Price List for Plastic Coated Welded Wire Mesh Rolls

Understanding Plastic Coated Welded Wire Mesh Roll Pricing

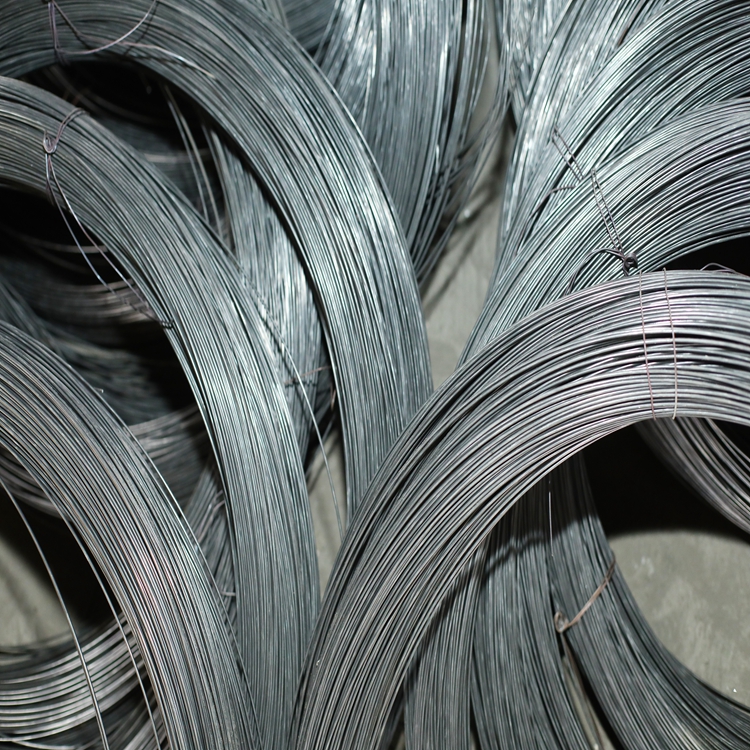

Plastic coated welded wire mesh rolls are versatile products commonly used across various industries due to their combination of strength, durability, and resistance to corrosion. These mesh rolls are ideal for applications such as fencing, animal enclosures, garden protection, and even construction. When considering purchasing these products, it’s crucial to understand the factors that influence their pricing.

The price of plastic coated welded wire mesh rolls can vary significantly based on several key factors. One of the primary determinants is the gauge (thickness) of the wire used. Thicker wires typically provide greater strength and durability but may come at a higher cost. Additionally, the width and height of the roll also affect pricing; larger rolls will generally be more expensive due to the increased amount of material used.

Another essential factor is the type of plastic coating applied to the wire. PVC (polyvinyl chloride) is the most common coating, providing a robust barrier against environmental elements. The quality and thickness of this coating can influence the overall cost of the mesh roll. Rolls with a thicker coating are often more resistant to wear and tear, making them a more prudent investment in the long run.

Supply and demand dynamics in the market also play a critical role in determining prices. An increase in demand for plastic coated welded wire mesh rolls—due, perhaps, to heightened construction activity or growing agriculture practices—can lead to higher prices. Conversely, if production exceeds market demand, prices may drop. It’s essential for buyers to monitor market trends to make informed purchasing decisions.

plastic coated welded wire mesh roll pricelist

Moreover, geographical location can impact the cost of these mesh rolls. In regions where the raw materials for manufacturing these products are readily available, buyers may benefit from lower prices. Shipping costs also come into play, especially if the product needs to be transported over long distances.

Bulk purchasing can provide price advantages. Many suppliers offer discounts for larger orders, which can make a significant difference for businesses looking to buy in volume. It’s advisable for buyers to negotiate pricing with suppliers to secure the best deal.

Lastly, it’s important to consider the reputation and reliability of the manufacturer. Established companies with a track record of quality products may charge a premium, but their offerings often promise better durability and performance. Investing in quality products can save money in the long run through reduced maintenance and replacement costs.

In conclusion, while there are many factors affecting the price of plastic coated welded wire mesh rolls, understanding these can help consumers make informed choices. Evaluating thickness, coating type, market conditions, geographical factors, bulk buying options, and manufacturer reputation will ensure that buyers obtain quality products at competitive prices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025