Feb . 18, 2025 08:17

Back to list

discount 16 d common nails

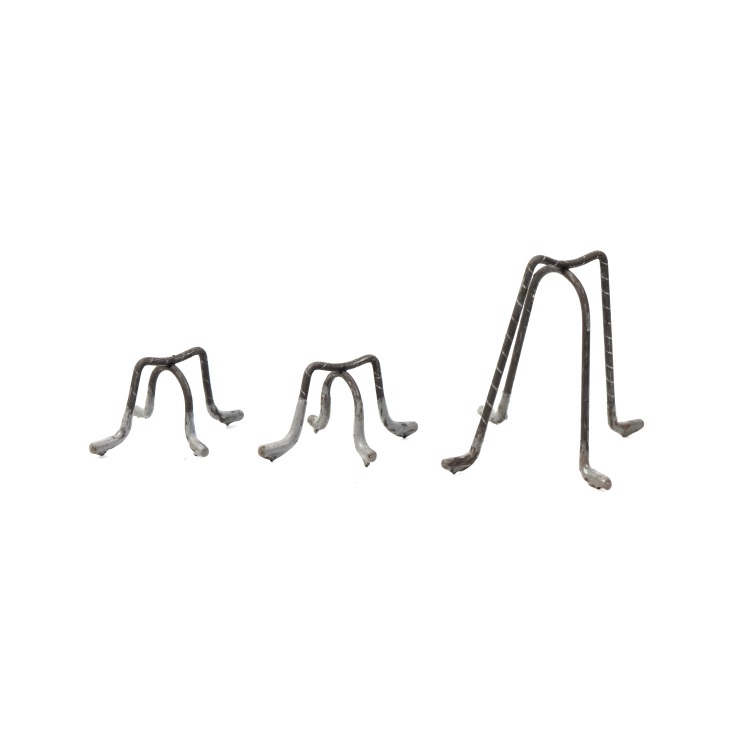

When selecting the right nails for various construction or DIY projects, penny hot galvanized common nails often rise to the occasion. These nails, distinguished by their galvanized coating, are invaluable for a diverse range of applications, from building wooden structures to smaller carpentry tasks. Their design and treatment allow them to offer both strength and resistance to environmental factors, making them a staple in the toolkits of professionals and hobbyists alike.

The authoritative nature of penny hot galvanized common nails is further supported by industry standards and compliance. Often manufacturing adheres to strict guidelines that ensure each nail meets specific mechanical and chemical properties. Such adherence not only enhances the nail's reliability but also provides an assurance of quality to users. This assurance is critical in maintaining trust, as builders rely on these nails to meet both regulatory standards and client expectations. Moreover, the trustworthiness of penny hot galvanized nails extends beyond their physical makeup. Reputable manufacturers provide extensive product warranties, reflecting their confidence in the product’s performance over time. Feedback and testimonials from seasoned builders attest to these nails’ reliability, with positive word-of-mouth serving as a strong endorsement within the building community. Furthermore, environmental considerations are increasingly relevant in product selection today. Hot-dip galvanized nails offer a sustainable option, given the longevity and reduced waste they contribute through their extended life cycle. A well-constructed project, made with lasting materials like these nails, minimizes the need for repairs or replacements – an aspect critically valued in eco-conscious construction practices. In conclusion, penny hot galvanized common nails epitomize a balance of strength, durability, and practicality. When a product seamlessly combines such attributes while maintaining a consistent demand across various construction applications, it secures its position not just as a tool of choice, but as a trusted ally in any builder’s collection. Whether you are an experienced builder or a DIY enthusiast, these nails promise to deliver in reliability and efficiency, evident in successful projects that stand the test of time.

The authoritative nature of penny hot galvanized common nails is further supported by industry standards and compliance. Often manufacturing adheres to strict guidelines that ensure each nail meets specific mechanical and chemical properties. Such adherence not only enhances the nail's reliability but also provides an assurance of quality to users. This assurance is critical in maintaining trust, as builders rely on these nails to meet both regulatory standards and client expectations. Moreover, the trustworthiness of penny hot galvanized nails extends beyond their physical makeup. Reputable manufacturers provide extensive product warranties, reflecting their confidence in the product’s performance over time. Feedback and testimonials from seasoned builders attest to these nails’ reliability, with positive word-of-mouth serving as a strong endorsement within the building community. Furthermore, environmental considerations are increasingly relevant in product selection today. Hot-dip galvanized nails offer a sustainable option, given the longevity and reduced waste they contribute through their extended life cycle. A well-constructed project, made with lasting materials like these nails, minimizes the need for repairs or replacements – an aspect critically valued in eco-conscious construction practices. In conclusion, penny hot galvanized common nails epitomize a balance of strength, durability, and practicality. When a product seamlessly combines such attributes while maintaining a consistent demand across various construction applications, it secures its position not just as a tool of choice, but as a trusted ally in any builder’s collection. Whether you are an experienced builder or a DIY enthusiast, these nails promise to deliver in reliability and efficiency, evident in successful projects that stand the test of time.

Share

Latest news

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025