Properties and Applications of Pure Iron Nails in Various Industries

The Fascinating Journey of a Pure Iron Nail

In the bustling world of construction and crafts, one humble object often goes unnoticed the pure iron nail. This seemingly simple tool plays an essential role in our daily lives, serving as the backbone for various constructions ranging from the tiniest wooden crafts to massive structural projects.

Pure iron, as the name suggests, is iron that is free from significant impurities, predominantly carbon. This high level of purity grants the metal unique properties, among which are its excellent ductility, malleability, and magnetic characteristics. In terms of mechanical strength, pure iron may not be the strongest metal; however, its ability to handle stress and deform without breaking makes it ideal for creating nails.

The process of making a pure iron nail begins with the extraction of iron ore, predominantly found in nature as hematite or magnetite. The ore is heated in a blast furnace, where it undergoes chemical transformations, resulting in molten iron. This molten iron is then purified and cast into ingots, allowing manufacturers to produce various iron goods, including nails. The production process emphasizes techniques aimed at minimizing impurities, ensuring the final product retains as much of the innate properties of pure iron as possible.

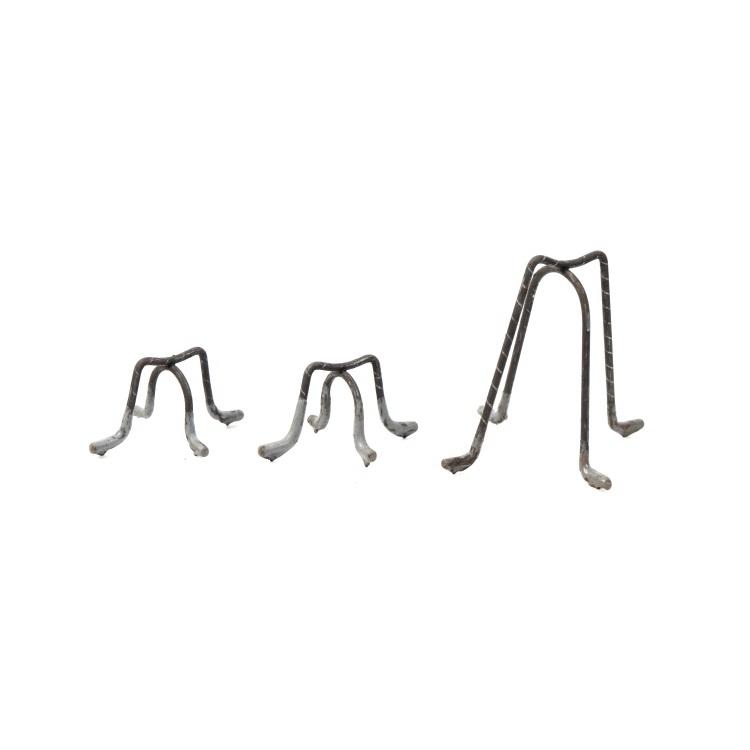

pure iron nail

Once the pure iron is ready, it is shaped into nails through forging—a process that involves hammering the heated iron into a desired form. This method not only shapes the metal but also enhances its strength through work hardening. Depending on their intended use, nails can be produced in various sizes and lengths, from tiny brads used in intricate woodworking to heavy-duty spikes designed for construction purposes.

The advantages of pure iron nails extend beyond their physical characteristics. One notable aspect is their ability to corrode over time, which can be detrimental in many applications. However, this property can also be beneficial, as the gradual oxidation helps create a protective layer of rust. This layer aids in preventing further corrosion of the underlying metal, especially when nails are embedded in wood, where exposure to moisture can be an issue.

Two typical applications of pure iron nails are in the building and woodworking industries. In construction, they are widely used to fasten beams and supports, ensuring structural integrity. Meanwhile, in woodworking, these nails provide the strength required to hold pieces together without splitting the wood.

In conclusion, while a pure iron nail may seem insignificant, its journey from raw ore to a finished product is a remarkable testament to both nature’s bounty and human ingenuity. Whether in a humble piece of furniture or a grand architectural masterpiece, these nails are an integral part of our built environment, reminding us of the intricate connections that lie within the simplest objects.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025