Top Manufacturers of Common Nail Building Materials in the Construction Industry

The Role of Common Nail Building Material Manufacturers in Construction

In the construction industry, the importance of durable and reliable building materials cannot be overstated. Among these materials, common nails play an essential role. They are ubiquitous and serve as a fundamental component in various construction and woodworking projects. The manufacturers of these common nail building materials are crucial players in the supply chain, ensuring that quality, efficiency, and innovation are maintained in the marketplace.

Understanding Common Nails

Common nails, typically made of steel, are designed for general construction purposes. They are characterized by their thicker shafts and larger heads, providing superior holding power when fastening materials together. Common nails are used in everything from framing wooden structures to attaching roofing materials. Their versatility makes them a staple in both residential and commercial construction projects.

Manufacturing Process

The manufacturing of common nails involves several critical steps that ensure their quality and durability. First, manufacturers start with high-quality raw materials, primarily steel, as it offers the strength required for various applications. The steel is heated and drawn into wire of the appropriate diameter, which is an important step in producing nails of varying sizes and specifications.

Once the wire is drawn, it is cut to the desired lengths and then shaped into nails using a series of automated machines. These machines not only cut but also form the head of the nail, ensuring that it can hold against driving forces. Quality control is an integral part of this process as well; manufacturers conduct rigorous testing to ensure that the nails meet industry standards and can withstand the pressures often encountered in construction.

Importance of Quality

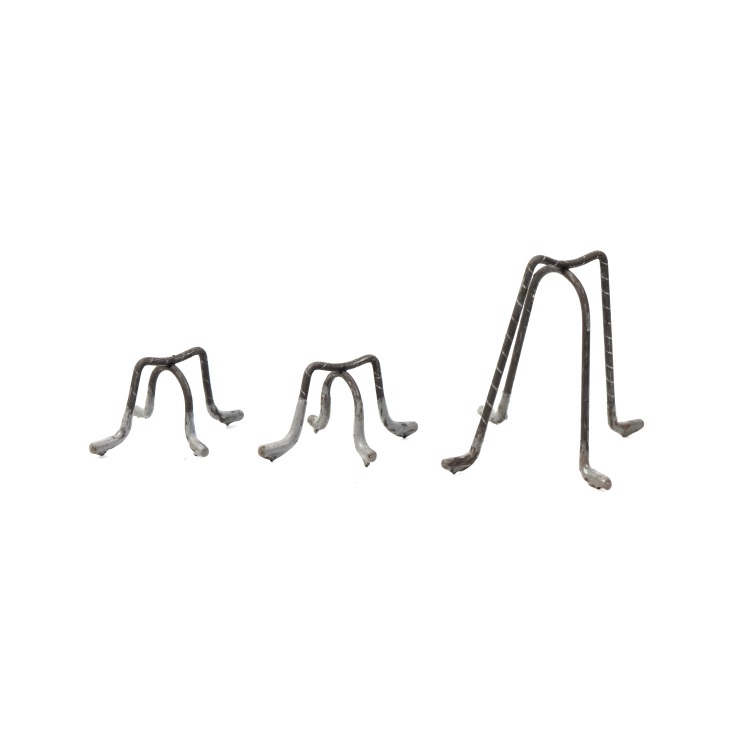

common nail building material manufacturers

The quality of common nails can significantly affect the strength and longevity of a construction project. Inferior nails can bend, break, or rust prematurely, leading to structural failures and costly repairs. Therefore, it is critical for manufacturers to adhere to strict quality control measures throughout the production process. This includes sourcing high-grade materials, utilizing advanced manufacturing technologies, and conducting thorough testing of the finished products.

Trends in Nail Manufacturing

As the construction industry evolves, so too does the demand for innovative building materials, including nails. Manufacturers are increasingly focusing on technological advancements to enhance the properties of common nails. For example, the development of galvanized and stainless-steel nails has gained popularity, as these materials offer improved corrosion resistance. This is especially important in regions with high humidity or exposure to the elements, where regular nails might deteriorate quickly.

Another trend is the move towards sustainable manufacturing practices. Many manufacturers are exploring eco-friendly alternatives, such as sourcing recycled materials and optimizing production processes to reduce waste. This shift not only helps in conserving the environment but also appeals to contractors and builders looking to meet sustainability targets.

Conclusion

Common nail building material manufacturers play an indispensable role in the construction industry. Their commitment to quality, innovation, and sustainability drives the efficiency and reliability of construction projects. As the industry continues to evolve, the demand for high-quality nails will only grow, making it imperative for manufacturers to keep pace with new technologies and materials.

In summary, while often overlooked, common nails are a fundamental component of construction. The manufacturers behind these vital products ensure that builders have access to the materials necessary for creating robust and lasting structures. As we move forward in a rapidly changing construction landscape, the collaboration between manufacturers and builders will be essential in driving innovation and maintaining high standards in building practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025