OEM Pallet Nailing Station for Efficient Woodworking Production

The Essential Role of OEM Pallet Nailing Tables in Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. One of the key components that contribute to streamlined operations in the wood product industry is the OEM pallet nailing table. These tables are specifically designed for the automated assembly of pallets, which are crucial for shipping and storage across various sectors. This article delves into the significance of OEM pallet nailing tables, their features, and the benefits they provide.

Understanding OEM Pallet Nailing Tables

OEM, or Original Equipment Manufacturer, pallet nailing tables are specialized machines used in the construction of wooden pallets. These machines automate the nailing process, significantly reducing the time and labor required compared to manual methods. The design of these tables allows for high-speed production while maintaining consistency in quality. They cater to the diverse needs of companies specializing in logistics, warehousing, and manufacturing, ensuring that pallets meet the required industry standards.

Features of OEM Pallet Nailing Tables

One of the standout features of OEM pallet nailing tables is their robust construction. Made with durable materials, they can withstand the repetitive stress and strain of heavy-duty operations. These tables often come equipped with advanced technological integrations, such as programmable logic controllers (PLCs) that allow for precise control of the nailing process. Some models also feature adjustable height and orientation, accommodating different pallet sizes and designs.

Additionally, many OEM pallet nailing tables offer flexibility in terms of nailing patterns and configurations. This versatility allows manufacturers to produce a variety of pallet designs suited for specific applications, whether it's heavy-duty pallets for industrial use or lightweight ones for retail settings.

Benefits of Using OEM Pallet Nailing Tables

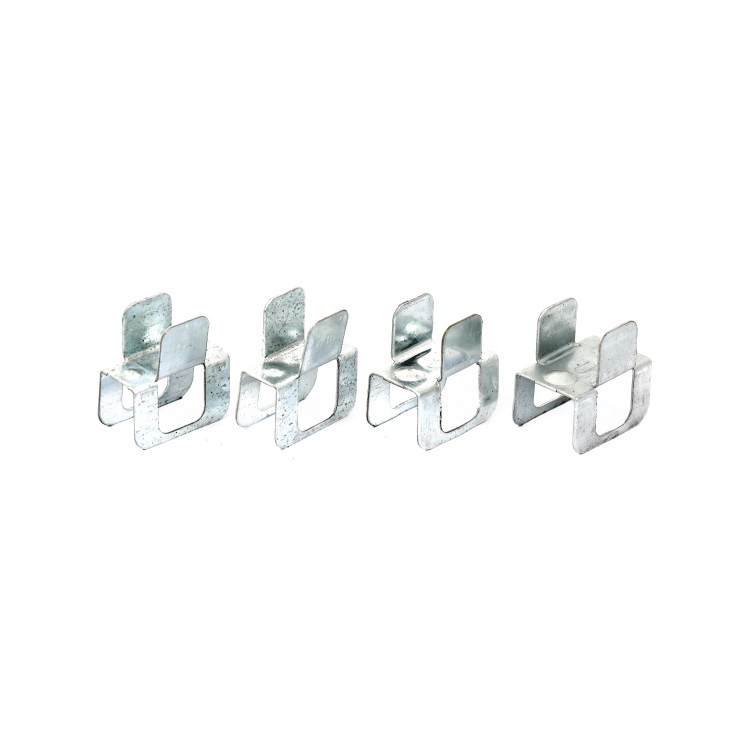

oem pallet nailing table

1. Increased Efficiency By automating the nailing process, OEM pallet nailing tables significantly reduce production time. This allows companies to meet high demand with shorter lead times, which is essential in our fast-paced market.

2. Consistency and Quality Precision is crucial in pallet production. These tables ensure that each nail is placed accurately, minimizing defects and ensuring that the final product adheres to quality standards. This consistency leads to improved reliability for businesses that depend on pallets for transporting goods.

3. Cost-Effectiveness While the initial investment in an OEM pallet nailing table may be substantial, the long-term savings are considerable. Reduced labor costs, lower material waste, and increased production output contribute to a favorable return on investment.

4. Safety Improvements Automating the nailing process also enhances workplace safety. By minimizing manual handling and reducing the risk of injury associated with traditional nailing practices, employers can create a safer working environment for their staff.

5. Sustainability With the growing emphasis on environmentally friendly practices, OEM pallet nailing tables can help optimize the use of resources. Efficient material utilization and reduced waste during production align with sustainability goals, making these machines a greener choice for manufacturers.

Conclusion

In conclusion, OEM pallet nailing tables play a critical role in the efficiency and quality of pallet production. Their advanced features and numerous benefits make them an essential asset for businesses looking to enhance their manufacturing processes. As industries continue to strive for greater efficiency and sustainability, investing in OEM pallet nailing tables will undoubtedly become a wise decision for companies aiming to remain competitive in the global market. By automating and optimizing pallet production, manufacturers can not only meet the demands of today but also prepare for the challenges of tomorrow.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025