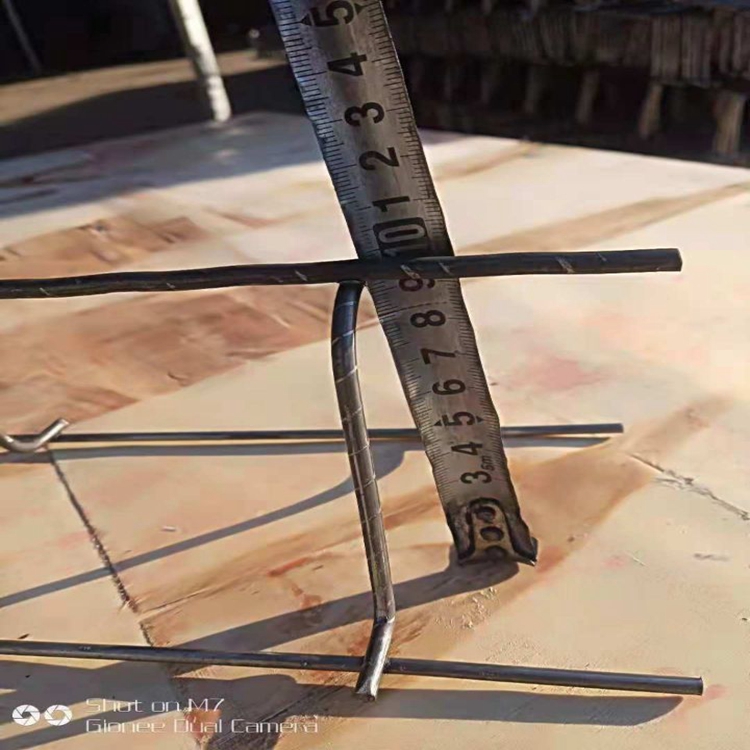

galvanized wire 6mm factory

Exploring the World of 6mm Galvanized Wire A Factory Perspective

In today's industrial landscape, galvanized wire plays a crucial role in a myriad of applications, ranging from construction to agriculture. Among the various sizes available, 6mm galvanized wire stands out due to its strength and versatility. As manufacturers focused on producing high-quality materials, the process and characteristics of 6mm galvanized wire become paramount. This article delves into the processes involved in manufacturing this wire, its applications, and the advantages it offers.

Manufacturing Process

The production of 6mm galvanized wire begins with the selection of high-quality steel. Steel wire rods are drawn through a series of dies to achieve the desired 6mm diameter. This process, known as wire drawing, enhances the tensile strength of the wire while providing a smooth surface finish. Once the wire achieves the specified diameter, it is cleaned to remove any impurities and prepare it for galvanization.

Galvanization is a critical step in the manufacturing process that involves coating the steel wire with a layer of zinc. This is typically done through a process known as hot-dip galvanization, where the wire is immersed in molten zinc. The resulting zinc coating serves as a barrier against corrosion, significantly extending the lifespan of the wire when exposed to various environmental conditions. The thickness of the zinc coating can be adjusted based on specific requirements, ensuring optimal durability.

After galvanization, the wire undergoes several quality checks to ensure that it meets industry standards. These tests assess factors such as tensile strength, elongation, and the integrity of the zinc coating. Only after passing these rigorous quality assessments does the wire reach the packaging stage, ready to be shipped out to customers and industries.

Applications

galvanized wire 6mm factory

The applications of 6mm galvanized wire are extensive. In construction, it is widely used for reinforcing concrete and providing structural support. Its strength and resistance to rust make it ideal for use in scaffolding and fencing. Additionally, the agricultural sector utilizes galvanized wire for fencing livestock, creating trellises for climbing plants, and even for supporting shade structures in agricultural settings.

Furthermore, in industries like manufacturing and shipping, this wire is employed for bundling products, creating cages, and securing various loads. The versatility of 6mm galvanized wire makes it a preferred choice in numerous sectors, thanks to its robust characteristics and adaptability.

Benefits of 6mm Galvanized Wire

One of the primary advantages of using 6mm galvanized wire is its exceptional resistance to corrosion. The zinc coating protects the steel from moisture and various environmental elements, ensuring longevity. This corrosion resistance translates into reduced maintenance costs and increased reliability for users.

Additionally, the strong tensile strength of 6mm galvanized wire allows it to withstand significant loads without deformation, making it suitable for heavy-duty applications. Its flexibility also enables various configurations, making it a versatile option for different projects.

In conclusion, the production of 6mm galvanized wire is a meticulous process that ensures a high-quality end product. With its wide range of applications and numerous benefits, this wire serves as an indispensable resource across many industries. As demands continue to evolve, manufacturers must remain committed to innovation and quality, ensuring that galvanized wire meets the needs of the modern world.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025