Custom OEM Nails for Various Applications and Solutions in the Beauty Industry

Understanding OEM Common Nails A Comprehensive Guide

In the world of construction and manufacturing, nails play a crucial role in holding structures together. Among various types of nails, common nails are widely used due to their versatility and strength. This article delves into the concept of OEM (Original Equipment Manufacturer) common nails, exploring their characteristics, benefits, and applications in different industries.

What Are Common Nails?

Common nails are large, sturdy fasteners designed specifically for construction applications, especially for framing and heavy-duty tasks. They usually have a thicker shank compared to other types of nails, such as finishing nails or brads. This thickness ensures they can withstand significant loads, making them ideal for building wooden structures, securing roof sheathing, and more.

Common nails come in various lengths and gauges, which refer to their diameter. The most common sizes range from 1.5 inches to 6 inches in length, with the standard gauge being between 8 and 16. The choice of size and gauge typically depends on the specific application and the materials being used.

The Role of OEM in the Production of Common Nails

OEM stands for Original Equipment Manufacturer. In the context of common nails, an OEM company produces nails according to the specifications and branding of another company. This means that a well-known brand can offer its customers high-quality nails that are manufactured by a different entity.

OEM common nails are designed to meet industry standards, ensuring durability and performance. Manufacturers often utilize advanced technology and quality materials in creating these fasteners. By leveraging OEM services, companies can expand their product lines without the need for significant investment in production facilities.

Advantages of Using OEM Common Nails

1. Quality Assurance OEM manufacturers often adhere to rigorous quality control processes. This ensures that the common nails produced are of high quality and can withstand the demands of construction.

2. Cost-Effectiveness Partnering with an OEM can reduce production costs for companies, as they can benefit from economies of scale. This can lead to more competitive pricing for end consumers.

oem common nails fuzhi

3. Customization Many OEM manufacturers offer the option to customize nails based on specific needs, such as unique lengths or finishes. This allows companies to provide tailored solutions for their clients.

4. Focus on Core Business By outsourcing nail production to OEM manufacturers, companies can concentrate on their core competencies, such as marketing and sales, while leaving manufacturing to experts in the field.

Applications of OEM Common Nails

OEM common nails find application in various sectors, including

- Construction They are essential in residential and commercial building projects for framing, roofing, and securing structures.

- Furniture Manufacturing Common nails are often used to assemble wooden furniture pieces, providing strength and durability.

- Packaging In the packaging industry, common nails are utilized to secure pallets and crates, ensuring that products remain intact during transportation.

- DIY Projects Home improvement enthusiasts and DIYers heavily rely on common nails for a variety of projects, from building decks to crafting shelves.

Conclusion

In summary, OEM common nails represent a significant component of the construction and manufacturing industries. Their strength, versatility, and durability make them a preferred choice for various applications. With the backing of OEM manufacturers, companies can ensure that they provide high-quality products that meet the needs of their customers while maintaining cost-efficiency.

As the demand for reliable fastening solutions continues to grow, understanding the value of OEM common nails will be essential for both businesses and consumers alike. Whether you are a builder, furniture maker, or DIY enthusiast, the importance of selecting the right type of nail cannot be understated. Investing in quality OEM products ensures that your projects will stand the test of time.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

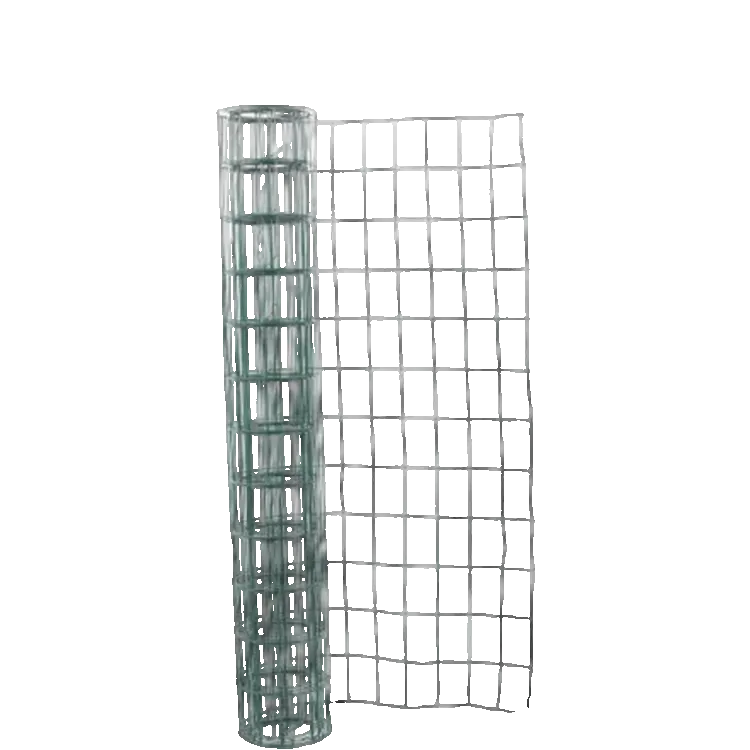

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025