preferred choice among professionals. As industries continue to evolve, the demand for such versatile materials is likely to grow, underscoring the importance of understanding and utilizing black annealed wire effectively. Whether in construction, agriculture, or manufacturing, this wire proves to be an invaluable asset for achieving durability and efficiency in projects. Understanding its characteristics and applications will enable businesses and individuals to harness its full potential.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025