ga 16 gib tie wire factories

The Rise of GA 2016 GIB Tie Wire Factories A Comprehensive Overview

In the ever-evolving landscape of manufacturing, the GA 2016 GIB tie wire factories have emerged as significant players in the industry. This paper delves into the operational framework, technological advancements, market relevance, and environmental considerations surrounding these factories, providing a comprehensive understanding of their impact in the global manufacturing sector.

Operational Framework

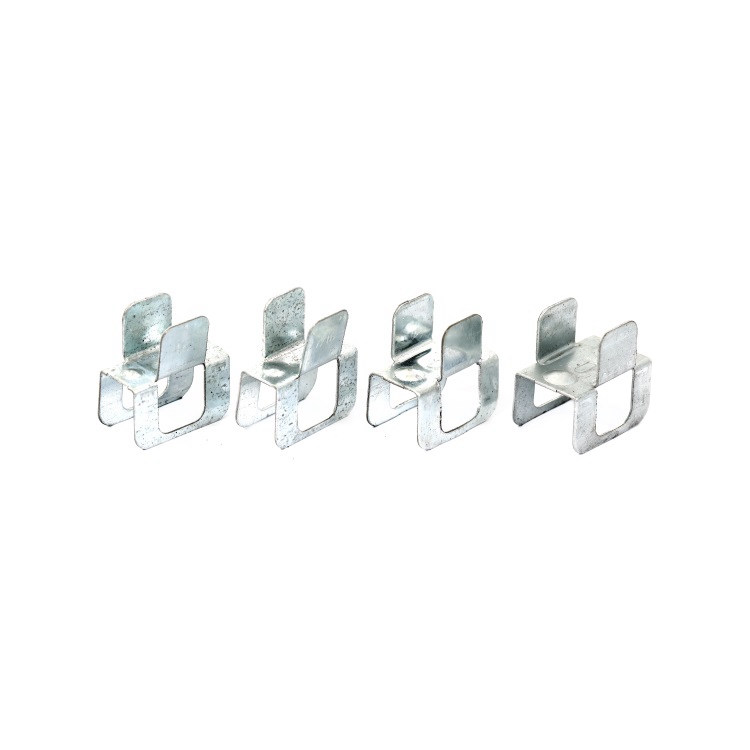

GA 2016 GIB tie wire factories are structured to meet the increasing demand for quality tie wires in various construction and manufacturing applications. Tie wires are essential components utilized primarily in the construction industry for reinforcing concrete structures and securing materials together. The operational framework of these factories is designed to optimize production efficiency while ensuring the highest quality standards.

The manufacturing process typically involves the production of wire from raw materials, followed by drawing, annealing, and galvanizing processes to enhance the wire's durability and resistance to corrosion. Advanced machinery and automated systems facilitate these processes, enabling factories to maintain a consistent output that meets international quality benchmarks.

Technological Advancements

The integration of cutting-edge technology in GA 2016 GIB tie wire factories has been a game-changer. Automation plays a pivotal role in enhancing production speed and accuracy, reducing the likelihood of human error. Additionally, the adoption of Internet of Things (IoT) technologies allows for real-time monitoring and data analytics, enabling factory operators to optimize processes and reduce waste.

Moreover, advancements in material science have led to the development of high-strength tie wires that offer superior performance. These innovations not only improve the structural integrity of constructions but also cater to the growing demands for lightweight and sustainable building materials.

Market Relevance

ga 16 gib tie wire factories

The global tie wire market has witnessed significant growth, driven by booming construction activities worldwide. GA 2016 GIB tie wire factories are strategically positioned to leverage this trend. By focusing on both quality and cost-effectiveness, these factories have attracted a diverse clientele ranging from small-scale contractors to large construction firms.

Furthermore, as countries strive to improve their infrastructure and housing, the demand for reliable tie wires has surged. The factories have responded to this demand by ensuring that their products comply with international standards, making them competitive in the global market.

Environmental Considerations

With the increasing concerns over environmental sustainability, GA 2016 GIB tie wire factories have made concerted efforts to minimize their ecological footprint. Implementing eco-friendly manufacturing processes, such as recycling waste materials and utilizing energy-efficient machines, has become a priority. Additionally, there is a growing emphasis on sourcing raw materials from sustainable suppliers to ensure responsible production practices.

The factories are also investing in research and development to explore alternatives to conventional materials, aiming to reduce the impact of their operations on the environment. By adopting green technologies, they not only contribute to global sustainability efforts but also resonate with the values of environmentally conscious consumers.

Conclusion

In conclusion, GA 2016 GIB tie wire factories represent a critical segment of the manufacturing industry, particularly in the realm of construction supplies. Their operational efficiency, technological advancements, and commitment to sustainability position them as leaders in the tie wire market. As the demand for quality construction materials continues to rise, these factories are well-equipped to meet the challenges ahead.

The future of GA 2016 GIB tie wire factories looks promising, with ongoing investments in technology and sustainability ensuring that they remain competitive. As the industry evolves, these factories are likely to play an even more significant role in shaping the standards of quality and innovation in the tie wire manufacturing sector.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025