Colored Barbed Wire Production and Supplier for Enhanced Security and Aesthetics

The Rise of Colored Barbed Wire Manufacturers Safety, Aesthetics, and Functionality

In the world of fencing solutions, colored barbed wire is emerging as a unique and dynamic product, catering not only to security needs but also to aesthetic preferences. As a colored barbed wire manufacturer, it's essential to understand the market's demands, technological advancements, and the potential applications of this innovative product. This article explores the increasing popularity of colored barbed wire, the manufacturing process, and its diverse applications across different sectors.

Understanding Colored Barbed Wire

Traditionally, barbed wire has been used primarily for security and confinement, particularly in agricultural settings to keep livestock contained. However, the conventional silver-colored galvanized wire has its limitations, particularly when it comes to blending into the environment. Colored barbed wire offers an innovative solution, as it provides the same level of security while enhancing the visual appeal of fences.

Colored barbed wire is manufactured by applying a layer of colored coating to the wire. This coating not only provides an aesthetic advantage but also adds an additional layer of protection against corrosion and rust. Various colors are available, allowing customers to choose options that best match their landscapes or branding requirements.

Manufacturing Process

The process of manufacturing colored barbed wire involves several key stages

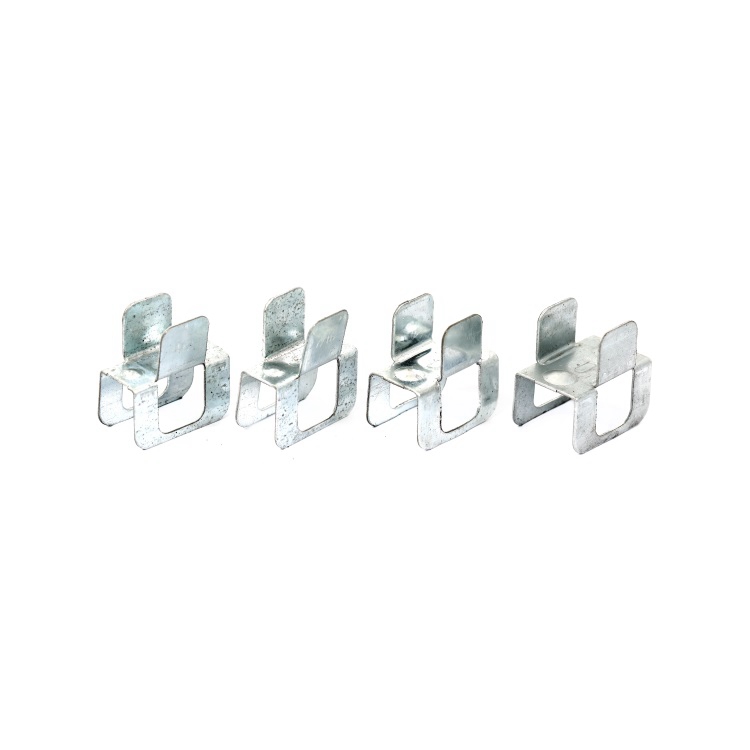

1. Material Selection Manufacturers typically use high-quality steel for the wire, ensuring durability and strength. The wire is often galvanized to resist rust and corrosion.

2. Barbing and Twisting Once the material is selected, the wire is twisted and barbed. This process can be done mechanically to ensure precision and consistency in the dimensions.

3. Color Coating After the wire is shaped, it undergoes a coloring process. This may involve powder coating or using specific paint formulations that adhere well to the metal surface. This step is crucial, as it ensures that the color is not only appealing but durable enough to withstand environmental factors.

colored barbed wire manufacturer

4. Quality Control Finished products undergo rigorous quality control checks to ensure they meet safety and durability standards. Manufacturers test for tensile strength, resistance to environmental factors, and consistency in color.

5. Packaging and Distribution Finally, colored barbed wire is packaged for distribution. Manufacturers often offer different lengths and roll sizes to appeal to a variety of customer needs.

Applications and Market Demand

The demand for colored barbed wire is on the rise due to its versatility across multiple sectors

- Agriculture Farmers are increasingly opting for colored barbed wire to secure their livestock while ensuring that the fencing blends in with the surroundings, enhancing the landscape's natural beauty.

- Commercial Use Businesses are also utilizing colored barbed wire to fortify their perimeters. The visual aesthetic of colored wire can align with branding strategies, offering an additional marketing angle.

- Residential Fencing Homeowners are finding colored barbed wire to be an attractive option for securing their properties without compromising on style. Fences can be customized to match the home’s exterior, creating a cohesive look.

- Industrial Applications Industries requiring robust security solutions are employing colored barbed wire for their sites not only for safety but also to create a less intimidating environment for visitors.

Conclusion

As a colored barbed wire manufacturer, understanding the intricacies of the product, its manufacturing processes, and its diverse applications is crucial. With the growing awareness of aesthetic considerations in security fencing, there lies an opportunity to cater to a market eager for both functionality and style. By focusing on quality manufacturing, innovative coloring techniques, and targeted marketing strategies, manufacturers can position themselves as leaders in this evolving sector. Colored barbed wire is more than just a security measure; it represents a new era in fencing solutions that marry safety with aesthetics, promising a bright future for both manufacturers and consumers alike.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025