china gi electro welded wire mesh

The Rise of China’s GI Electro Welded Wire Mesh An Overview

In recent years, galvanized iron (GI) electro welded wire mesh has emerged as a significant product in the construction, agriculture, and industrial sectors. This innovative material, prominently produced in China, has been gaining worldwide attention for its superior durability, versatility, and cost-effectiveness.

Understanding GI Electro Welded Wire Mesh

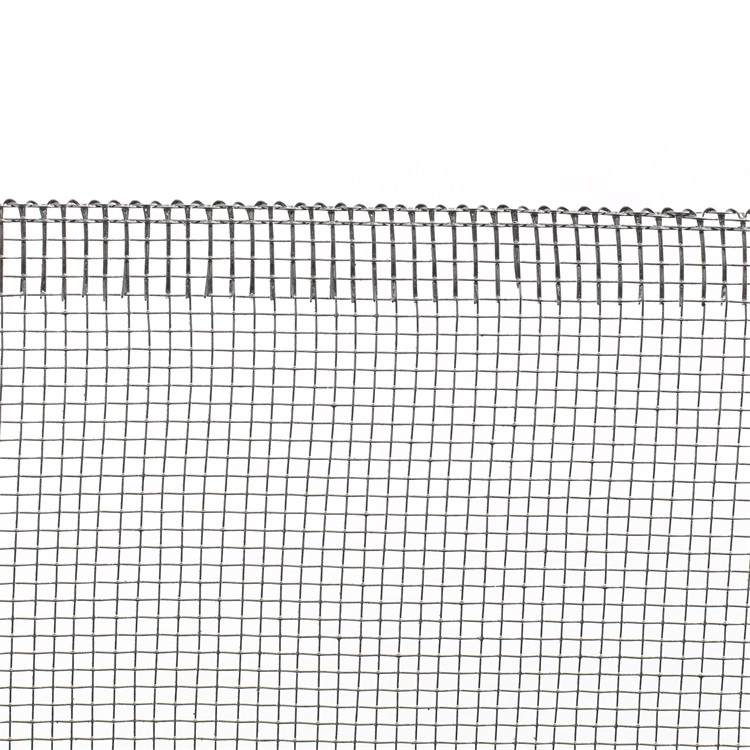

GI electro welded wire mesh is made from high-quality low-carbon steel wires that are coated with a layer of zinc to prevent corrosion. The wires are welded together at their intersections using an electric resistance welding process, which ensures the mesh is both strong and stable. This welding method provides a seamless and uniform structure, making it ideal for various applications.

The galvanized coating greatly enhances the wire mesh's resistance to rust and degradation, making it suitable for outdoor usage and environments with high humidity. The standard wire gauges used in the manufacture of GI welded wire mesh vary, allowing for various levels of strength and flexibility depending on the project's requirements.

Applications of GI Electro Welded Wire Mesh

One of the primary applications of GI electro welded wire mesh is in the construction industry. It serves as a reinforcement material in concrete and masonry, providing additional support and stability to structures. Furthermore, its lightweight yet robust nature makes it easier to handle and install compared to traditional reinforcement materials.

In the agricultural sector, GI welded wire mesh is widely used for fencing purposes. It effectively keeps livestock contained and protects crops from pests. Additionally, it’s utilized in making animal enclosures, ensuring safety while allowing for ventilation.

china gi electro welded wire mesh

Manufacturers also exploit GI wire mesh in various industrial applications. It is commonly used for sieving, filtering, and protecting machinery from external elements. Its ability to resist wear and tear under harsh environmental conditions contributes to its popularity among manufacturing industries.

Advantages of Choosing GI Electro Welded Wire Mesh

One of the main advantages of GI electro welded wire mesh is its cost-effectiveness. The production process in China allows for competitive pricing, making it an appealing option for both small-scale projects and large industrial applications. The long lifespan provided by the galvanized coating reduces replacement and maintenance costs over time.

Moreover, GI welded wire mesh is easy to install. Its rigidity and prefabricated nature allow for quick setup, thus saving labor costs and time on construction sites. The flexibility in design ensures that it can be customized to meet specific project needs, accommodating different shapes and sizes.

Environmental Considerations

With growing environmental awareness, the production and use of GI electro welded wire mesh align with sustainable practices. The zinc coating is environmentally friendly, providing a protective layer without harmful side effects. Additionally, the material is recyclable, which minimizes waste and supports recycling initiatives in the construction and manufacturing industries.

Conclusion

As the demand for durable, versatile, and cost-effective building materials continues to rise, the global market for GI electro welded wire mesh is poised for growth. China’s advancements in manufacturing and technology contribute significantly to this trend, making it a leader in the production of high-quality wire mesh. With broad applications across various sectors, this innovative material is set to play an integral role in shaping the future of construction and industrial practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025