Steel SAE 1006 Specifications for Common Nail Production and Manufacturer Guidelines

Understanding Steel SAE 1006 and Its Importance in Common Nail Manufacturing

In the realm of construction and manufacturing, the materials used significantly influence the quality and performance of the final products. One such material that holds a key position in the production of common nails is Steel SAE 1006. This low-carbon steel is known for its excellent ductility, weldability, and strength, making it an ideal choice for manufacturers.

What is Steel SAE 1006?

Steel SAE 1006 is classified as a low-carbon steel, which means it contains a carbon content up to 0.06%. This low carbon percentage contributes to the steel's remarkable properties. The American Society for Testing and Materials (ASTM) provides specifications for various steel grades, and SAE 1006 falls under the Society of Automotive Engineers (SAE) Steel Standards. It is primarily used in applications requiring high formability and moderate strength, which is precisely what nail production demands.

Properties of Steel SAE 1006

The properties of SAE 1006 make it suitable for the manufacturing of common nails. Its low carbon content enhances its malleability, allowing for easy shaping and forming during the manufacturing process. Additionally, it possesses good toughness, which helps nails maintain their structural integrity under stress when driven into materials like wood, concrete, or masonry.

Moreover, Steel SAE 1006 exhibits excellent cohesion when coated, making it beneficial for nails that require additional corrosion resistance. Coating treatments, such as galvanization, can prolong the lifespan of nails, making them suitable for various exposure conditions. This is crucial in construction applications where nails are often vulnerable to environmental elements.

Manufacturing Process

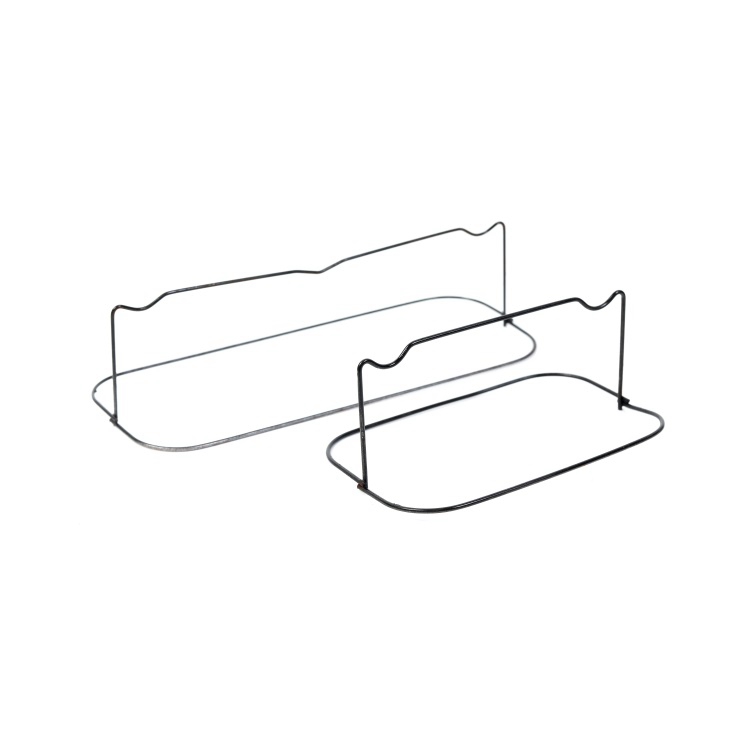

steel sae 1006 for common nail manufacturers

The manufacturing of nails from Steel SAE 1006 involves several stages. Initially, the steel is melted and shaped into wire using a process called wire drawing. The wire is drawn through successively smaller dies, which increases its length and reduces its diameter. Once the wire reaches the required thickness, it undergoes cutting, shaping, and point grinding processes to form individual nails.

During these processes, manufacturers pay close attention to the quality and consistency of the wire to ensure that the finished nails are defect-free and meet industry standards. Quality checks are crucial, as any flaws can lead to performance issues, such as bending or breaking, during use.

Applications of Common Nails

Common nails made from Steel SAE 1006 play a vital role in construction. They are widely used in framing, sheathing, and roofing applications, providing the necessary strength to hold structures together. Their capability to secure various building materials makes them indispensable in both residential and commercial construction.

Furthermore, the adaptability of Steel SAE 1006 means that it can be treated for specific applications. For example, nails designed for outdoor use are often coated to resist rust and corrosion, extending their durability. This versatility allows manufacturers to tailor their products to meet the specific needs of their clients, further enhancing the value of Steel SAE 1006.

Conclusion

Steel SAE 1006 stands out as a crucial material in the nail manufacturing industry due to its favorable properties, such as ductility, strength, and corrosion resistance. As construction projects continue to evolve, the demand for reliable and high-quality fasteners like common nails made from this low-carbon steel remains high. Nail manufacturers continually refine their processes and product offerings to meet industry standards and customer needs, ensuring that Steel SAE 1006 remains a fundamental choice in the construction landscape. As the industry advances, the role of SAE 1006 in creating dependable building solutions will undoubtedly persist, contributing to the integrity and longevity of structures built today.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025