price gabion wire mesh factories

Understanding Price Trends in Gabion Wire Mesh Factories

Gabion wire mesh has emerged as a crucial material in multiple sectors, including construction, landscaping, and civil engineering. As the demand for eco-friendly and sustainable building solutions grows, so too does the significance of understanding pricing trends within the gabion wire mesh manufacturing industry.

Gabions, typically defined as wire mesh containers filled with rock or concrete, serve a myriad of purposes, including erosion control, slope stabilization, and even as decorative elements in landscaping. The versatility and cost-effectiveness of gabion structures make them increasingly popular. However, as with any product, the price of gabion wire mesh can vary significantly based on a variety of factors.

Key Factors Influencing Prices

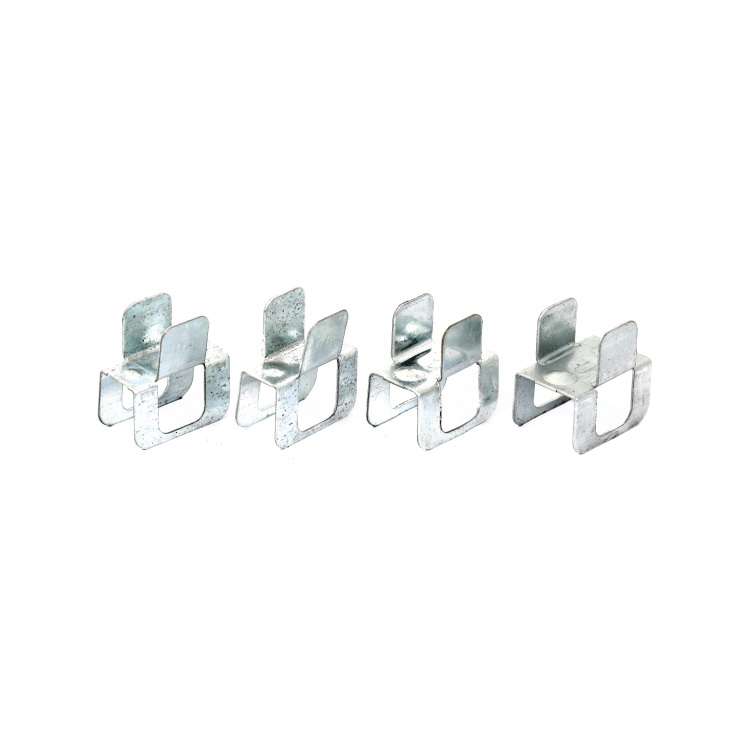

1. Material Quality The type of wire used in gabion mesh significantly affects its pricing. Galvanized wire, which is treated to resist corrosion, tends to be more expensive than untreated wire. Additionally, the thickness of the wire plays a crucial role; thicker wire generally translates to higher costs, but it also offers better durability and strength.

2. Manufacturing Processes Different manufacturers employ various techniques and technologies in the production of wire mesh. Factories that invest in advanced equipment may have higher operational costs, which can lead to elevated final prices for consumers. Conversely, manufacturers using simpler, more traditional methods may offer lower prices but potentially at the cost of quality.

3. Supply Chain Dynamics The sourcing of raw materials is another pivotal factor in pricing. Fluctuations within the steel market, transportation costs, and even geopolitical considerations can drastically influence the price of wire mesh. As steel prices rise due to increased global demand or supply chain disruptions, manufacturers often pass these costs onto consumers.

price gabion wire mesh factories

4. Market Demand Seasonal variations in demand can also affect prices. For instance, a spike in construction projects during warmer months can lead to increased demand for gabion wire mesh, with corresponding price hikes. Conversely, during economic downturns, demand may decline, resulting in competitive pricing from manufacturers eager to maintain their market share.

5. Customization and Size Gabion wire mesh is often customized to meet specific project requirements, whether in terms of size, shape, or mesh configuration. Custom products typically bear higher prices compared to standard sizes due to added production costs. Buyers must weigh their specific needs against budget considerations.

The Role of Quality Control

It's essential to consider that price is not the sole indicator of product quality. Reputable wire mesh manufacturers frequently engage in stringent quality control processes to ensure their products meet industry standards. Thus, while exploring price options, buyers should also evaluate the manufacturer's certifications, industry reputation, and reviews from previous clients.

Making Informed Decisions

For those looking to purchase gabion wire mesh, research is key. Compare prices from different factories while taking into account the quality of material, manufacturing processes, and customer service. Additionally, seeking quotes from multiple suppliers can provide a clearer picture of the market landscape.

In conclusion, understanding the pricing mechanisms of gabion wire mesh factories requires a comprehensive view of various influencing factors. As the industry evolves, maintaining awareness of these elements will empower buyers to make informed and economically sound purchasing decisions in this growing market.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025