Concrete Nail Production Facility for High-Quality Fasteners and Construction Solutions

The Concrete Shoot Nail Factory Revolutionizing Construction Fasteners

In the ever-evolving world of construction, the need for reliable and efficient fastening solutions has never been more critical. Among various fastening methods, concrete shoot nails have emerged as a highly effective option, particularly in applications involving concrete and masonry. At the forefront of this innovation is the concrete shoot nail factory, a specialized facility dedicated to the manufacturing of these essential construction components.

Understanding Concrete Shoot Nails

Concrete shoot nails, also known simply as shoot nails or powder-actuated fasteners, are designed to be driven into concrete, steel, or masonry surfaces using a powder-actuated tool (PAT). This technology allows for rapid installation, significantly reducing labor and time compared to traditional drilling and anchoring methods. The nails are engineered for durability and strength, often made from high-quality steel, and are available in various lengths and diameters to meet the diverse needs of construction projects.

The Manufacturing Process

The production of concrete shoot nails involves several intricate steps that ensure high quality and performance. It begins with sourcing raw materials, typically steel rods, which are subjected to rigorous quality control checks. The steel is then processed through precise shaping and cutting techniques, transforming it into various nail sizes and configurations.

Next, the nails undergo heat treatment to enhance their hardness and tensile strength. This step is crucial, as it determines the fasteners' ability to withstand the rigors of construction environments. After heat treatment, the nails are often coated with a corrosion-resistant finish to enhance their longevity, especially when used in outdoor or high-moisture applications.

The final phase of manufacturing involves packaging and labeling the nails, ensuring they meet industry standards and regulations. Quality control is a continuous process, with each batch of nails subjected to testing for performance characteristics such as shear strength, pull-out resistance, and overall durability.

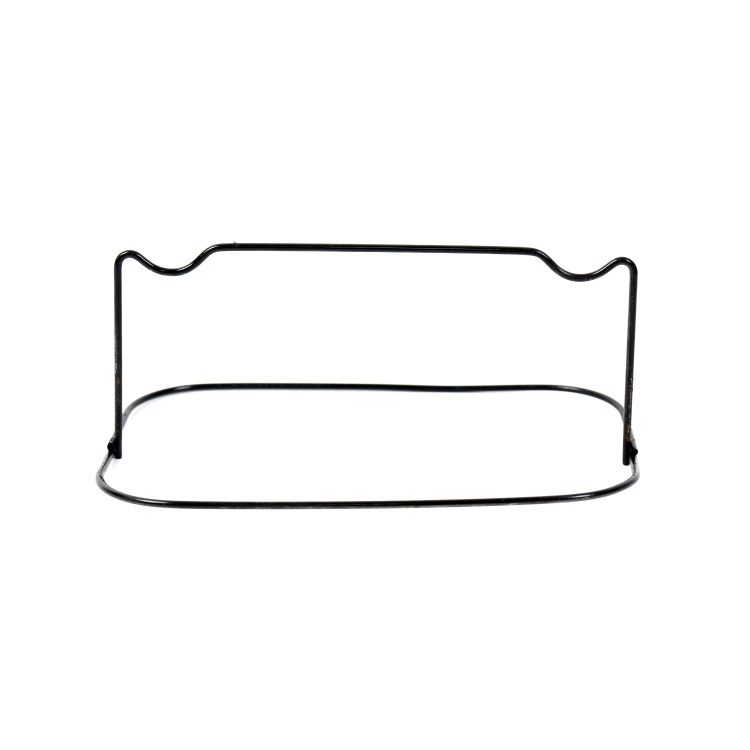

concrete shoot nail factory

Innovation and Technology

Modern concrete shoot nail factories are equipped with advanced technologies that facilitate precision manufacturing and improve efficiency. Automation plays a significant role in enhancing production speed while maintaining high quality. Automated systems reduce the risk of human error and allow for greater scalability in manufacturing.

Moreover, digital technologies, such as computer-aided design (CAD) and simulation software, are employed to optimize nail designs for specific applications, ensuring that customers receive the most effective fastening solutions. This focus on innovation not only enhances product performance but also drives competitive advantage in the marketplace.

Meeting Market Demand

As urbanization continues to rise, the demand for concrete shoot nails is growing. Industries such as construction, engineering, and infrastructure development heavily rely on these fasteners for their projects. The concrete shoot nail factory plays a vital role in meeting this demand by providing a steady supply of high-quality products that enhance efficiency and safety on job sites.

Sustainability is also a growing concern in the manufacturing sector. Many concrete shoot nail factories are adopting eco-friendly practices, such as recycling waste materials and reducing energy consumption during production, to minimize their environmental footprint. This commitment to sustainability not only appeals to environmentally conscious consumers but also aligns with global initiatives aimed at reducing industrial impacts on the planet.

Conclusion

In conclusion, the concrete shoot nail factory is a cornerstone of modern construction technology, providing essential fasteners that enhance efficiency, safety, and durability in building projects. As technology advances and market demands evolve, these factories will continue to innovate, ensuring that the construction industry has access to the best fastening solutions available. Emphasizing quality, efficiency, and sustainability, the concrete shoot nail factory exemplifies the intersection of tradition and modernity in the construction sector, making significant contributions to the future of building and infrastructure development.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025