China 2015 Coil Nail Wire Pallet Size 2 x 0.099 for Construction Needs

Understanding the 2015 Degree Wire Pallet Coil Nail A Comprehensive Overview

In the world of construction and woodworking, fasteners are essential components that hold everything together. Among these, nails play an integral role, with various types suited for different applications. One such type is the 2015 degree wire pallet coil nail, a specific fastener that has gained popularity in recent years, particularly within the pallet manufacturing and construction industries. This article aims to delve into the characteristics, applications, advantages, and market trends of the 2015 degree wire pallet coil nail.

Characteristics of 2015 Degree Wire Pallet Coil Nails

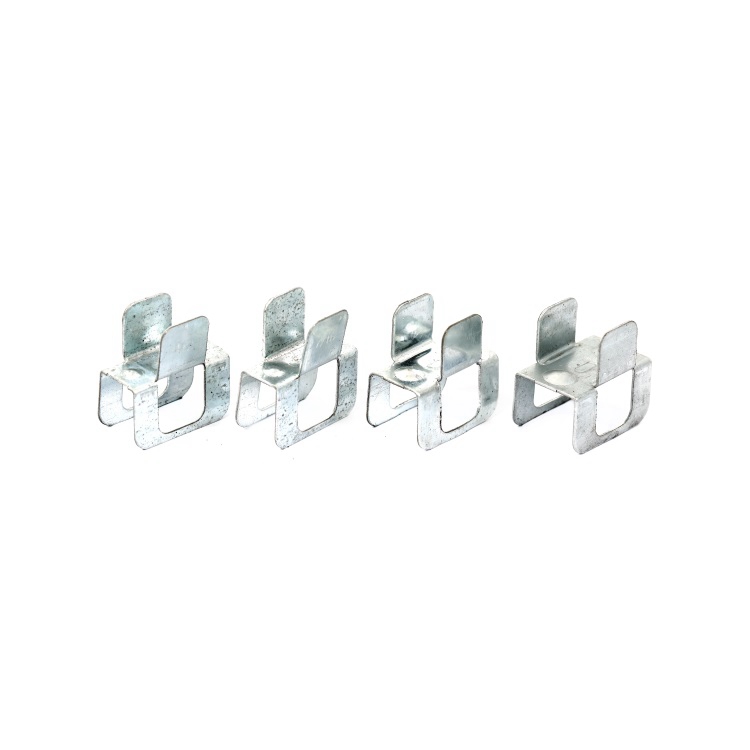

The 2015 degree wire pallet coil nail is designed for use with coil nailers, which are specialized tools that enable rapid nailing in various applications. The term 2015 degree refers to the angle at which the nails are collated within the coil, allowing for efficient and effective nailing processes. These nails are typically made from high-quality steel, ensuring strength and durability under pressure.

The specifications for these nails often include a diameter of approximately 0.099 inches and a length that can vary depending on the specific project requirements. Their design allows for a strong hold, making them particularly suited for fastening wooden pallets, crates, and other structures. Additionally, they are often paired with various coatings, such as galvanized or polymer, to enhance rust and corrosion resistance, thereby prolonging the life of the fastened structures.

Applications of 2015 Degree Wire Pallet Coil Nails

The primary application of 2015 degree wire pallet coil nails is in the manufacturing of wooden pallets. These pallets are critical in the logistics and transportation industry, facilitating the safe and efficient movement of goods. The strength and reliability of the pallet are directly impacted by the quality of the fasteners used, making the choice of the right nail essential.

In addition to pallet manufacturing, these coil nails are also widely used in framing, roofing, and other construction applications where speed and efficiency are paramount. The ability to quickly load a coil nailer with a large quantity of nails allows workers to complete tasks with significantly less downtime compared to traditional nail driving methods.

china 15 degree wire pallet coil nail 2 x .099

Advantages of Using 2015 Degree Wire Pallet Coil Nails

One of the standout advantages of using 2015 degree wire pallet coil nails is their efficiency. The design of coil nails allows nailers to hold numerous fasteners in a single coil, resulting in fewer reloads and increased productivity. Workers can make quick work of nailing jobs, which is especially vital in high-volume manufacturing or construction situations.

Additionally, the strong holding power of these nails, coupled with their resistance to bending or breaking, ensures secure and lasting connections between materials. This durability can lead to cost savings over time, as properly fastened structures require less maintenance and are less likely to suffer from structural failures.

Moreover, the various coating options available for these nails contribute to their overall versatility and long-lasting performance. For instance, galvanized options provide excellent protection against rust, making them suitable for outdoor applications or environments with high humidity.

Market Trends and Future Outlook

As the construction and pallet manufacturing industries continue to evolve, the demand for high-quality fasteners such as the 2015 degree wire pallet coil nail is expected to grow. The push toward automation and efficiency in manufacturing processes further underscores the importance of reliable nailing solutions.

Moreover, the rise of e-commerce and the subsequent increase in demand for logistics solutions have fueled the need for durable and efficient pallet production. As businesses seek to minimize costs and maximize productivity, the adoption of advanced nail technology, including coil nails, will play a crucial role in meeting these challenges.

In conclusion, the 2015 degree wire pallet coil nail serves as a vital component in the construction and pallet manufacturing sectors. Its design, efficiency, and strength make it an indispensable tool for professionals looking to improve productivity and ensure structural integrity. With ongoing industry developments and increased focus on quality, the future for this specific type of fastener looks promising. As we move forward, innovations in both fastener technology and application techniques will continue to shape the landscape of construction and manufacturing.

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025