High-Quality Galvanized Anchor Bolts Manufacturer | Durable & Reliable Solutions

Galvanized Anchor Bolt Factory Ensuring Strength and Durability

In the world of construction and structural engineering, the importance of strong, durable anchoring systems cannot be overstated. Among the various anchors used, galvanized anchor bolts stand out due to their exceptional corrosion resistance and robust structural integrity. A galvanized anchor bolt factory specializes in the production of these essential components, catering to the needs of various industries, including construction, marine, and infrastructure.

Galvanization is a process that involves coating steel with a layer of zinc to prevent rust and corrosion. This protective layer is critical, especially when anchor bolts are exposed to harsh environmental conditions. The galvanized anchor bolt factory utilizes advanced techniques to ensure that every bolt produced meets rigorous quality standards. The manufacturing process involves several stages from the selection of high-quality steel raw materials to the hot-dip galvanization process, and finally, to stringent quality control measures.

At the heart of any reputable galvanized anchor bolt factory is a commitment to quality and innovation. Factories invest in state-of-the-art machinery and employ skilled technicians who understand the nuances of metallurgy and coating processes. This expertise ensures that the anchor bolts produced are not only strong but also have a long lifespan, which is vital for the structural integrity of buildings and infrastructure.

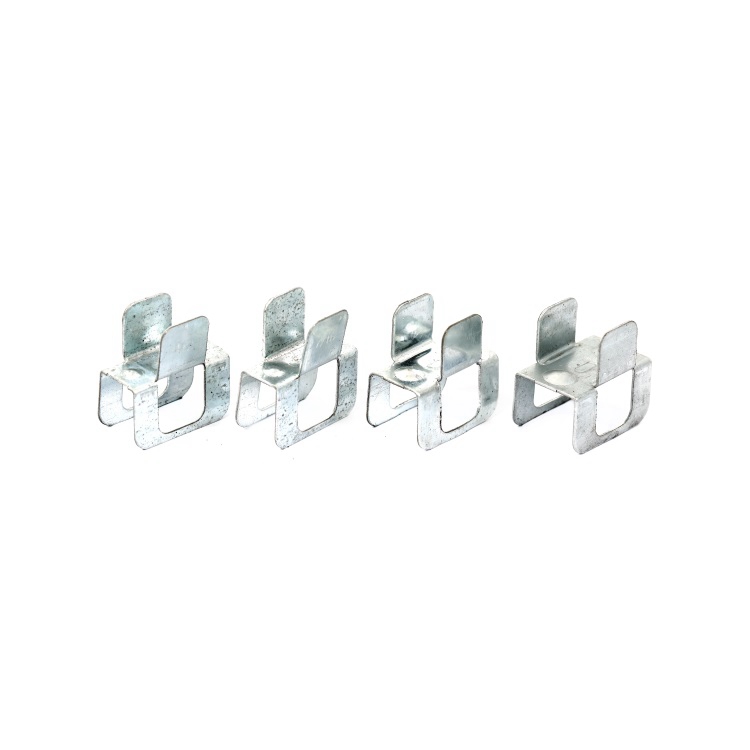

galvanized anchor bolt factory

The applications of galvanized anchor bolts are diverse. They are commonly used in foundations to secure structures to the ground, in bridges to connect various components, and in marine applications where exposure to water can accelerate corrosion. The versatility of galvanized anchor bolts makes them a preferred choice among engineers and contractors who need reliable solutions for securing heavy materials.

Moreover, the environmental benefits of using galvanized anchor bolts should not be overlooked. By increasing the lifespan of structures, these bolts contribute to sustainability by reducing the need for replacements and minimizing waste. The galvanization process itself is designed to be eco-friendly, using materials and methods that limit environmental impact.

In an increasingly competitive market, a galvanized anchor bolt factory differentiates itself through exceptional customer service and customization options. Clients can choose from various sizes, shapes, and specifications, allowing for tailored solutions that meet specific project requirements. This flexibility, combined with reliable delivery and competitive pricing, positions galvanized anchor bolt factories as essential partners in the construction process.

In conclusion, a galvanized anchor bolt factory plays a crucial role in the construction industry by providing high-quality, durable anchoring solutions. The combination of advanced manufacturing techniques, a commitment to quality, and an understanding of customer needs ensures that galvanized anchor bolts continue to be an indispensable element in building safe and resilient structures. As the demand for sustainable and long-lasting construction solutions grows, the role of these factories will only become more significant in the years to come.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025