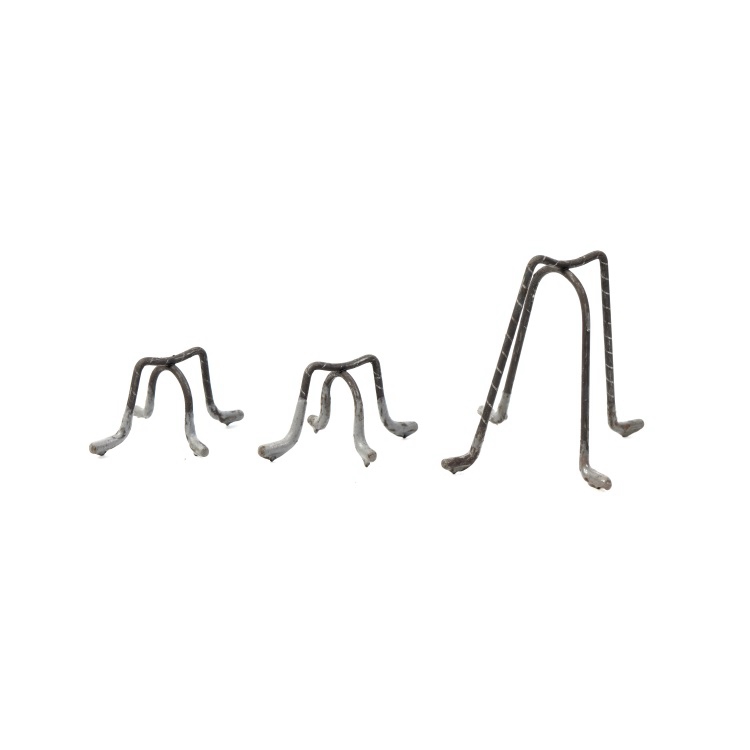

galvanized metal wires manufacturer

The Role of Galvanized Metal Wires in Modern Manufacturing

Galvanized metal wires have become an essential component in various industries, serving a wide range of applications including construction, agriculture, and manufacturing. The process of galvanization involves coating steel wires with a layer of zinc to prevent rust and corrosion, which significantly extends their lifespan and versatility. This article delves into the manufacturing of galvanized metal wires, exploring their applications, benefits, and the market landscape.

Manufacturing Process

The production of galvanized metal wires begins with the selection of high-quality steel. The steel is drawn into wire form, often undergoing several stages to attain the desired diameter and tensile strength. This drawing process is crucial, as the properties of the wire will determine its effectiveness in various applications.

Once the wires are prepared, they are subjected to the galvanization process. There are two primary methods for galvanization hot-dip galvanization and electro-galvanization. In hot-dip galvanization, the steel wires are immersed in molten zinc, allowing the zinc to bond with the surface of the steel, creating a robust protective layer. This method is highly effective and results in a thicker coating compared to electro-galvanization, which involves applying a thin layer of zinc through an electrochemical process.

The choice of galvanization method often depends on the intended use of the wire. Hot-dip galvanized wires are preferred for outdoor applications where exposure to moisture and corrosive elements is prevalent, such as in fencing, bridges, and construction scaffolding.

Applications of Galvanized Metal Wires

Galvanized metal wires are widely used across various sectors. In the construction industry, they are employed for reinforcing concrete structures, creating barbed wire for security fencing, and in wire mesh applications. Their strength and corrosion resistance make them ideal for environments where durability is critical.

In the agricultural sector, galvanized wire is commonly used for livestock fencing, trellises for climbing plants, and support structures for crops

. The resistance to rust ensures that farms can rely on this material for years, thereby reducing replacement costs and maintenance.galvanized metal wires manufacturer

The manufacturing sector also utilizes galvanized metal wires in the production of various goods. They are essential components in the automotive industry, where they are used in wiring harnesses and other applications that require reliable strength and protection against environmental degradation.

Benefits of Galvanized Wires

The advantages of galvanized metal wires are numerous. The primary benefit is their longevity; by preventing rust and corrosion, galvanized wires can last much longer than non-galvanized options. This durability translates to lower maintenance costs and increased safety in applications where structural integrity is paramount.

Moreover, galvanized wires are highly versatile. They can be fabricated into different shapes and sizes to meet specific needs, making them suitable for a broad range of applications. These wires also maintain their structural properties under various environmental conditions, adding to their reliability.

Another significant advantage is the low cost of galvanized wires compared to other materials. The galvanization process is relatively economical, allowing manufacturers to offer competitive prices without sacrificing quality.

Market Landscape

As industries continue to grow, the demand for galvanized metal wires is projected to increase. With the ongoing focus on infrastructure development and agricultural innovations, manufacturers are optimistic about the market's future. Companies specializing in galvanized metal wire production are investing in advanced technologies and sustainable practices to enhance their product offerings and minimize environmental impact.

In conclusion, galvanized metal wires are a staple in many industries due to their exceptional strength, durability, and cost-effectiveness. As manufacturers continue to innovate and improve galvanization processes, the role of galvanized wires will only become more vital in meeting the demands of modern applications. Whether in construction, agriculture, or manufacturing, these wires remain an integral part of the infrastructure that supports our daily lives.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025