Self-Tapping Nails for Concrete Applications Manufacturers and Innovative Solutions

Self-Tapping Nails for Concrete An Essential Tool for Manufacturers

In the world of construction and manufacturing, the need for efficient and durable fastening solutions is paramount. Among the various types of fasteners, self-tapping nails designed specifically for concrete have gained a significant foothold. These nails provide a unique combination of strength, ease of use, and adaptability, making them an essential tool for manufacturers, builders, and contractors alike.

What Are Self-Tapping Nails for Concrete?

Self-tapping nails, as the name suggests, are nails that can create their own holes as they are driven into a material. When it comes to concrete, these nails are engineered to penetrate the dense and rigid surface, eliminating the need for pre-drilling holes. This characteristic not only saves time during the installation process but also reduces the risk of damaging surrounding structures. These nails are typically made from high-strength steel or other durable materials that can withstand the stresses associated with concrete applications.

Advantages of Using Self-Tapping Nails in Concrete

1. Time Efficiency The ability to eliminate the pre-drilling step means that projects can progress faster. Construction teams can move through tasks with greater speed, which is particularly advantageous in large-scale projects where time is of the essence.

2. Cost-Effectiveness With reduced labor time and fewer tools required (no need for drills), manufacturers can save on overall project costs. This financial benefit can be a significant factor for businesses aiming to maximize their profit margins.

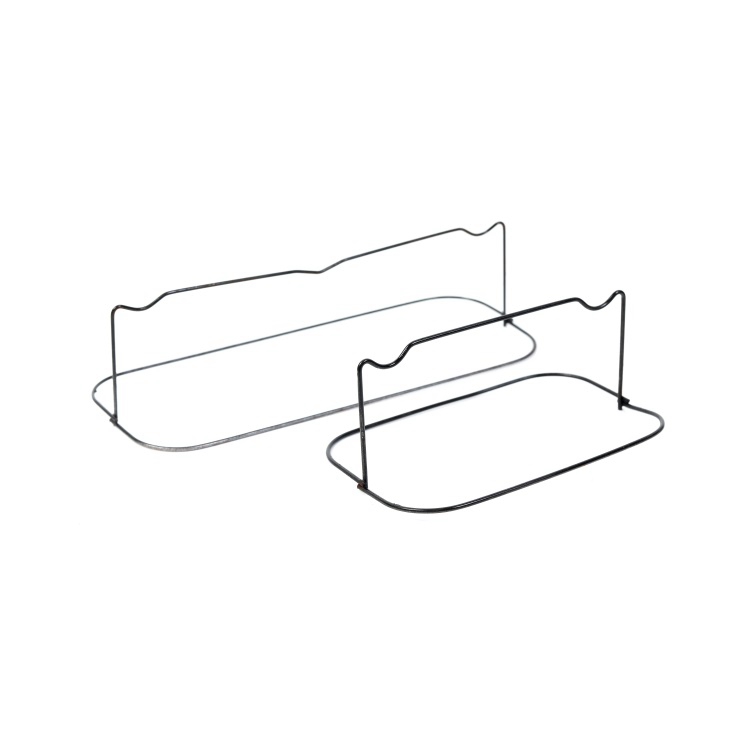

self-tapping nails for concrete manufacturers

3. Versatility Self-tapping nails are suitable for a variety of applications, ranging from securing wooden beams to anchoring fixtures and components in concrete walls. Their adaptability allows manufacturers to use a single type of fastener for multiple tasks, simplifying inventory management.

4. Strength and Durability These nails are designed to hold firmly in concrete, providing a secure and lasting hold. The materials used in manufacturing self-tapping nails ensure that they can withstand environmental factors, making them ideal for both indoor and outdoor applications.

Choosing the Right Manufacturer

When selecting self-tapping nails for concrete, it's crucial for manufacturers to choose a reliable supplier. Factors to consider include the quality of the materials used, the manufacturing standards adhered to, and the variety of options available. High-quality nails not only ensure optimal performance but also reduce the likelihood of failures, which can lead to costly repairs and project delays.

Furthermore, manufacturers should also consider the availability of technical support and guidance from suppliers. Knowledgeable suppliers can provide insights on the best practices for installation and selection, ensuring that the nails chosen are the best fit for the specific application.

Conclusion

Self-tapping nails for concrete are an indispensable tool in modern construction and manufacturing processes. Their time-saving, cost-effective, and versatile nature allows manufacturers to enhance productivity while ensuring quality. By choosing the right self-tapping nails and reliable suppliers, businesses can ensure that their projects are executed smoothly and efficiently, ultimately leading to greater success in a competitive market.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025