rebar tie wire coil factory

The Importance of Rebar Tie Wire Coils in Construction

In the realm of construction, ensuring structural integrity and durability is paramount. A critical component that enhances the stability of reinforced concrete is rebar, or reinforcement bars. To effectively combine these bars when creating concrete structures, the use of rebar tie wire coils has emerged as an essential practice. This article delves into the significance, characteristics, and applications of rebar tie wire coils, as well as insights into their manufacturing.

The Importance of Rebar Tie Wire Coils in Construction

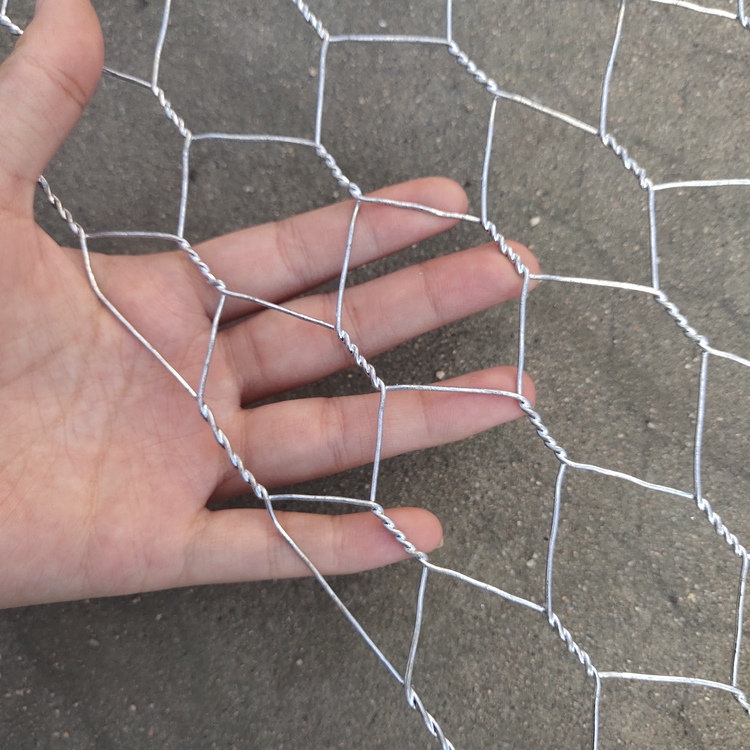

Typically made from galvanized or annealed steel wire, rebar tie wire offers excellent tensile strength and corrosion resistance. Galvanized wire, which is coated in zinc, provides added protection against rust, making it a preferred choice in environments where moisture and other corrosive elements are present. Annealed wire, on the other hand, is more pliable and easier to work with, allowing for quicker and more efficient tying processes, especially when the work involves complex rebar shapes.

rebar tie wire coil factory

The manufacturing process of rebar tie wire coils involves several stages. First, high-quality steel is selected and drawn into wire of the desired gauge. The wire is then treated to achieve the necessary strength and flexibility. Afterward, it is coiled into convenient bundles, facilitating easy transport and usage on construction sites. Factories producing these coils maintain rigorous quality control measures to ensure that the wire meets industry standards and can withstand the stresses of construction environments.

In terms of application, rebar tie wire coils are indispensable across various construction projects, including residential buildings, bridges, highways, and industrial structures. The versatility of the wire allows it to be used in diverse settings, catering to different rebar sizes and configurations. Moreover, construction teams benefit from the time-saving aspects of using rebar tie wire. It is not only easy to apply, but it also significantly expedites the entire process of setting up reinforcement frameworks.

As sustainability becomes an increasingly pressing concern within the construction industry, many manufacturers are exploring eco-friendly practices, such as recycling steel for wire production. This not only reduces waste but also lowers the carbon footprint associated with new steel production. Consequently, the trend toward sustainability is reshaping the way factories operate, emphasizing the need for responsible sourcing and efficient use of resources.

In conclusion, rebar tie wire coils are a fundamental element in modern construction, ensuring the structural integrity and longevity of concrete structures. With their strength, versatility, and ease of use, these coils play a vital role in the reinforcement process, underscoring their importance in successful construction practices. As the industry continues to evolve, the focus on quality, sustainability, and efficiency in the manufacturing of rebar tie wire will undoubtedly remain a top priority for factories worldwide.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025