tie wire gauge tie wire factories

Understanding Tie Wire Gauge and Factories A Comprehensive Overview

Tie wire, an essential component in construction and manufacturing, plays a crucial role in providing stability and structural integrity. This article provides a detailed insight into tie wire gauge, its specifications, and the factories that produce it.

What is Tie Wire?

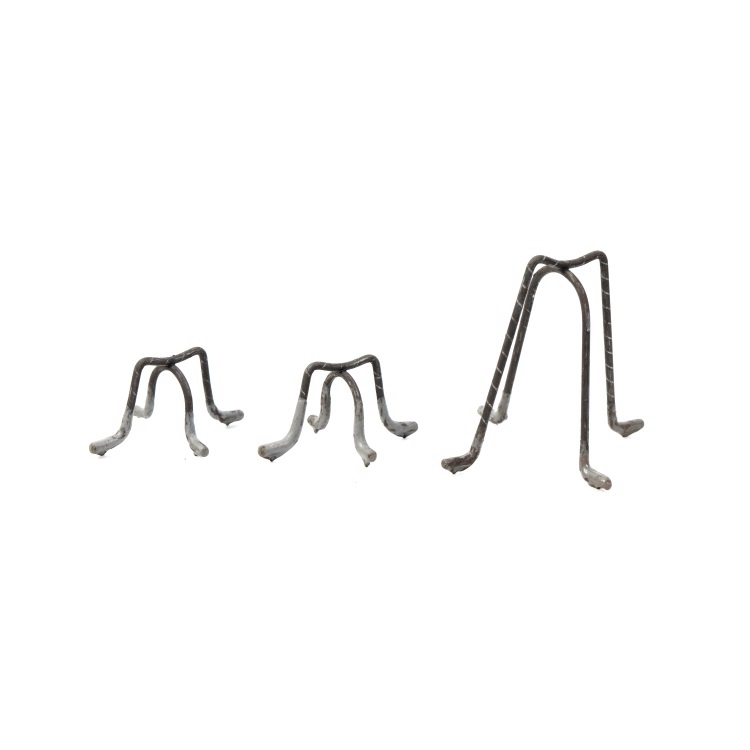

Tie wire is a type of wire used primarily in construction for binding and tying materials together, such as rebar (reinforcing bars). It is available in various materials, including steel, to suit different applications. The wire is designed to be durable and flexible, making it ideal for securing structural components in place during construction processes.

Tie Wire Gauge

The gauge of tie wire refers to its thickness, which affects its strength, flexibility, and suitability for various applications. The American Wire Gauge (AWG) system is commonly used to specify the thickness of wire. In this system, a lower gauge number indicates a thicker wire. For instance, a 12-gauge wire is thicker and stronger than a 16-gauge wire.

When selecting tie wire, factors such as the load it needs to carry, the environmental conditions (like moisture levels and temperature), and the specific binding requirements must be considered. Typically, tie wire gauges range from 8 to 18. For most construction applications, 16-gauge tie wire is commonly used, providing a good balance between strength and flexibility.

Manufacturing Processes in Tie Wire Factories

Tie wire factories employ various manufacturing processes to produce high-quality tie wire. These processes generally include

1. Wire Drawing This is the initial stage of production where raw wire (often in coils) is drawn through a series of dies to reduce its diameter and increase its length. The drawing process is critical for achieving the desired gauge and ensuring consistent quality.

tie wire gauge tie wire factories

2. Annealing After the wire is drawn, it often undergoes an annealing process, which involves heating the wire to a specific temperature and then allowing it to cool slowly. This process removes internal stresses and improves the wire's flexibility and ductility.

3. Coating Depending on the intended application, tie wire may be coated with materials such as galvanized zinc or plastic. Galvanization helps prevent rust and corrosion, making the wire long-lasting, especially in outdoor or humid environments.

4. Cutting and Packaging Finally, the wire is cut into specified lengths, coiled, and packaged for shipping. Proper packaging is essential to prevent tangling and damage during transportation.

Quality Control

Quality control plays a vital role in the manufacturing of tie wire, ensuring that the final product meets industry standards and client specifications. Factories routinely conduct tests for tensile strength, elongation, and corrosion resistance. Certifications may also be obtained to assure customers of the wire's quality and reliability.

The Importance of Tie Wire in Construction

Tie wire is indispensable in the construction industry. Its applications range from securing rebar in concrete foundations, aiding in masonry work, to providing stability for temporary structures. With the construction sector continuously evolving, so do the demands for innovative and versatile tie wire solutions.

Conclusion

Tie wire and its gauge specifications are crucial components of construction that ensure safety and structural integrity. The factories that manufacture tie wire employ various sophisticated processes to meet the diverse needs of the industry. With ongoing advancements in materials and production techniques, the future of tie wire looks promising, offering enhanced durability and performance for an array of construction applications. As the construction industry continues to grow, understanding the role and importance of tie wire will be essential for professionals aiming for excellence in their projects. Investing in high-quality tie wire is not just a matter of compliance; it is fundamental to the success and safety of construction endeavors worldwide.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025