Manufacturers of Straight Cut Tie Wire for Various Applications and Industries

The Demand for Straight Cut Tie Wire A Focus on Manufacturers

In the world of construction and manufacturing, efficient securing and binding mechanisms play a crucial role. One commonly overlooked yet essential component is tie wire, particularly straight cut tie wire. As a versatile and practical solution, straight cut tie wire serves numerous applications, from construction rebar tying to agriculture and fencing. This article explores the manufacturers of straight cut tie wire, their production processes, and the significance of choosing high-quality products for various industrial needs.

Understanding Straight Cut Tie Wire

Straight cut tie wire is typically made from high-quality steel, designed for strength and durability. The wire is manufactured to standard gauges, making it easy to handle and suitable for various applications. Its specific design allows for straightforward and secure tying of materials, which is crucial in construction projects where stability is paramount.

Manufacturers produce straight cut tie wire in different lengths and diameters, catering to the diverse requirements of their clients. This adaptability makes straight cut tie wire a preferred choice across multiple industries, including construction, agriculture, and even arts and crafts.

The Manufacturing Process

The production of straight cut tie wire involves several key steps. Initially, steel wire is drawn through a series of dies to achieve the desired thickness. This wire is then cut into standard lengths, which can vary based on the application. The manufacturing process also includes annealing, where the wire is heated and cooled to relieve internal stresses, enhancing its flexibility and reducing brittleness.

Quality control is an essential part of the manufacturing process. Leading manufacturers ensure that their straight cut tie wire meets industry standards and specifications. Rigorous testing is conducted to evaluate the wire's tensile strength, ductility, and overall performance. This commitment to quality guarantees that the wire can withstand the demands of heavy-duty applications, providing reliability and safety.

straight cut tie wire manufacturers

Key Manufacturers in the Market

Several manufacturers are renowned for their high-quality straight cut tie wire. Companies like Bekaert, WireCo WorldGroup, and J.F. Sieberichs have established themselves as significant players in this niche market. These companies invest in advanced manufacturing technologies and maintain high standards of production, ensuring that their products meet international quality certifications.

Moreover, many local manufacturers have emerged, providing competitive options without compromising on quality. These companies often cater specifically to regional markets, understanding local needs and preferences, thus ensuring timely deliveries and responsiveness.

Importance of Quality in Selection

When choosing a manufacturer for straight cut tie wire, it is crucial to consider several factors. First and foremost, the strength of the wire should be prioritized. High-quality tie wire can significantly impact the integrity of construction projects. Weak or inferior products may lead to structural failures, potential safety hazards, and increased costs in the long run.

Additionally, buyers should evaluate the manufacturer's reputation and customer service. Reliable manufacturers not only provide high-grade products but also support their clients through the purchasing process and beyond. This includes offering technical advice, responsive customer support, and adapting to specific order requirements.

Conclusion

In conclusion, straight cut tie wire is an indispensable product across various industries, playing a vital role in securing and binding materials. The process of selecting a manufacturer should involve a thorough evaluation of quality and reliability. With numerous established players in the industry, there is no shortage of options for businesses looking to source high-quality tie wire. By prioritizing robust materials and reputable manufacturers, companies across sectors can enhance their operational efficiency and ensure the success of their projects. Whether it's for construction, agriculture, or other uses, investing in superior straight cut tie wire is a decision that will yield lasting benefits.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

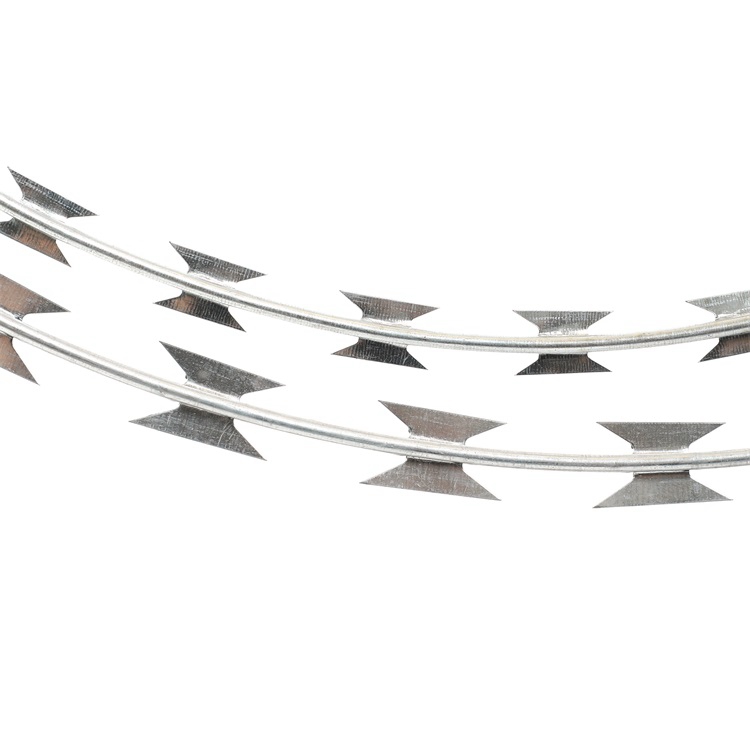

Enhance Your Security with Razor Wire

NewsJun.26,2025