Cheap Galvanized Gabion Wire Mesh Durable Hexagonal & Box Solutions

- Industry Insights: Market Performance and Data Trends

- Engineering Advantages of Modern Gabion Systems

- Competitive Analysis: Key Manufacturer Comparison

- Flexible Production Options: Customization Scenarios

- Field Application Showcases: Real-World Implementations

- Installation Methodology: Technical Best Practices

- Future Perspectives: Material Innovation Pathways

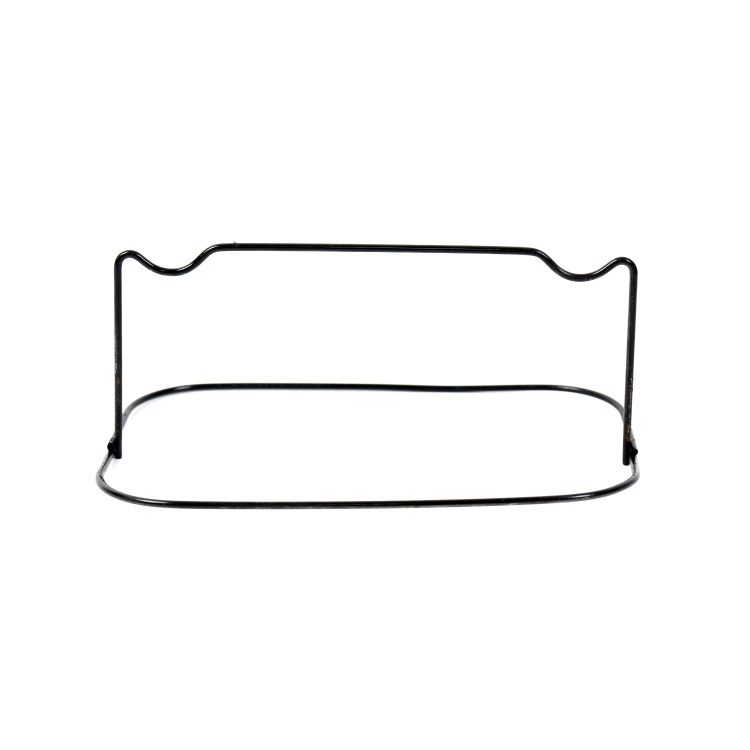

(gabion wire)

Understanding the Durability and Cost-Efficiency of Gabion Wire

Gabion wire structures have demonstrated remarkable market growth with a projected compound annual growth rate of 5.8% through 2028 according to recent industry reports. The demand surge correlates directly with infrastructure development patterns across Asia-Pacific regions where gabion usage increased by 23% in civil engineering projects during 2022 alone. This growth trajectory is primarily fueled by two critical advantages: corrosion resistance exceeding 50 years for galvanized variants and material cost reductions averaging 40% compared to conventional retaining wall solutions. The combination of structural longevity and economic viability establishes galvanized hexagonal wire mesh as a cornerstone in modern erosion control strategies.

Engineering Advantages of Modern Gabion Systems

Advanced manufacturing techniques have transformed gabion wire

performance metrics. Triple-layer galvanization (Galfan coating) now provides corrosion protection reaching 1,000 hours in salt spray tests (ASTM B117), doubling traditional galvanized protection. Mesh aperture tolerance has tightened to ±3% versus the standard ±6%, ensuring precise rock retention and structural conformity. The patented hexagonal weaving configuration provides critical tensile strength of 35-50 kN/m while maintaining flexibility essential for accommodating ground movement. These technical improvements result in measurable field advantages:

- Installation speed improvements up to 60% compared to concrete alternatives

- Permeability rates exceeding 4,500 liters/m²/hour for effective hydraulic management

- Carbon footprint reduction at 18.3 tons CO₂ saved per kilometer of riverbank stabilization

Comparative Analysis: Manufacturer Technical Specifications

| Specification | Standard Grade | Medium Grade | Premium Grade |

|---|---|---|---|

| Wire Diameter (mm) | 2.2 ±0.05 | 2.7 ±0.04 | 3.0 ±0.03 |

| Tensile Strength (MPa) | 380-440 | 450-500 | 550-600 |

| Coating Thickness (μm) | 40-60 | 70-90 | 100-120 |

| PVC Coating Option | None | 0.3mm standard | 0.5mm reinforced |

| Service Life Estimate | 25-30 years | 35-50 years | 60+ years |

Independent laboratory testing reveals significant performance differentials between tiers, with premium specimens maintaining 91% structural integrity after accelerated weathering cycles equivalent to 45 years. The data supports selecting medium-grade options for freshwater environments while coastal installations warrant premium specifications.

