Custom Galvanized Wire Cost per Ton in Current Market Trends

Understanding Custom Galvanized Wire Prices per Ton

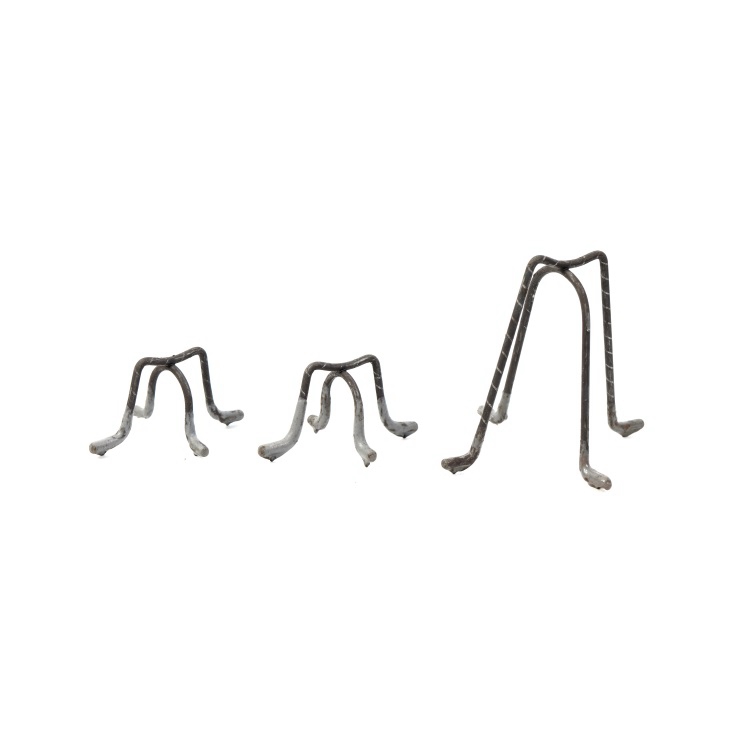

Galvanized wire has become an essential component in various applications, ranging from construction to agriculture and DIY projects. The process of galvanization involves coating the wire with a layer of zinc to enhance its resistance to corrosion, thus increasing its durability and lifespan. As industries continue to evolve, the demand for custom galvanized wire has surged, leading to fluctuations in prices per ton. This article will delve into the factors influencing the price of custom galvanized wire and what consumers should consider when making purchases.

Factors Influencing Prices

1. Raw Material Costs The price of zinc, the primary material used in galvanization, is a significant factor. Zinc prices can be volatile, influenced by global supply and demand dynamics. For instance, any disruptions in mining operations, international trade policies, or geopolitical tensions in zinc-producing countries can lead to price hikes.

2. Production Processes The method used to produce galvanized wire can also affect the cost. Different processes, such as hot-dip galvanization and electro-galvanization, have varying costs associated with them. Hot-dip galvanization, although more robust and offering superior corrosion resistance, typically incurs higher production costs compared to electro-galvanization.

3. Customization Customization of galvanized wire, including alterations in diameter, length, tensile strength, and coil weight, adds another layer to the pricing structure. The more specialized the wire needed, the higher the cost may be due to increased manufacturing complexity and time.

4. Market Demand The demand for galvanized wire can fluctuate based on seasonality and economic conditions. For instance, during construction booms, the demand for custom galvanized wire typically rises, causing prices to increase. Conversely, in downturns, prices may fall due to decreased demand.

custom galvanized wire price per ton

5. Quantity Purchased Bulk purchases often come with discounts. Buyers looking to stock large amounts of custom galvanized wire usually negotiate better pricing, which reflects economies of scale in production.

Quality Considerations

When considering the purchase of custom galvanized wire, quality should be a primary concern. Lower-priced products may sometimes imply compromises in quality which can lead to premature rusting and failure in applications. It’s crucial to balance cost with quality to ensure that the wire meets industry standards and will perform effectively over time.

Finding the Best Price

To secure the best price for custom galvanized wire, buyers should engage in market research. Comparing prices from different suppliers, checking industry trends, and keeping abreast of zinc market fluctuations can help in making informed purchasing decisions. Establishing long-term relationships with suppliers can also lead to more favorable terms and pricing as trust is built over time.

Conclusion

Ultimately, the price per ton of custom galvanized wire is influenced by a variety of factors, from raw material costs to market demand and production processes. As industries increasingly rely on quality galvanized wire for their projects, understanding these dynamics is crucial for making cost-effective and informed purchasing decisions. By considering both price and quality, consumers can ensure they are investing in a product that will provide value and durability in their specific applications.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025