square shank concrete nails in china factories

The Production and Significance of Square Shank Concrete Nails in Chinese Factories

In the world of construction and manufacturing, the importance of reliable fasteners cannot be overstated. One such essential fastener that has gained significant recognition in construction projects is the square shank concrete nail. These nails, primarily produced in factories across China, play a vital role in ensuring structural integrity and lasting durability in concrete applications.

Understanding Square Shank Concrete Nails

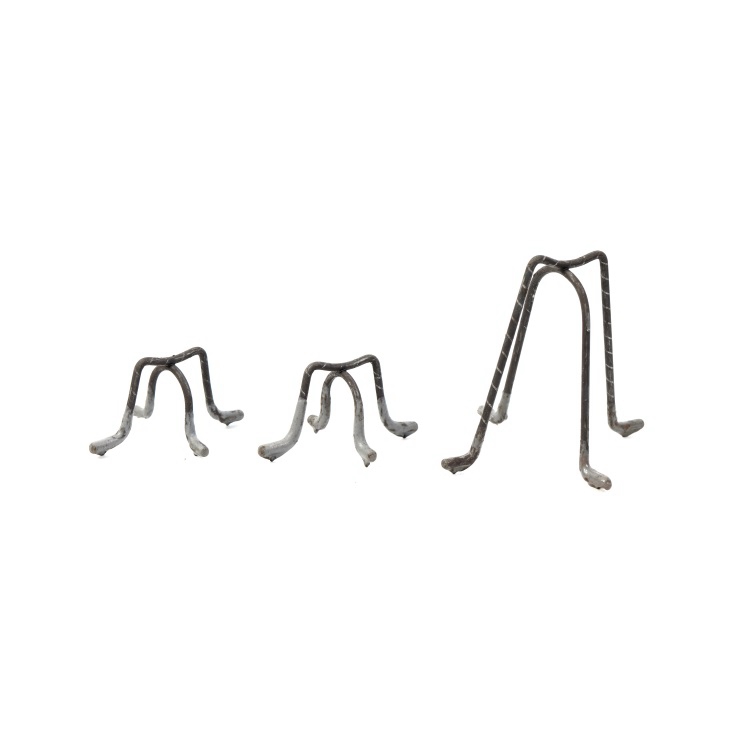

Square shank concrete nails are characterized by their square-shaped shafts, designed to offer better grip and torque when driven into concrete or masonry surfaces. Unlike traditional round shank nails, the square shank is specifically engineered to prevent the nail from spinning when hammered in, allowing for a secure fit. The design also ensures that the nail can withstand the shear forces that occur in various construction scenarios.

The Manufacturing Process

Chinese factories are renowned for their capacity to produce a vast array of hardware tools, including square shank concrete nails. The manufacturing process typically begins with the selection of high-quality steel, which offers strength and durability. This raw material is then transformed through a series of processes, including

1. Cutting and Shaping Steel rods are cut into desired lengths based on specific nail dimensions. The cutting process is followed by forming the nails, where the square shank is created through forging.

2. Heat Treatment To enhance the strength and resistance of the nails, heat treatment processes such as quenching and tempering are applied. These methods improve the nails' resilience against bending and breaking.

3. Surface Finishing Once the nails are shaped and treated, they undergo surface finishing to prevent rust and corrosion. Common treatments include galvanization or applying a protective coating, which significantly extends the lifespan of the nails, especially in high-moisture environments.

4. Quality Control Before packaging and distribution, rigorous quality control measures are implemented to ensure that each batch meets industry standards. This includes checking tensile strength, dimensional accuracy, and ensuring that the nails fit securely into the intended applications.

square shank concrete nails in china factories

Economic Importance

The production of square shank concrete nails in China is not just a matter of construction utility; it also plays a significant economic role. As one of the largest manufacturers of construction materials, China’s output of concrete nails contributes substantially to both domestic and international markets. With the growing demand for construction projects globally, the ability to produce these nails at scale has led to lucrative export opportunities.

Chinese manufacturers adopt advanced production technologies and efficient supply chain practices to stay competitive in the global market. This not only helps in keeping costs low but also ensures timely delivery, which is crucial for contractors and construction companies that depend on reliable supplies to maintain project schedules.

Application in Construction

Square shank concrete nails are extensively used in various construction applications, including

- Concrete Formwork Used to secure wooden forms when pouring concrete structures, ensuring that the formwork remains in place until the concrete sets.

- Masonry Work Essential for attaching wooden elements to masonry and concrete walls, providing a durable and robust fastening solution.

- Roofing and Siding Employed in fastening roofing materials and siding, ensuring that structures are well-anchored and weather-resistant.

Conclusion

In conclusion, square shank concrete nails produced in Chinese factories are not only vital components of the construction industry but also reflect the country's significant manufacturing capabilities. The combination of innovative production methods, stringent quality control, and a robust supply chain positions these nails as a staple in construction projects worldwide. As the construction industry continues to grow, so will the importance of high-quality fasteners like square shank concrete nails, underscoring their value in building safe and lasting structures. As stakeholders in the construction sector continue to seek reliable and efficient solutions, the demand for high-quality concrete nails will undoubtedly persist, fueling further advancements in manufacturing practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025