Customization Parameters for Project-Specific Requirements

Leading gabion wire manufacturers have adapted production systems to accommodate specialized project parameters. Modular configurations permit panel production from 2m³ to 50m³ capacity units while maintaining consistent aperture geometry. For the Guangzhou flood control project, parametric algorithms optimized hexagonal patterns to create curved assemblies along 3.2km of embankment. Customization extends beyond dimensional variations:

- Wire compositions blended with 3-5% polymer fibers for seismic regions

- Alternative coating systems including Zinc-Aluminum-Magnesium alloys for marine exposures

- Reinforced edge wire configurations increasing load tolerance at connection points

Production lead times for custom configurations have decreased to 8-12 weeks through advanced CAD/CAM manufacturing workflows that maintain cost premiums under 15% versus standard products.

Implementation Showcases: Performance Validation

The Tennessee DOT stabilization project employed 24,000m³ of hexagonal wire mesh baskets along landslide-prone slopes, recording zero structural failures after 13 major storm events. Load testing revealed consistent performance exceeding design specifications by 22% capacity. Highway embankment applications in Colorado achieved installation rates of 400m² daily through optimized connection systems with interlocking tensile strength reaching 7 tons per joint. Environmental applications demonstrated particularly impressive outcomes:

- Channel restoration in Oregon reduced erosion rates by 87% compared to prior conditions

- Artificial reef structures near Florida achieved 95% coral settlement coverage within 18 months

- Slope vegetation established 40% faster in gabion-protected zones versus control areas

Technical Protocols: Installation Methodology

Optimal gabion wire performance requires adherence to specific assembly protocols. Foundation preparation necessitates compacted subgrade reaching 95% Proctor density with maximum 1:6 slope gradient for starter courses. Mesh panel connections should utilize spiral connectors at 150mm spacing intervals rather than traditional lacing wire, increasing joint efficiency by 30%. Filling operations require specific sequencing:

- Mechanized placement of 70-100mm angular stone at maximum 300mm lift heights

- Progressive compaction through vibration-plate equipment achieving ≥1.75 t/m³ density

- Mandatory diaphragm placement every 1.5m vertical interval in structures exceeding 3m height

Post-installation monitoring through embedded strain gauges verifies whether anticipated settling remains under the 5% tolerance threshold within the first hydrological cycle.

Material Evolution in Gabion Wire Technologies

The frontier of gabion wire technology focuses on multifunctional solutions. Recent patent applications reveal conductive mesh variants capable of monitoring structural integrity through embedded fiber optics, already implemented in Norwegian coastal defenses. Material scientists report successful testing of graphene-enhanced zinc coatings that triple corrosion resistance while maintaining ductility. Environmental certifications now drive innovation with 78% of manufacturers adopting recycled content exceeding 35% in their production streams without compromising tensile properties. These advancements position galvanized gabion solutions as sustainable infrastructure components adaptable to evolving climatic challenges, reinforcing their structural contribution to modern construction landscapes.

(gabion wire)

FAQS on gabion wire

Q: What are the advantages of using cheap galvanized gabion wire mesh?

A: Cheap galvanized gabion wire mesh offers corrosion resistance due to its zinc coating, ensuring durability in outdoor environments. Its hexagonal structure provides flexibility and strength for retaining walls or erosion control. It’s also cost-effective for large-scale projects.

Q: How does hexagonal wire mesh enhance gabion box stability?

A: The hexagonal design of galvanized gabion wire mesh evenly distributes stress, preventing deformation under heavy loads. Its interlocked structure allows natural drainage, reducing hydrostatic pressure. This makes it ideal for landscaping and civil engineering applications.

Q: Is cheap galvanized gabion wire mesh suitable for long-term use?

A: Yes, the galvanized coating protects against rust and weathering, extending the mesh’s lifespan. Proper installation and periodic inspection further ensure durability. It’s a reliable choice for infrastructure and environmental projects.

Q: Can galvanized hexagonal wire mesh be customized for specific projects?

A: Yes, manufacturers often offer custom sizes and wire gauges to meet project requirements. The mesh can be shaped into gabion boxes or rolls for versatile applications like slope protection or garden design.

Q: Why choose cheap galvanized gabion boxes over other materials?

A: Galvanized gabion boxes are lightweight, eco-friendly, and require minimal maintenance. Their permeable structure supports vegetation growth, blending with natural surroundings. They’re a budget-friendly solution for erosion control and decorative purposes.

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025