What Is Annealed Wire?

Annealed wire is steel wire that has undergone a heating and cooling treatment to change its chemical and physical properties. To make this kind of wire, manufacturers heat a low-carbon steel wire to a specific temperature. Then, they cool it at a specific rate to prevent cracking within the steel. Many manufacturers then coat the annealed wire with oil to make it easier to operate through machinery.

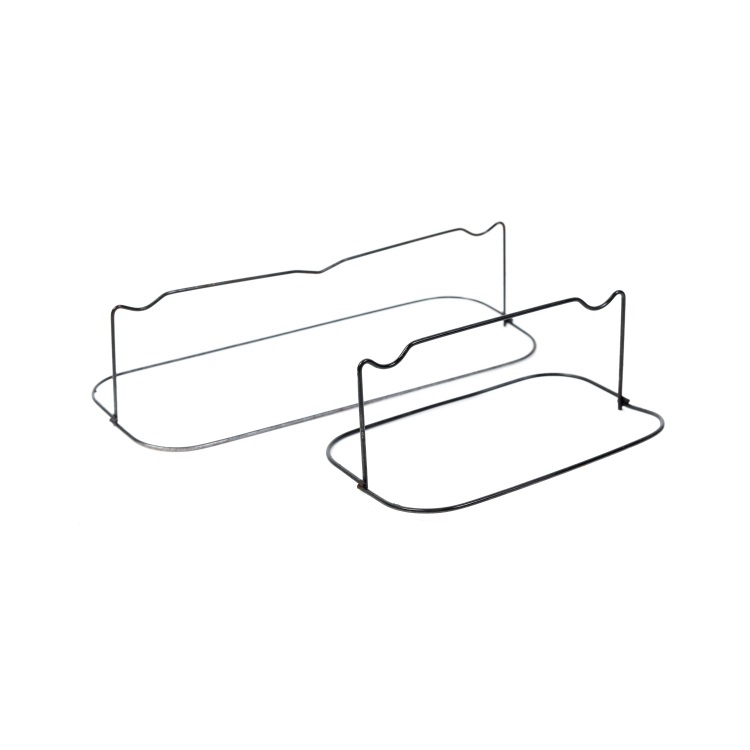

The most significant advantage of annealed steel wire is that it is more pliable than regular steel wire. The manufacturing process reduces annealed wire's rigidity, giving it more flexibility than pure steel. These properties make annealed wire ideal for situations requiring strength and flexibility.