welded wire mesh factories

Understanding Welded Wire Mesh Factories Products, Processes, and Applications

Welded wire mesh is an essential material used across various industries, thanks to its versatility, strength, and cost-effectiveness. Welded wire mesh factories specialize in the production of this robust mesh, catering to a range of applications from construction to agriculture. In this article, we will explore the processes involved in the manufacturing of welded wire mesh, the benefits of using this material, and its diverse applications.

Manufacturing Process

The production of welded wire mesh involves several key steps

1. Material Selection The primary raw materials used in welded wire mesh production are steel wires, which can be coated with zinc for added corrosion resistance. This decision influences the final product's durability and longevity.

2. Wire Drawing Before the welding process begins, the steel wires are drawn into the desired thickness. This involves passing the steel through a series of dies, which reduce its diameter while increasing its length.

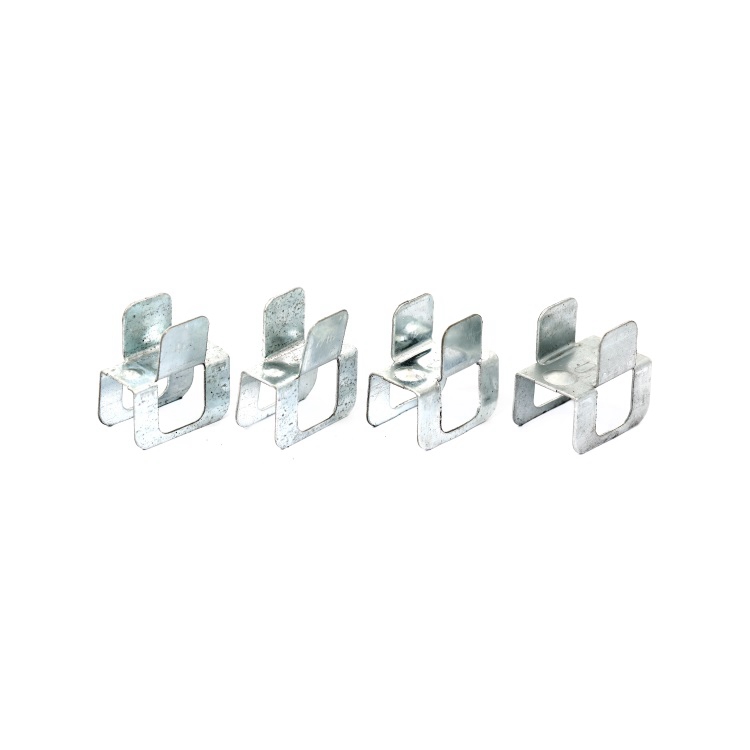

3. Welding The drawn wires are then aligned and welded together at their intersections. This process can be conducted using resistance welding, where an electric current is passed through the wires, generating heat at the joints and fusing them together. Automated welding machines are often employed to ensure precision and efficiency in this step.

4. Cutting and Rolling Once welded, the mesh sheets are cut to specified dimensions and can be rolled for easier transportation and handling. Factories often produce custom sizes based on client requirements.

5. Surface Treatment For enhanced durability, the welded wire mesh is often subjected to surface treatments such as galvanization or coating. Galvanization involves dipping the mesh in molten zinc, creating a protective layer that resists rust and corrosion.

6. Quality Control Before leaving the factory, the finished products undergo rigorous quality control checks. These inspections ensure that the mesh meets industry standards and client specifications, covering aspects like dimensions, strength, and surface finish.

Benefits of Welded Wire Mesh

Welded wire mesh offers several advantages, which contribute to its widespread use

1. Strength and Durability The welding process creates a strong and stable mesh that can withstand heavy loads and harsh environmental conditions.

welded wire mesh factories

3. Cost-Effectiveness Producing welded wire mesh is generally more economical compared to other reinforcement options, providing excellent value for construction and industrial projects.

4. Ease of Installation The prefabricated nature of welded wire mesh allows for quick and easy installation, saving time and labor costs on job sites.

5. Customizability Factories can produce welded wire mesh in a range of sizes, wire thicknesses, and coatings to suit specific client needs.

Applications of Welded Wire Mesh

The versatility of welded wire mesh leads to its application in numerous fields

1. Construction Commonly used as reinforcement for concrete slabs, beams, and walls, welded wire mesh enhances the structural integrity of buildings. It is also used for safety barriers and formwork.

2. Agriculture Farmers utilize welded wire mesh for fencing livestock, creating plant supports, and constructing enclosures for animals. Its durability and resistance to weathering make it ideal for outdoor use.

3. Industrial In industrial settings, welded wire mesh serves as partitions, shelving, and security fencing. Its strength is particularly beneficial in heavy-duty applications.

4. Architecture Welded wire mesh is used in architectural designs for aesthetically appealing structures, including facades and artistic installations.

5. Home Improvement DIY enthusiasts and contractors often use welded wire mesh for garden fencing, reinforcing patios, or creating decorative elements in landscaping.

Conclusion

Welded wire mesh factories play a crucial role in providing a versatile and robust material that meets the demands of various industries. The meticulous manufacturing process ensures high-quality products that stand the test of time. With its broad range of applications, welded wire mesh remains a staple in construction, agriculture, and beyond, highlighting its importance in modern infrastructure and design. As industries continue to evolve, the role of welded wire mesh will undoubtedly expand, paving the way for innovative uses and solutions.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025