Understanding the Costs of Custom GI Wire per Kilogram

Understanding Custom GI Wire Prices per Kilogram

The market for galvanized iron (GI) wire is diverse and dynamic, catering to various industries such as construction, agriculture, manufacturing, and more. The price of custom GI wire per kilogram is influenced by a multitude of factors, ranging from raw material costs to market demand, and understanding these variables is crucial for businesses and consumers alike. This article delves into the intricacies of GI wire pricing, including its applications, influencing factors, and the current trends in the market.

What is GI Wire?

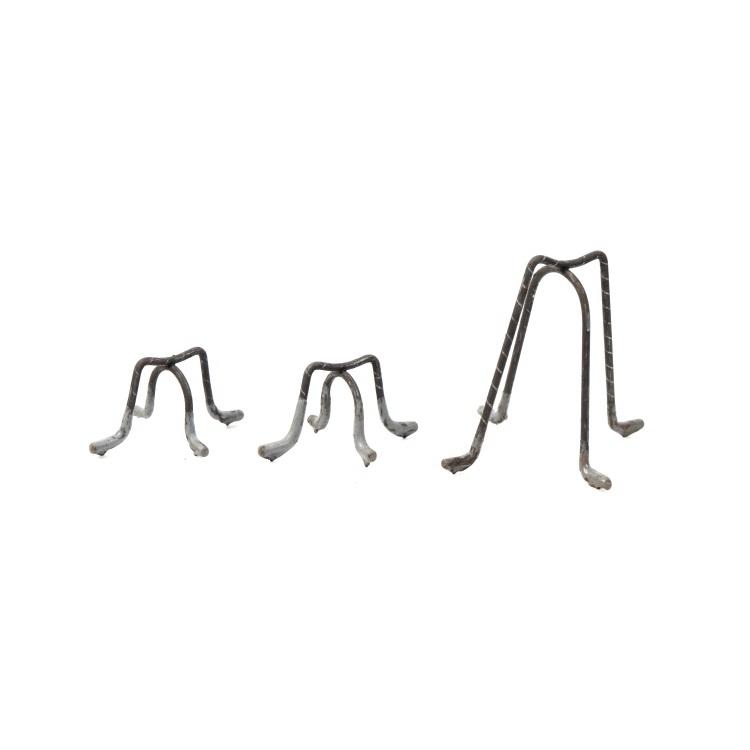

Galvanized iron wire is made from iron that has been coated with a layer of zinc to provide anti-corrosive properties. This makes it ideal for outdoor use and in environments where exposure to moisture is common. GI wire is commonly used for fencing, construction reinforcement, crafting, and various industrial applications. It is known for its strength, durability, and ability to withstand harsh weather conditions, all while maintaining affordability.

Factors Affecting Custom GI Wire Prices

1. Raw Material Costs The primary ingredient in GI wire is iron, and fluctuations in its price can significantly impact the overall price per kilogram. Additionally, the cost of zinc—which is used in the galvanization process—also plays a crucial role. Global mining operations and trade regulations can lead to varying prices for these metals, thus affecting the final cost of GI wire.

2. Production Methods The methods used in producing GI wire can influence its pricing. For instance, custom GI wire that requires specific measurements, thickness, or coating may incur higher production costs. Advanced manufacturing techniques that ensure superior quality or additional features, such as improved corrosion resistance, may also contribute to increased prices.

3. Market Demand and Supply The law of supply and demand is a fundamental economic principle that affects pricing. In periods of high demand, such as during construction booms or agricultural seasons, prices may spike. Conversely, during slow periods, prices might stabilize or even decline. Custom orders that require specific wire dimensions or coatings can also influence the price due to limited supply and increased production complexity.

custom gi wire price per kg

4. Geographical Factors The location of production facilities and the distance to the market also play a role in the pricing. Transportation costs, tariffs, and local economic conditions can lead to variations in price for GI wire across different regions and countries.

5. Quality and Certification Higher quality GI wire that meets international standards or has undergone certain certifications may be priced higher. Customers often seek reliable suppliers who can guarantee the quality of their products, willing to pay a premium for assurance.

Current Market Trends

As of 2023, the GI wire market has shown resilience despite the challenges of global economic shifts and supply chain disruptions. There is a growing trend towards sustainability and environmentally friendly production methods, which can influence pricing structures. Many manufacturers are investing in eco-friendly galvanization processes, leading to an increase in production costs that may be passed on to consumers.

Moreover, the increased use of GI wire in emerging markets for construction and infrastructure development has contributed to a steady demand, potentially driving prices up in the coming years. As industries evolve and adopt innovative technologies, the customization of products like GI wire is likely to gain importance, reinforcing the trend of tailored pricing.

Conclusion

In summary, understanding the price of custom GI wire per kilogram involves a comprehensive analysis of various factors, including raw material costs, production methods, market demand, and geographical influences. As businesses and consumers navigate this dynamic landscape, keeping abreast of market trends and pricing strategies will be essential. By being informed, they can make better purchasing decisions and adapt to the evolving market of galvanized iron wire, ensuring they receive the best value for their investments.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025