plastic rebar support chair 1/2" exporter

Understanding Plastic Rebar Support Chairs An Exporter's Perspective

In the world of construction and civil engineering, the significance of rebar (reinforcing bar) cannot be overstated. It is the backbone of reinforced concrete structures, offering tensile strength and structural integrity. However, to maximize the effectiveness of rebar, proper placement and support are crucial. This is where plastic rebar support chairs come into play. As an exporter of these essential components, it is important to understand their value, functionality, and the global market dynamics surrounding their use.

What are Plastic Rebar Support Chairs?

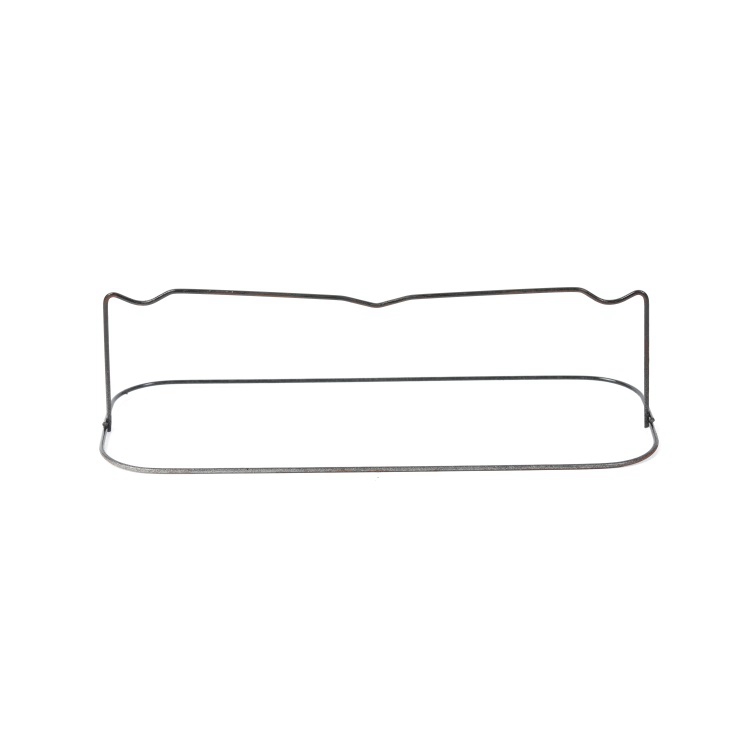

Plastic rebar support chairs are specialized accessories designed to hold reinforcing bars in position during concrete placement. They are typically made from high-density polyethylene (HDPE) or polypropylene, materials that offer durability, corrosion resistance, and lightweight properties. These chairs are essential in ensuring that rebar is placed at the correct height and alignment, facilitating proper concrete coverage around the bars. They come in various sizes, including the commonly used 1/2 chair, catering to different rebar diameters and construction requirements.

Key Advantages of Plastic Support Chairs

1. Corrosion Resistance Unlike metal supports, plastic chairs do not corrode over time. This is particularly advantageous in environments where moisture and chemicals can lead to deterioration, thereby extending the lifespan of the concrete structure.

2. Lightweight and Easy to Handle The lightweight nature of plastic makes these chairs easier to transport and install on site. Construction workers can manage and position them quickly, optimizing workflow and productivity.

3. Cost-Effectiveness Although the initial cost of plastic support chairs may be slightly higher than metal counterparts, their durability and resistance to environmental factors can lead to long-term savings in maintenance and repair costs.

4. Eco-Friendly Options As sustainability becomes increasingly important in construction, many manufacturers are producing plastic rebar support chairs from recycled materials. This not only reduces waste but also appeals to environmentally conscious buyers.

Market Demand and Export Potential

plastic rebar support chair 1/2" exporter

The demand for plastic rebar support chairs has been steadily increasing due to the global construction boom. With rapid urbanization, infrastructure development, and an emphasis on sustainable building practices, the market for these products is vast. Countries with emerging economies, particularly in Asia, Africa, and South America, present significant opportunities for exporters.

As an exporter, understanding the market dynamics is vital. Factors such as quality, price, brand reputation, and after-sales service play an important role in a buyer’s decision-making process. Establishing strong relationships with distributors and contractors in target markets can lead to increased sales and brand loyalty.

Quality Control and Compliance

For exporters, ensuring the quality of plastic rebar support chairs is paramount. Compliance with international standards, such as ISO certifications, is often a requirement for gaining access to certain markets. Conducting rigorous quality control checks during the manufacturing process ensures that the products meet the necessary specifications.

In addition, staying updated with the latest regulations and environmental standards in different countries is crucial. For instance, some regions may impose restrictions on the types of plastics used in construction materials, necessitating strong compliance strategies to avoid costly penalties or product recalls.

The Future of Plastic Rebar Support Chairs

As technology continues to advance, the manufacturing process of plastic rebar support chairs is expected to evolve. Innovations such as 3D printing and the use of composite materials may soon offer even more options for builders. Furthermore, the growing emphasis on sustainable construction practices is likely to influence product development, encouraging manufacturers to create environmentally friendly options.

As an exporter in this competitive market, staying ahead of these trends is essential. Investing in research and development, exploring new markets, and leveraging digital marketing strategies can significantly enhance a company’s presence and profitability.

Conclusion

In summary, plastic rebar support chairs, including the popular 1/2 variety, play a crucial role in the construction industry. Their advantages, such as corrosion resistance, lightweight structure, and eco-friendliness, make them an attractive choice for builders worldwide. For exporters, understanding market demands, ensuring compliance, and innovating for the future will be key to capitalizing on the growing opportunities in this sector. As global construction evolves, plastic rebar support chairs will undoubtedly continue to be a fundamental component in building durable and sustainable structures.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025