Custom Galvanized Wire for Tie Applications and Durable Solutions

The Versatility and Importance of Custom GI Tie Wire

In the construction and manufacturing industries, the significance of reliable fastening materials cannot be overstated. One such essential material is the custom GI (Galvanized Iron) tie wire, a versatile product that plays a crucial role in various applications. Whether in building structures, engineering projects, or crafting artistic designs, custom GI tie wire stands as a pivotal component that contributes to strength and durability.

Understanding GI Tie Wire

Galvanized Iron wire is produced by coating steel wire with a layer of zinc through a process known as galvanization. This protective layer prevents rust and corrosion, making it suitable for outdoor use and in environments subjected to moisture. Custom GI tie wire is typically available in various diameters, lengths, and tensile strengths, allowing for tailored solutions that meet specific project requirements.

Applications of Custom GI Tie Wire

The applications of custom GI tie wire are extensive and can be seen across a spectrum of industries

1. Construction In the realm of construction, GI tie wire is essential for securing materials together during concrete pouring, tying rebar, and securing insulation. The wire holds various components in place, ensuring the stability and integrity of structures during the curing process.

2. Agriculture Farmers utilize GI tie wire for numerous purposes such as fastening fences, trellising plants, and securing various agricultural structures. Its strength and resistance to weathering make it a reliable choice for outdoor applications.

3. Manufacturing In manufacturing, custom GI tie wire is used in the production of different products, including furniture, appliances, and machinery. Its flexibility allows for crafting intricate designs while ensuring durability.

4. Art and Craftwork Artists and artisans often turn to custom GI tie wire for sculptures, installations, and intricate craft projects. The wire can be manipulated easily, allowing for creativity in design while providing structural support.

custom gi tie wire

Benefits of Customization

The ability to customize GI tie wire has significant advantages

- Tailored Solutions Different projects have varying requirements in terms of strength, flexibility, and corrosion resistance. Customization ensures that the tie wire meets the specific needs of each project, which is particularly important in construction and engineering.

- Improved Efficiency By having wire that meets exact specifications, contractors and manufacturers can streamline their processes. Custom GI tie wire minimizes waste and maximizes the effectiveness of materials used.

- Higher Quality Control Custom manufacturers often adhere to stringent quality standards, ensuring that the tie wire meets safety and performance expectations. This aspect is crucial in sectors like construction, where material failure could lead to catastrophic outcomes.

Environmental Considerations

With increasing awareness of environmental issues, the longevity of galvanized iron tie wire is a significant advantage. Its resistance to rust extends the life of projects, reducing the need for frequent replacements. Additionally, the production processes for galvanized wire can incorporate eco-friendly practices, further contributing to sustainability in construction and manufacturing.

Conclusion

Custom GI tie wire stands out as an indispensable material in diverse fields, from construction to agriculture and artistic endeavors. Its durability, adaptability, and resistance to corrosion make it a reliable choice for various applications. The options for customization ensure that it meets unique project specifications, enhancing efficiency and safety. As industries continue to evolve, the demand for high-quality, customized fastening solutions like GI tie wire will remain robust, underscoring its integral role in modern construction practices and beyond. Whether you are building a skyscraper, tending to a vineyard, or crafting a piece of art, the versatility of custom GI tie wire is a tool that facilitates innovation and structural integrity.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

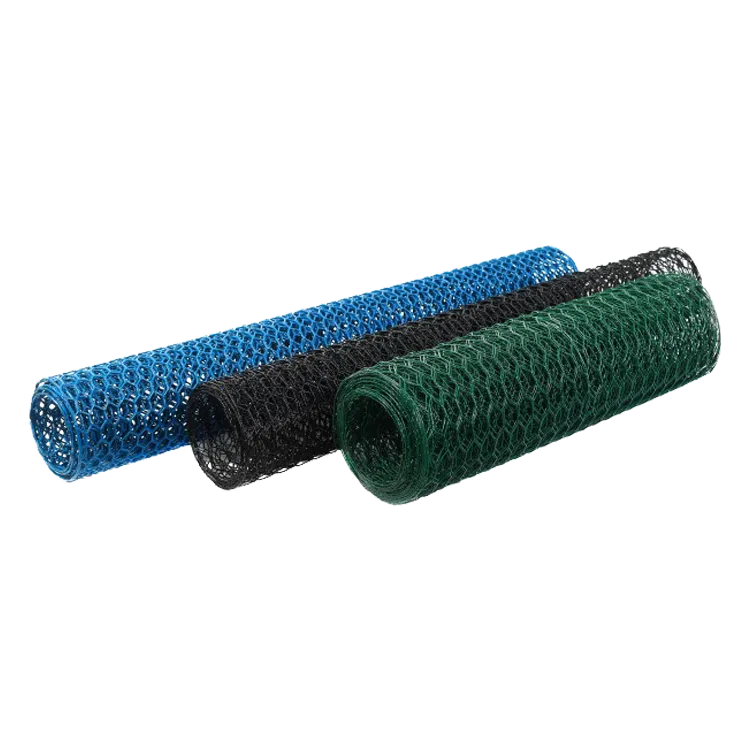

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025