cold drawn galvanized wire manufacturers

Understanding Cold Drawn Galvanized Wire An Overview of Manufacturers and Their Offerings

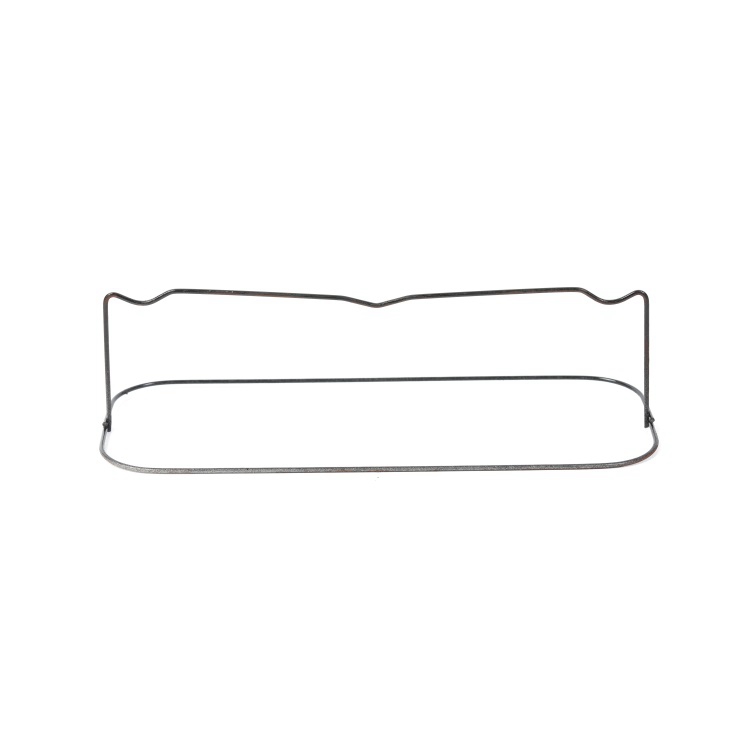

Cold drawn galvanized wire is a manufacturing marvel that combines the benefits of both cold drawing and galvanization to produce a highly versatile and durable product used in a variety of applications. The process of cold drawing involves pulling the wire through a die to achieve a smaller diameter, which enhances its strength and durability. Subsequent galvanization, typically through hot-dipping, coats the wire with a protective layer of zinc, preventing corrosion and extending its lifespan significantly.

Applications of Cold Drawn Galvanized Wire

The versatility of cold drawn galvanized wire makes it suitable for numerous applications across different industries. It is widely used in construction for reinforcing concrete and in the manufacturing of wire meshes. Its strength and resistance to corrosion also make it an excellent choice for fencing, agricultural purposes, and in the automotive industry for various components. Additionally, its aesthetic qualities allow it to be employed in decorative applications, such as in garden art and fencing designs.

The Manufacturing Process

The production of cold drawn galvanized wire begins with high-quality raw materials, typically low-carbon steel. The steel is first subjected to a cold drawing process, which alters its physical properties. The drawing process can refine the wire into precise diameters and enhance its tensile strength through strain hardening. Following this, the wire undergoes galvanization, where it is coated with zinc to form a protective layer. This process not only improves the wire's resistance to rust and wear but also enhances its overall longevity.

Choosing the Right Manufacturer

When it comes to sourcing cold drawn galvanized wire, selecting a reputable manufacturer is essential. Several key factors to consider include

cold drawn galvanized wire manufacturers

1. Quality Assurance The manufacturer should adhere to industry standards and certifications. ISO certification is a good indicator of a commitment to quality control. 2. Production Capabilities A manufacturer with advanced machinery and technology will be able to produce wire that meets specific requirements in terms of diameter, tensile strength, and coating thickness.

3. Experience and Reputation Manufacturers with a long-standing presence in the industry are often more reliable. Check customer reviews and testimonials to gauge their service quality and product reliability.

4. Range of Products A diverse product line indicates the manufacturer's capability to meet various needs. Look for those who can provide custom solutions tailored to specific applications.

5. Customer Support Good manufacturers provide excellent customer service, helping clients understand their requirements and offering technical support when needed.

Industry Trends

The cold drawn galvanized wire market is experiencing several trends driven by technological advancements and shifting consumer demands. Manufacturers are increasingly focusing on sustainability, implementing eco-friendly practices in both their wire production and galvanization processes. Additionally, there is a growing demand for innovative products, such as wires with enhanced coating technologies that offer even better corrosion resistance.

Conclusion

Cold drawn galvanized wire plays a critical role in a variety of sectors, thanks to its strength, durability, and resistance to corrosion. As industries continue to evolve, the manufacturers of this wire must adapt and innovate, ensuring their products meet modern demands. With the right combination of quality assurance, technological advancement, and customer-centric practices, reputable manufacturers can not only thrive in this competitive market but also contribute to the development of high-quality, sustainable solutions that shape the future of construction, manufacturing, and beyond. Choosing the right manufacturer is essential for ensuring that your projects benefit from high-quality materials that stand the test of time.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025