black annealed wire diameter 1.5mm exporter

The Importance of Black Annealed Wire in Construction and Manufacturing

Black annealed wire, especially in the diameter of 1.5mm, has become a pivotal material for various applications in construction and manufacturing. Its versatility, strength, and favorable properties make it an essential choice for many industrial processes. This article explores what black annealed wire is, its manufacturing process, its advantages, and its applications, particularly focusing on the export market for this essential material.

What is Black Annealed Wire?

Black annealed wire is a type of steel wire that has undergone an annealing process, which involves heating the wire to a high temperature and then cooling it down slowly. This process enhances the wire’s ductility and reduces its hardness, making it more flexible and easier to work with. The term black refers to the wire's dark, oxidized finish, which results from the manufacturing process.

The 1.5mm diameter specifically is a standard size that is commonly used in various applications, from construction to agricultural products. It strikes a balance between strength and flexibility, making it suitable for a range of tasks.

The Manufacturing Process

The production of black annealed wire begins with high-quality carbon steel wire rods. These rods are first drawn down to the desired diameter, and then they are subjected to the annealing process. During annealing, the wire is heated in a controlled environment, which promotes the recrystallization of the steel structure. This leads to improved mechanical properties, making the wire stronger yet more malleable.

Once annealed, the wires are cooled and typically coated with a rust-resistant material to prevent oxidation. This step is crucial as it preserves the quality of the wire, particularly for those being exported to markets that may expose them to harsh environmental conditions.

Advantages of Black Annealed Wire

1. Ductility One of the primary benefits of black annealed wire is its extraordinary ductility. This property allows it to be bent and twisted without breaking, making it ideal for applications requiring extensive manipulation.

2. Strength Despite being flexible, black annealed wire maintains a high tensile strength, enabling it to withstand significant amounts of tension.

3. Corrosion Resistance The annealing process helps enhance the wire's resistance to corrosion, especially when adequately coated, which is vital for extending the lifespan of the wire in construction and manufacturing applications.

black annealed wire diameter 1.5mm exporter

4. Eco-Friendliness The manufacturing of black annealed wire can be done with minimal environmental impact, especially when using advanced production techniques that prioritize sustainability.

Applications of Black Annealed Wire

The applications of 1.5mm black annealed wire are widespread

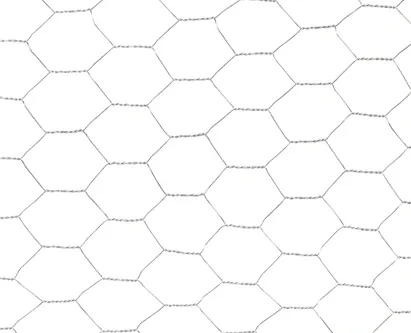

- Construction It is typically used in the construction of fences, gates, and other structures. Its flexibility allows it to be used in various forms, such as binding and securing materials.

- Agriculture Farmers often use black annealed wire for fencing, creating trellises, and tying plants, as its strength and durability are essential for outdoor use.

- Manufacturing This wire serves as a key component in producing different types of products, from wire baskets to more intricate machinery parts.

- Crafting Artisans and hobbyists appreciate the wire for its ease of manipulation, making it a favorite for various crafts and DIY projects.

The Export Market

As demand for black annealed wire continues to grow, the export market for this product is thriving. Countries around the world require this versatile material for their construction and manufacturing needs. Manufacturers of black annealed wire are focusing on meeting international standards to appeal to global markets, ensuring their products are of high quality and reliability.

In conclusion, 1.5mm black annealed wire is a vital component across many industries. Its unique blend of strength, flexibility, and resistance to environmental factors makes it a preferred choice for various applications. As the export market for this material continues to expand, it represents not just a segment of the global trade but also an integral part of modern construction and manufacturing practices.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025