bwg16 black annealed tie wire manufacturers

Understanding BWG16 Black Annealed Tie Wire Manufacturers and Applications

Black annealed tie wire is a vital component in various construction and manufacturing processes, crucial for its durability, flexibility, and overall performance. Among different gauges of tie wire, BWG 16 (Birmingham Wire Gauge 16) is popular for numerous applications. This article delves into the characteristics, manufacturing process, and applications of BWG16 black annealed tie wire, along with insights into leading manufacturers in the industry.

What is BWG16 Black Annealed Tie Wire?

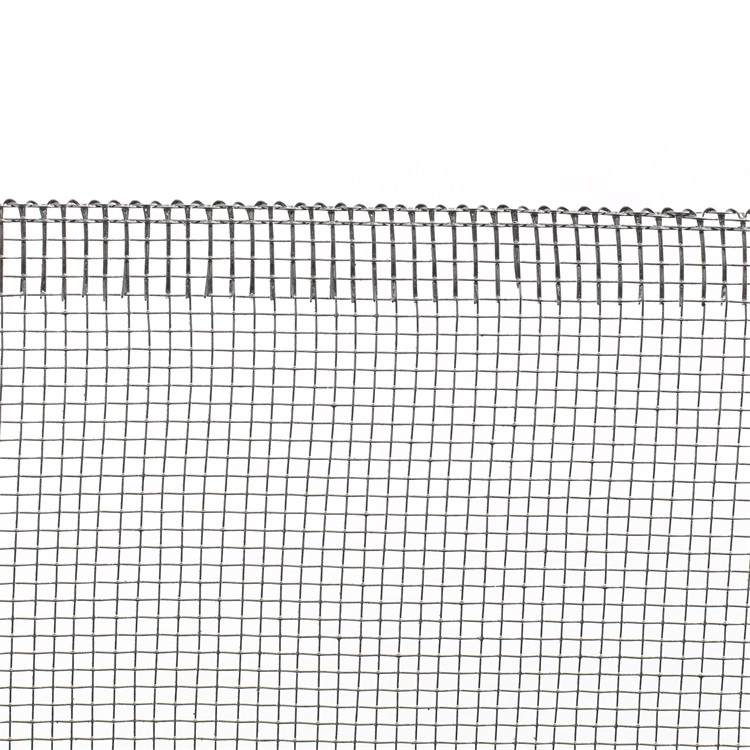

BWG16 black annealed tie wire is a form of wire produced from low carbon steel. The term black indicates that the wire does not have a shiny surface; instead, it retains a dark finish due to the production process. Annealed refers to a heat treatment process that enhances the wire's malleability and softness, making it easy to work with. The gauge number, 16, signifies the diameter of the wire, which typically measures around 1.29 mm (0.0508 inches).

This type of tie wire is available in various lengths and is widely used in industries such as construction, agriculture, and packaging.

Manufacturing Process of BWG16 Tie Wire

The manufacturing process of BWG16 black annealed tie wire involves several key steps

1. Wire Drawing The process begins with transferring raw steel rods through a series of dies that progressively reduce the diameter. This drawing process enhances the strength and quality of the wire.

2. Annealing After reaching the desired gauge, the wire is subjected to annealing, where it is heated in a controlled environment. This process reduces the internal stresses and makes the wire more pliable.

3. Drawing and Coating Once annealed, the wire undergoes another drawing process to attain the final specifications, followed by a coating in some cases to enhance corrosion resistance.

Applications of BWG16 Black Annealed Tie Wire

bwg16 black annealed tie wire manufacturers

The versatility of BWG16 black annealed tie wire allows it to serve a multitude of functions across different sectors

1. Construction In the construction industry, BWG16 tie wire is commonly used for tying rebar together. It is essential in reinforcing concrete structures to ensure stability and integrity.

2. Agriculture Farmers use black annealed tie wire for various applications including binding plants, fencing, and supporting crops. Its flexibility allows farmers to secure plants to stakes or other supports effectively.

3. Manufacturing and Industry Manufacturers utilize BWG16 wire for packaging, metal fabrications, and in the production of wire mesh and other components. The wire’s strength makes it ideal for DIY projects and professional applications alike.

4. Crafting and DIY Projects The pliability of BWG16 black annealed tie wire makes it popular among artisans and crafters for various projects, including wreath-making, model construction, and decorative arts.

Leading Manufacturers

Several manufacturers are recognized for producing high-quality BWG16 black annealed tie wire. These manufacturers focus on quality control and innovation to meet market demands.

1. WireTech Industries Known for their advanced manufacturing techniques, WireTech Industries produces a wide range of tie wire products with strict adherence to international quality standards.

2. SteelWed Co. SteelWed has established itself as a leader in the production of tie wires, including BWG16. Their commitment to sustainability and efficient manufacturing practices has gained them a solid reputation in the industry.

3. FlexiTie Corp Specialized in producing flexible and durable tie wires, FlexiTie Corp offers a variety of options that cater to different industry needs, ensuring customer satisfaction and performance reliability.

Conclusion

BWG16 black annealed tie wire plays an integral role in construction, agriculture, manufacturing, and crafting. Its unique properties, coupled with a well-defined manufacturing process, make it a preferred choice for many applications. With reputable manufacturers prioritizing quality and innovation, BWG16 tie wire continues to fulfill industry demands effectively. As industries evolve and seek sustainable solutions, the relevance of high-quality tie wire will undoubtedly persist, cementing its place in the marketplace for years to come.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025