Concrete Nail Production from Drawn Wire by Leading Manufacturer

The Process of Manufacturing Concrete Nails from Drawn Wire

Concrete nails are a vital component in the construction industry, particularly for fastening materials to concrete surfaces. They are specifically designed to penetrate hard surfaces, providing the strength and durability needed for various applications. The process of manufacturing concrete nails begins with the use of drawn wire, which is essential to ensure that the nails are sturdy and reliable. This article discusses the steps involved in the production of concrete nails, emphasizing the significance of drawn wire in the manufacturing process.

Step 1 Wire Drawing

The first step in the manufacturing process is the production of drawn wire. The wire is typically made from high-carbon steel, which is chosen for its exceptional strength and hardness. The raw steel is first heated and then drawn through a series of dies to reduce its diameter and increase its length. This process not only shapes the wire but also aligns the crystalline structure of the steel, enhancing its tensile strength. The drawn wire must have precise dimensions, as the diameter directly affects the quality and performance of the finished concrete nails.

Step 2 Wire Straightening and Cutting

Once the wire is drawn to the desired specifications, it undergoes straightening and cutting. The drawn wire often has slight bends or kinks that need to be eliminated to ensure uniformity in the nail length. Straightening machines use rollers to achieve this, creating a continuous straight wire that is easier to handle in the subsequent steps. After straightening, the wire is cut into predetermined lengths based on the specific requirements for different sizes of concrete nails.

Step 3 Pointing

The next step in the manufacturing process is pointing the wire segments. Each segment is fed into a pointing machine, where one end is shaped into a sharp point. This process involves mechanically grinding the end of the wire, creating a conical tip that allows for easier penetration into concrete materials. The sharp point is crucial, as it significantly reduces the force needed to drive the nail into hard surfaces, making it more effective for construction purposes.

concrete nails making drawn wire manufacturer

Step 4 Heat Treatment

After pointing, the nails undergo heat treatment, which is essential for enhancing their strength and wear resistance. The nails are heated in a controlled environment, followed by rapid cooling, a process known as quenching. This treatment alters the molecular structure of the steel, resulting in improved hardness and tensile strength. The heat treatment process is critical, as it ensures that the nails can withstand the stresses associated with being driven into concrete without bending or breaking.

Step 5 Surface Coating

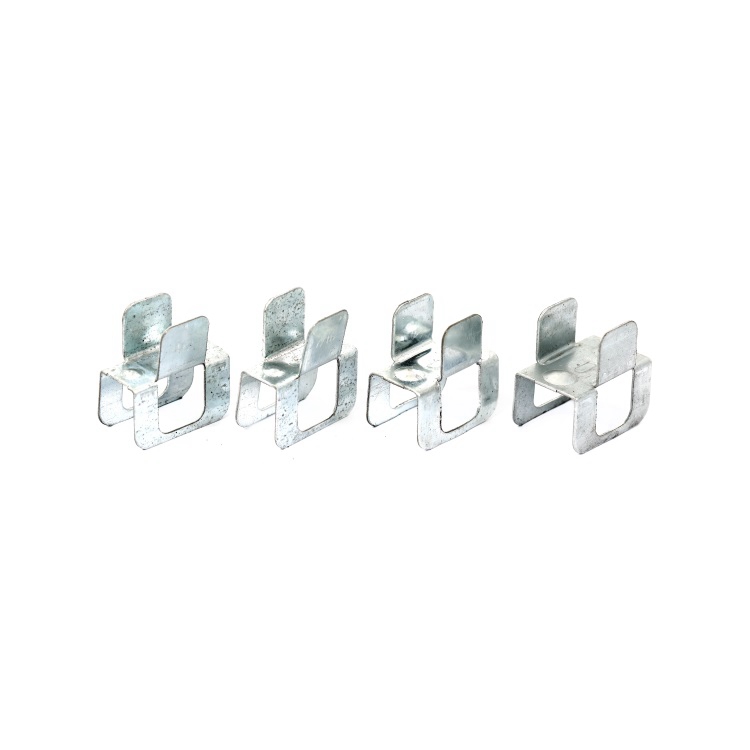

To protect the nails from corrosion and improve their longevity, a surface coating is applied. Common methods for coating include galvanization, where nails are dipped in a zinc solution, and other coatings that enhance rust resistance. This step is essential for ensuring that the nails maintain their integrity over time, especially when exposed to moisture or harsh environmental conditions during their application in construction projects.

Step 6 Quality Control and Packaging

The final step in the manufacturing process involves rigorous quality control measures. Each batch of concrete nails is tested for various parameters, including strength, durability, and dimensional accuracy. Any defects are identified and rectified before the nails are ultimately packaged for distribution. Adequate packaging ensures that the nails reach the customers in perfect condition, ready for use in various construction projects.

Conclusion

The manufacturing of concrete nails from drawn wire is a meticulous process that ensures the production of high-quality fasteners for the construction industry. From wire drawing to quality control, each step is designed to enhance the performance and durability of the finished product. As construction continues to evolve, the demand for reliable and efficient fastening solutions like concrete nails remains paramount, underscoring the importance of advanced manufacturing techniques in ensuring construction safety and integrity.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025