Leading Manufacturers of Galvanized Wire in Various BWG Sizes for Diverse Applications

Understanding Galvanized Wire and Its Manufacturers A Comprehensive Overview

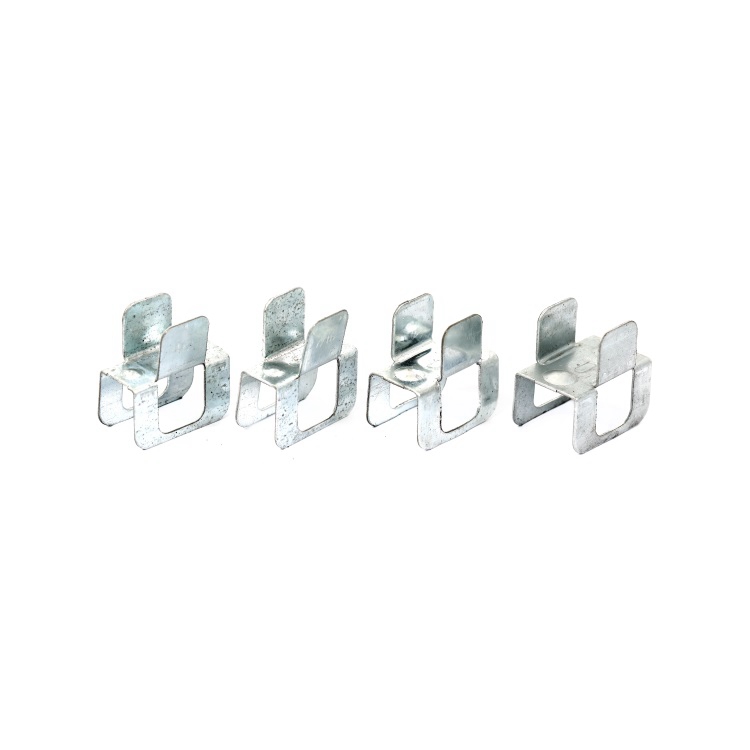

Galvanized wire, recognized for its durability and resistance to corrosion, plays a vital role in various industries and applications. The manufacturing process involves coating steel wire with a layer of zinc, which significantly enhances its longevity and performance. This article delves into the key aspects of galvanized wire, particularly focusing on its dimensions, the Wire Gauge (BWG) system, and notable manufacturers.

What is Galvanized Wire?

Galvanized wire is produced through a process known as galvanization, where iron or steel is coated with zinc to protect it from rust. This protective layer is crucial, especially in environments where the wire is exposed to moisture, chemicals, and extreme weather conditions. Galvanized wire can be used in a variety of applications, including fencing, construction, agriculture, and crafting. It is favored for its strength, flexibility, and ability to withstand harsh conditions.

Understanding Wire Gauge (BWG)

The standard measurement for wire thickness is known as the wire gauge (BWG - Birmingham Wire Gauge). This system is essential for determining the appropriate size of the wire for specific applications. The lower the gauge number, the thicker the wire. For instance, a 10 BWG wire is thicker than a 20 BWG wire. The thickness of the wire directly influences its tensile strength, flexibility, and overall utility in various applications. For instance, fencing and construction often require thicker wires, while craft projects may utilize thinner gauges.

Key Applications of Galvanized Wire

1. Fencing One of the most common uses for galvanized wire is in the construction of fencing. It provides a strong, durable barrier against animals and intruders while remaining economically viable.

2. Construction In the construction industry, galvanized wire is employed in mesh and reinforcement applications. Its resistance to rust makes it ideal for concrete reinforcement and various structural supports.

galvanized wire bwg manufacturers

4. Crafting and DIY Projects Many crafters and DIY enthusiasts appreciate galvanized wire for its aesthetic appeal and functional properties, making it a popular choice for creating unique sculptures, jewelry, and home décor.

Choosing the Right Manufacturer

Selecting a reputable manufacturer is crucial when sourcing galvanized wire. The market offers various manufacturers, each with unique strengths and product lines. Here are a few key considerations

- Quality Certifications Look for manufacturers that comply with international standards and have quality certifications. This ensures that the wire produced is of high quality and meets safety requirements.

- Product Range Consider manufacturers that offer a wide range of wire gauges and types. This flexibility allows customers to source the exact products they need for specific applications.

- Reputation and Experience Established manufacturers with a strong reputation often provide reliable and consistent products. Researching customer reviews and testimonials can offer insights into their reliability and service quality.

- Pricing and Value While cost is an important factor, it should not be the sole criterion. Evaluate the overall value, including quality, service, and delivery times, in addition to price.

Conclusion

Galvanized wire remains an integral component across various industries due to its versatility, strength, and resistance to corrosion. The detailed understanding of wire gauges and awareness of reputable manufacturers are essential for consumers and businesses alike. By considering these factors, one can make informed decisions that enhance the effectiveness of their projects while ensuring quality and durability. Whether for fencing, construction, agriculture, or crafting, galvanized wire serves as a reliable choice in the ever-evolving landscape of material applications.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025