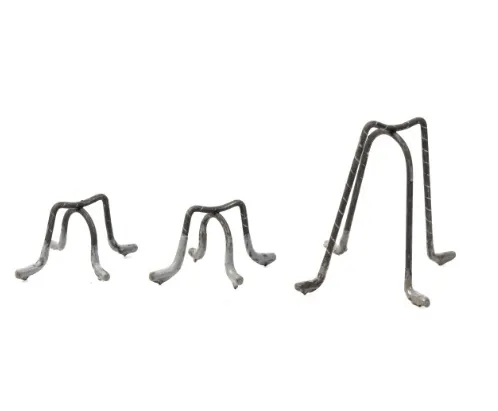

Premium Continuous Deck Rail Slab Bolster Solutions

For modern construction projects requiring precise concrete reinforcement and spacing, slab bolster products offer unmatched efficiency and durability. As a leading wholesaler of construction materials, we specialize in high-quality concrete bolsters designed to meet the demands of commercial and industrial concrete work. This comprehensive guide explores the features, benefits, and applications of continuous deck rail slab bolster systems, helping contractors and project managers make informed purchasing decisions for their concrete reinforcement needs.

Why Choose Slab Bolster Upper for Concrete Construction?

The slab bolster upper system has revolutionized modern concrete construction through its innovative design and superior performance characteristics. These specialized concrete bolsters provide continuous, uniform support for rebar mats throughout the entire slab area, ensuring consistent concrete coverage that meets strict building code requirements. The durable high-density polyethylene construction of premium rebar bolsters offers exceptional resistance to corrosion, chemicals, and UV exposure, making them suitable for both interior and exterior concrete applications. Contractors particularly value slab bolster systems for their ability to significantly reduce installation time compared to traditional individual spacers - a single worker can install hundreds of linear feet in minimal time. The continuous rail design maintains precise rebar positioning even under heavy construction traffic and concrete pouring operations, preventing the shifting and settling that can compromise structural integrity. For concrete contractors working on large-scale commercial projects, the efficiency gains provided by slab bolster upper systems translate directly into reduced labor costs and faster project completion times. The interlocking mechanism allows for easy length adjustment and secure connections between sections, creating a stable support network that remains intact throughout the entire concrete placement process.

Key Features of High-Performance Concrete Bolsters

Professional-grade concrete bolsters incorporate several important design features that ensure reliable performance in demanding construction environments. The continuous rail configuration of slab bolster systems eliminates the weak points and inconsistencies associated with individual spacers, providing uninterrupted support along the entire rebar mat. High-impact polypropylene construction gives premium rebar bolsters the durability to withstand heavy equipment traffic during concrete placement without cracking or breaking. Standard product lengths typically range from 2 feet to 10 feet, with many manufacturers offering custom lengths to accommodate unique project requirements. The innovative locking mechanism on slab bolster upper products allows for quick length adjustments and secure connections between sections, maintaining system integrity during the most vigorous concrete pours. The pointed tip design minimizes contact surface with formwork while ensuring precise concrete cover specifications are maintained - an essential feature for quality-conscious contractors. Many advanced concrete bolsters now incorporate measurement markings along the rail length, allowing installers to verify proper spacing and alignment during placement. The lightweight yet rigid construction of modern slab bolster systems makes them easy to handle and install while providing sufficient strength to support heavy rebar grids without bending or sagging.

Applications of Rebar Bolsters in Concrete Construction

The versatility of rebar bolsters makes them indispensable across a wide range of concrete construction applications where precise reinforcement positioning is critical. In commercial building projects, slab bolster systems are extensively used for floor slabs, parking decks, and elevated platforms that require consistent rebar spacing and reliable concrete coverage. Infrastructure developments including bridge decks, highway overpasses, and tunnel linings benefit from the durability and precision offered by concrete bolsters in these demanding applications. Tilt-up construction operations utilize slab bolster upper products to maintain exact reinforcement positioning in wall panels that will be lifted into vertical position. Precast concrete manufacturers rely on rebar bolsters for efficient, standardized production of concrete elements that require uniform quality and consistent reinforcement placement. Industrial flooring applications, particularly those in manufacturing facilities and warehouses, employ slab bolster systems to ensure proper rebar positioning in slabs that will endure heavy loads and constant traffic. The construction industry's growing emphasis on efficiency and precision has driven increasing adoption of concrete bolsters as contractors recognize their ability to reduce labor costs while improving structural integrity in finished concrete work. Water treatment plants and marine structures particularly benefit from the corrosion-resistant properties of plastic rebar bolsters in these challenging environments.

Benefits of Wholesale Slab Bolster Procurement

Purchasing slab bolster products through established wholesale channels provides concrete contractors and construction firms with significant operational and financial advantages. Bulk acquisition of concrete bolsters typically yields 20-35% cost savings compared to retail purchases, with the economies of scale being particularly beneficial for large projects requiring extensive linear footage. Reputable wholesale suppliers maintain comprehensive inventories of rebar bolsters in all standard lengths and configurations, ensuring immediate availability to keep construction schedules on track. Direct manufacturer relationships available through wholesale channels enable customization of slab bolster upper products including special lengths, reinforced versions for extra-heavy applications, and proprietary formulations for extreme environments. Volume purchasing typically includes valuable professional services such as technical support, project-specific consultation, and efficient logistics solutions for delivering large slab bolster orders to job sites. Rigorous quality assurance protocols at the wholesale level guarantee that all concrete bolsters meet or exceed relevant industry standards for load capacity, durability, and performance specifications. Many wholesale suppliers offer just-in-time delivery programs for rebar bolsters, coordinating shipments with project phases to minimize on-site storage requirements. Established wholesale partnerships often provide access to innovative slab bolster system enhancements and proprietary product improvements before they reach general distribution channels.

Slab Bolster Systems FAQ

What length options are available for slab bolster products?

Standard slab bolster lengths range from 2 to 10 feet in increments, with many manufacturers offering custom lengths up to 20 feet for specialized concrete applications requiring continuous support.

How does slab bolster upper compare to individual spacers for concrete work?

The continuous slab bolster upper system provides more uniform support, faster installation (typically 3-4 times quicker), and greater stability during concrete placement compared to traditional individual concrete bolsters.

What weight capacity do professional rebar bolsters support?

High-quality rebar bolsters from reputable manufacturers typically support construction loads up to 300-400 pounds per linear foot, maintaining precise rebar positioning even under heavy equipment traffic during concrete placement.

Can slab bolster products be reused on multiple projects?

Yes, premium plastic slab bolster systems are engineered for multiple reuse cycles when properly cleaned and stored between projects, with high-grade polypropylene versions often lasting through 8-10 construction cycles.

Why should contractors source concrete bolsters from wholesale suppliers?

Wholesale procurement of concrete bolsters ensures the best combination of price, quality, and availability, with access to professional-grade rebar bolsters that meet exacting construction specifications and bulk purchase discounts unavailable through retail channels.

-

Discount 16 d Common Nails - Bulk, Durable, Fast Shipping

NewsNov.17,2025

-

Finish Nails - Durable, Rust-Resistant, Clean Countersink

NewsNov.17,2025

-

Barbed Wire: Galvanized, High-Tensile Security Fencing

NewsNov.17,2025

-

Discount 16 d Common Nails – Bulk, Durable, OEM Options

NewsNov.17,2025

-

Welded Steel Tube Temporary Fence – Galvanized, Durable

NewsNov.04,2025

-

Barbed Wire – High-Tensile, Galvanized, Bulk & Fast Shipping

NewsNov.04,2025