OEM Galvanized Wire 4mm Durable and Versatile for Various Applications

Understanding OEM Galvanized Wire A Comprehensive Overview

In the realm of manufacturing and construction, materials play a crucial role in ensuring the stability and longevity of structures. One such essential material is galvanized wire, particularly in the 4mm diameter range, which has become the go-to choice for various applications due to its durability and resistance to corrosion. In this article, we will explore the characteristics, applications, and advantages of OEM (Original Equipment Manufacturer) galvanized wire, focusing specifically on the 4mm variant.

What is OEM Galvanized Wire?

OEM galvanized wire is a type of wire that is produced under the specifications and branding of a company that does not necessarily manufacture the wire itself. Instead, these companies outsource the production to manufacturers who specialize in making galvanized wire. Galvanized refers to a process where steel wire is coated with a layer of zinc to protect it from rust and corrosion. This coating significantly extends the lifespan of the wire, making it suitable for both indoor and outdoor applications.

Characteristics of 4mm Galvanized Wire

The 4mm diameter galvanized wire is particularly suitable for heavy-duty applications. Its thickness provides enhanced tensile strength, enabling it to withstand considerable tension and pressure. The galvanizing process not only protects the wire from environmental factors but also gives it a smooth finish, reducing wear during handling and usage.

One of the remarkable features of 4mm galvanized wire is its resilience against various weather conditions. Whether exposed to rain, humidity, or harsh sunlight, the zinc coating keeps the underlying steel intact, preventing premature deterioration. This makes it an ideal choice for agricultural, industrial, and construction purposes, where exposure to the elements is frequent.

Applications of 4mm Galvanized Wire

The applications of OEM galvanized wire, especially the 4mm variant, are diverse. Here are some prominent uses

1. Fencing The wire is widely used in creating strong and durable fences for agricultural fields, construction sites, and residential properties. Its robust nature ensures that it can withstand the pressure from livestock or natural elements, thus providing security.

2. Construction In building projects, 4mm galvanized wire is commonly employed as reinforcement for concrete structures and as a component in scaffolding systems. Its strength and corrosion resistance make it a reliable choice for structural integrity.

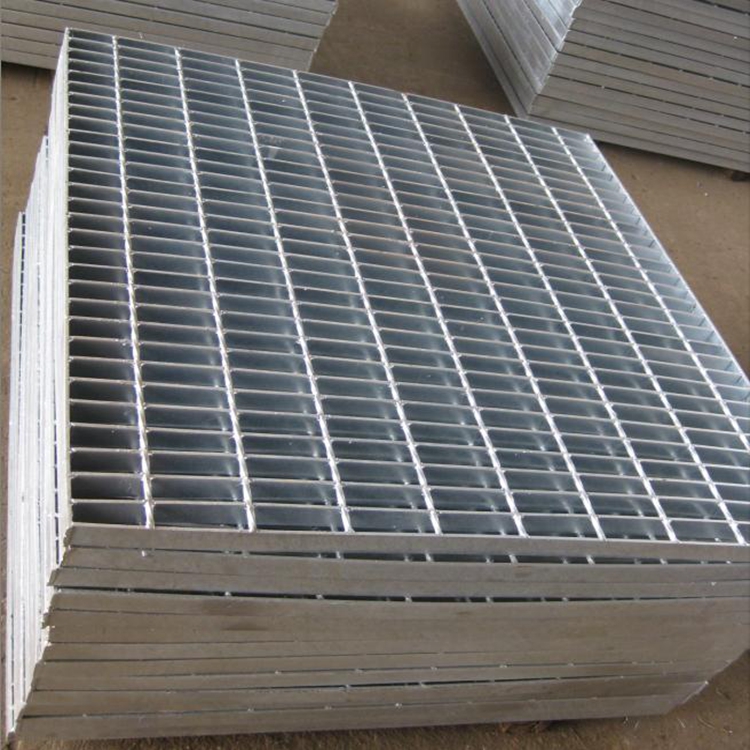

oem galvanized wire 4mm

3. Cable Ties and Fasteners The wire is also utilized to manufacture various fasteners and cable ties essential for wiring and electrical installations. Its ability to endure mechanical stress makes it an ideal material for these applications.

4. Crafting and Art Projects Artists and crafters often prefer using galvanized wire for their projects due to its flexibility and strength. The 4mm diameter wire allows for a range of creative applications, from sculptures to frameworks for other artistic endeavors.

5. Agricultural Uses Farmers frequently use this wire for trellising plants, securely tying down plants, and creating enclosures for crops. Its resistance to rust ensures that it remains functional for extended periods in outdoor settings.

Advantages of Choosing OEM Galvanized Wire

Opting for OEM galvanized wire, especially in the 4mm diameter, comes with several benefits

- Cost-Effectiveness By sourcing wire from manufacturers who can produce at scale, companies often find a more competitive price point, optimizing their project budgets.

- Customization OEM manufacturers can often customize wire based on specific requirements, including different lengths, coatings, and tensile strengths.

- Quality Assurance Established OEMs often ensure strict quality control measures are in place, delivering products that meet industry standards.

- Sustainability Galvanized wire can be recycled, making it a more sustainable option compared to other materials. This aligns with modern construction and manufacturing demands for eco-friendly practices.

Conclusion

OEM galvanized wire, particularly in the 4mm size, stands out as a vital material in various industries. Its strength, durability, and resistance to corrosion ensure it is a reliable choice for both everyday and specialized applications. As the demand for high-quality materials continues to grow, so too does the popularity of galvanized wire—an essential component of modern manufacturing and construction practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025