Manufacturers of Fasteners and Hardware Components for Various Industries

The Importance of Quality in Bolts and Nuts Manufacturing

In the world of manufacturing, the humble bolt and nut may seem like simple components. However, they are critical to the integrity of countless structures and machines across various industries. The manufacturing process of bolts and nuts is not just about mass production; it involves precision, quality control, and an understanding of the specific needs of different applications.

Bolts and nuts are classified as fasteners, which are devices that hold objects together. While bolts typically consist of a cylindrical shaft with external threads, nuts are internally threaded and are used in conjunction with bolts to secure components. The functionality and safety of machinery and structures often depend on these small yet essential components. Therefore, manufacturers must prioritize quality in their production processes to ensure reliability and safety.

The Importance of Quality in Bolts and Nuts Manufacturing

Once the materials are procured, advanced manufacturing techniques come into play. The manufacturing process usually includes forging, machining, and heat treatment. Forging is a process where the metal is shaped by applying compressive forces, enhancing its strength. Machining involves cutting and shaping the bolt or nut to precise dimensions, while heat treatment can alter the material properties to provide better resistance to wear and corrosion.

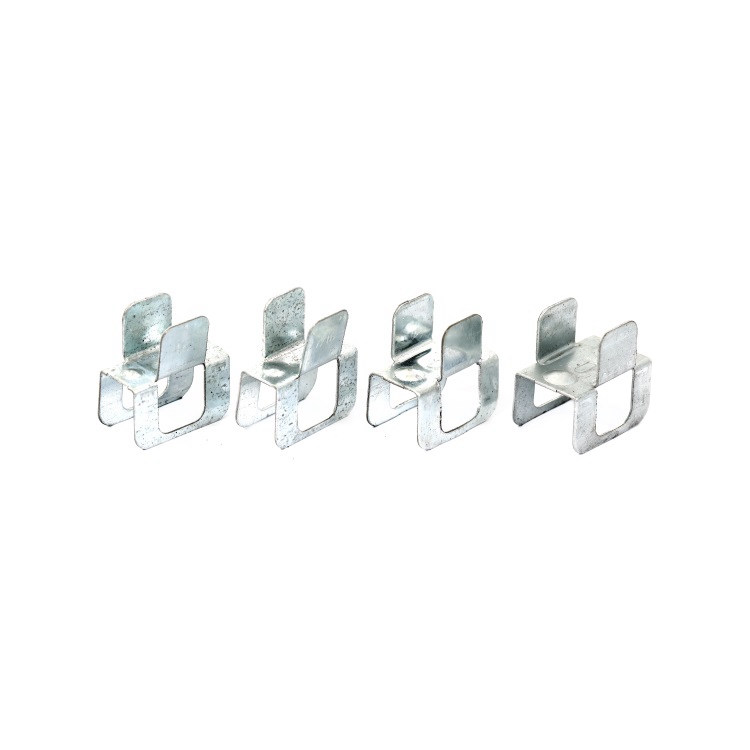

bolts and nuts manufacturer

Quality assurance is a critical aspect of bolts and nuts manufacturing. Manufacturers implement rigorous testing procedures to ensure that each batch meets safety and performance standards. This includes tensile strength tests, hardness tests, and dimensional checks. Some manufacturers also obtain certification from international standards organizations, underscoring their commitment to quality and safety.

Moreover, technological advancements have revolutionized the bolts and nuts manufacturing industry. Modern factories utilize automated machinery and robotics to enhance efficiency and precision. This not only speeds up production but also minimizes human error, resulting in higher-quality products. Additionally, the use of computer-aided design (CAD) allows manufacturers to create intricate designs tailored to specific applications, further broadening the scope of their product offerings.

Sustainability is another growing trend in the bolts and nuts manufacturing sector. Companies are increasingly seeking to minimize their environmental impact by using eco-friendly materials and sustainable manufacturing practices. Recycling materials and reducing waste are becoming more common, reflecting a broader commitment to responsible manufacturing.

In conclusion, while bolts and nuts may seem like insignificant components, their role in the manufacturing and construction industry cannot be overstated. A focus on quality, technological innovation, and sustainability is crucial for manufacturers to meet the growing demands of various sectors. As industries continue to evolve, the importance of reliable bolts and nuts will remain paramount, ensuring that the foundations of our modern world are secure and robust.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025