Electric Barbed Wire Manufacturing Processes and Industry Insights for Enhanced Security Solutions

The Evolution and Impact of Electric Barbed Wire Factories

Electric barbed wire has emerged as a critical innovation in the realm of security and fencing. Combining traditional barbed wire with electric technology, this product serves as an effective deterrent against intruders and unauthorized access. The establishment of electric barbed wire factories has been a significant development in this industry, catering to the increasing demand for enhanced security solutions in various sectors, from agriculture to military installations.

Historical Context

The concept of barbed wire dates back to the late 19th century, originally developed for agricultural fencing. As society progressed and crime rates began to rise, the need for heightened security measures became evident. The evolution from standard barbed wire to electric barbed wire started gaining momentum in the mid-20th century when the technological advancements made it feasible to incorporate electrical elements into fencing.

Electric barbed wire systems work by delivering a non-lethal electric shock to individuals who attempt to breach the fence, thus acting as a deterrent. The shock is designed to be strong enough to discourage trespassers without causing permanent harm. This dual-layer of physical barriers and electric deterrents provides a formidable security solution.

The Role of Factories

The establishment of electric barbed wire factories has played a pivotal role in meeting the rising demand for these security solutions. These factories are equipped with advanced machinery and skilled labor, allowing them to manufacture high-quality electric fencing products. The production process typically involves the following stages

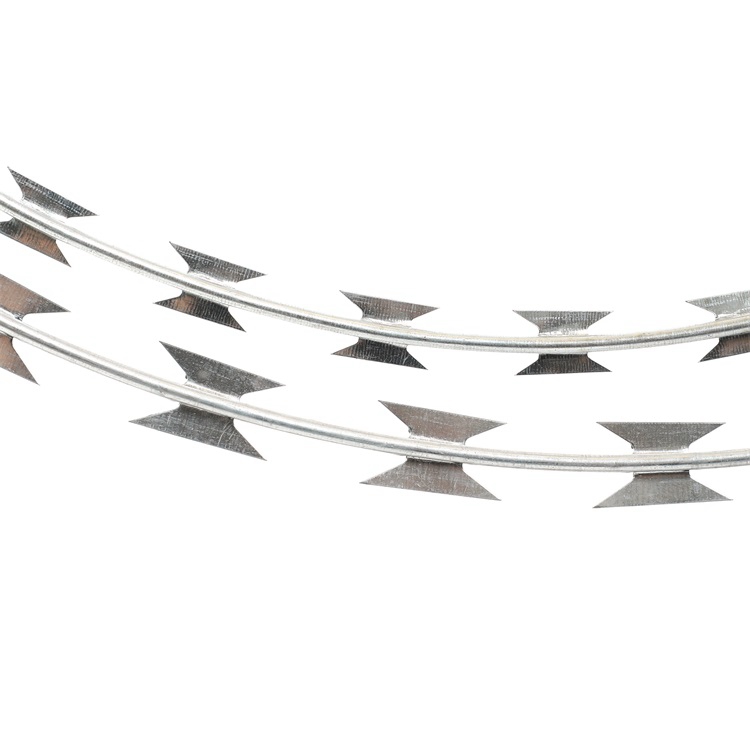

1. Material Sourcing Factories begin by sourcing high-grade materials that can withstand environmental factors while maintaining durability. Galvanized steel is commonly used for the barbed wire, ensuring resistance to corrosion and wear.

2. Manufacturing The manufacturing process involves weaving together the barbed wire with the electrical components. Factories often employ precision machinery to ensure the wires are produced at consistent thicknesses and that the barbs are strategically placed for maximum effectiveness.

3. Electrical Integration This step involves integrating the electric wiring, ensuring that it can deliver an adequate voltage. Safety measures are crucial during this stage to prevent accidental shocks to animals or authorized personnel.

electric barbed wire factories

4. Quality Control Before products leave the factory, they undergo stringent quality control processes. This includes testing the electric components and ensuring the physical integrity of the fences to meet safety standards.

5. Distribution Once products are manufactured and packaged, they are distributed to various sectors, including residential, commercial, and industrial clients.

Economic Impact

The rise of electric barbed wire factories has also led to economic growth in various regions. These factories create jobs, contribute to local economies, and drive technological innovation. They often work closely with research and development teams to enhance the effectiveness of their products through new technologies, such as solar-powered electric fencing.

Moreover, these factories play an essential role in the global supply chain for security solutions. As crime rates fluctuate around the world, the demand for effective security measures has seen an uptick, prompting factories to scale up production. This has also led to the export of electric barbed wire products to countries where security is increasingly important.

Environmental Considerations

As industries evolve, there is a growing concern for the environment. Electric barbed wire factories are now incorporating sustainable practices in their operations. This includes using recycled materials for production and implementing energy-efficient technology in manufacturing processes.

Additionally, there is a heightened awareness of the impact of security measures on local wildlife. Factories are working on developing designs that mitigate harm to non-target species while still providing effective security solutions.

Conclusion

Electric barbed wire factories have transformed the way security is approached in various sectors. Their evolution showcases not only advancements in technology but also a response to a growing need for safety in an increasingly complex world. As these factories continue to innovate and adapt, they solidify their role as essential players in the global security landscape, balancing effectiveness, economic growth, and environmental consciousness. Looking ahead, the future of electric barbed wire manufacturing promises continued advancements that will enhance our ability to protect both property and people.

-

Wire Mesh Solutions for Modern Industrial Needs

NewsJul.17,2025

-

Steel Wire Powers Modern Industrial Applications

NewsJul.17,2025

-

Iron Nails Big Iron Nail Price Guide Bulk Buyers

NewsJul.17,2025

-

Durable T Post Solutions for Industrial Fencing Projects

NewsJul.17,2025

-

Durable Hexagonal Wire Netting For Modern Applications

NewsJul.17,2025

-

Building Material Wholesale Solutions for Modern Construction Needs

NewsJul.17,2025