Leading Manufacturer and Supplier of High-Quality Common Nails for Various Construction Needs

Common Nail Manufacturer and Supplier Insights

When it comes to construction, carpentry, and various DIY projects, nails are essential fastening components. Among the myriad types of nails available, common nails hold a special place due to their versatility and widespread use. They are a staple for both professional contractors and home enthusiasts alike. This article delves into the significance of common nail manufacturers and suppliers, exploring their roles in the industry, the production process, and key considerations when choosing a supplier.

Understanding Common Nails

Common nails, typically characterized by their thick shank, flat head, and long length, are favored for their strength and holding power. They are primarily used in framing, general construction, and applications where a robust connection is required. Available in different diameters and lengths, common nails can be made from various materials such as steel, galvanized steel, and stainless steel. The choice of material often depends on the intended application, as factors like resistance to rust and corrosion are crucial in outdoor settings or humid environments.

The Role of Manufacturers

Common nail manufacturers play a pivotal role in ensuring the availability and quality of these essential fastening tools. The manufacturing process involves several stages, including raw material selection, forging, heat treatment, and fine finishing. High-quality common nails are typically made from high-carbon steel, which provides the necessary strength and durability. The manufacturing process must adhere to stringent quality standards to ensure that the nails can withstand the intended loads and environmental factors.

Moreover, advancements in technology have enabled manufacturers to improve production efficiency and product quality. Automated machinery and computer-controlled processes have minimized production errors and enhanced the consistency of dimensions, strength, and coating. This technological evolution not only meets market demands but also opens doors for customizations tailored to specific requirements.

common nail manufactruer supplier

Key Considerations for Suppliers

When selecting a common nail supplier, several factors come into play. The first consideration is the range of products available. A reliable supplier should offer a diverse selection of common nails in various sizes and materials to cater to different needs. Additionally, the consistency of supply is crucial; a dependable supplier should have a robust inventory and a streamlined logistics system to ensure timely delivery.

Quality assurance is another critical aspect. Suppliers should be able to provide certifications or documentation of quality standards, such as ISO certifications, indicating that their products meet industry benchmarks. It is advisable to check customer reviews and testimonials to gauge the supplier's reputation and reliability.

Pricing is, of course, an essential consideration; however, it is vital to balance cost with quality. The cheapest option may not always deliver the best results, leading to potential issues in construction or repairs down the line. Engaging with suppliers who emphasize value for money through durable products can provide long-term savings and enhance project outcomes.

Conclusion

In summary, common nail manufacturers and suppliers play a crucial role in the construction and DIY sectors. Understanding the importance of the manufacturing process, the diverse applications of common nails, and the criteria for selecting a reliable supplier is essential for anyone involved in carpentry or construction projects. By prioritizing quality, range, and reliable service, stakeholders can ensure that they are equipped with the right tools for their endeavors, resulting in strong, lasting results in their work. Whether for a small home project or a large-scale construction job, choosing the right common nail supplier can lead to successful and satisfactory outcomes.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

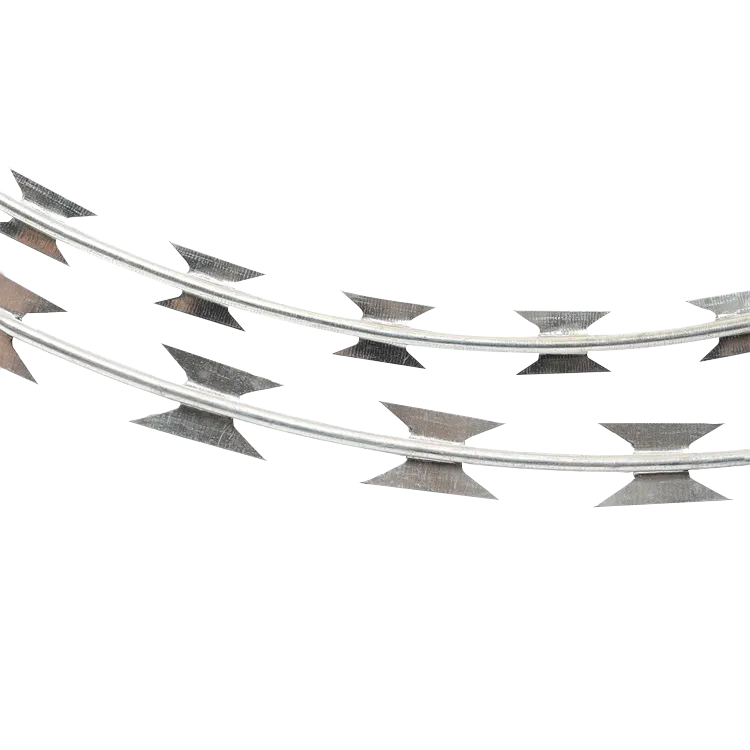

Enhance Your Security with Razor Wire

NewsJun.26,2025