Black Annealed Wire Manufacturing Processes and Factory Insights for Quality Production

The Role of Black Annealed Wire Construction Factories in Modern Infrastructure

In today's rapidly evolving construction industry, materials play a crucial role in ensuring the safety, durability, and sustainability of various structures. Among these materials, black annealed wire has emerged as a fundamental element, widely used in fencing, construction, and various industrial applications. Black annealed wire construction factories are pivotal in producing this essential material, and understanding their processes and contributions sheds light on the importance of this industry.

What is Black Annealed Wire?

Black annealed wire is a type of wire that is coated with a thin layer of iron oxide, giving it a characteristic black finish. This wire is made from low-carbon steel and is treated through a process of annealing, which involves heating the wire to high temperatures and then cooling it slowly. This process alters the wire's physical properties, making it more malleable and ductile while enhancing its strength. As a result, black annealed wire is particularly effective in applications that require flexibility and resilience, such as in construction, agriculture, and manufacturing.

The Manufacturing Process

The production of black annealed wire begins with drawing high-quality low-carbon steel rods through a series of dies to achieve the desired diameter. Once the wire has been drawn, it undergoes a heat treatment process, where it is heated in a controlled environment. This annealing process not only improves the wire’s mechanical properties but also prepares it for further processes such as galvanizing or coating, depending on the specific application requirements.

After annealing, the wire is often treated with a protective coating to prevent rust and corrosion, extending its lifespan. Factories employ various methods of coating, including oiling, to ensure that the wire remains in optimal condition during transport and storage. Quality control is paramount in these factories, as manufacturers must comply with industry standards to deliver products that meet the expectations of their clients.

Importance in Construction

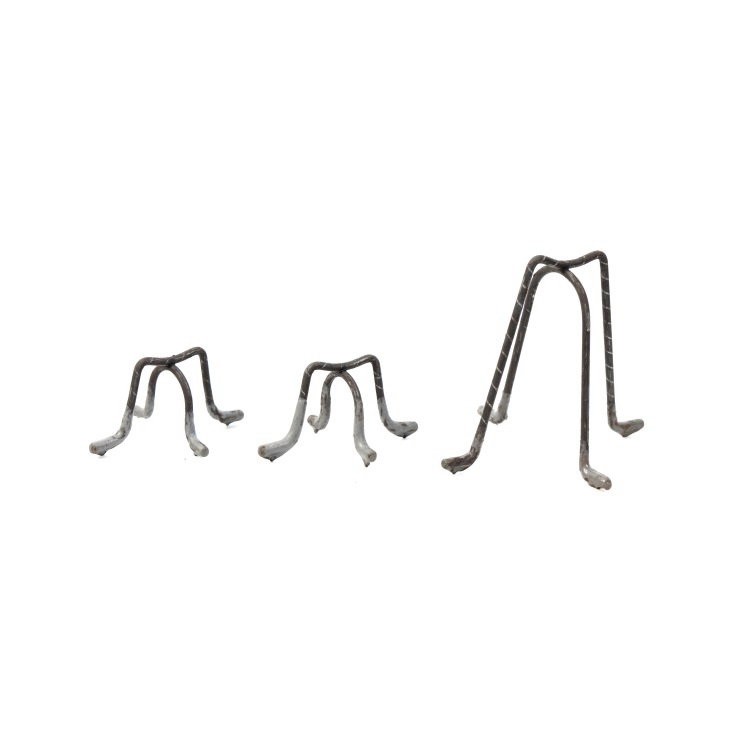

black annealed wire construction factories

Black annealed wire is especially popular in the construction industry due to its versatility and strength. It is commonly used for tying rebar, which is essential in concrete structures, ensuring stability and integrity. The wire's flexibility allows for easy manipulation, making it an ideal choice for builders who require materials that can adapt to various construction techniques.

Moreover, black annealed wire is widely used in the production of wire mesh and fencing materials. This gives it a vital role in constructing secure boundaries for residential, commercial, and industrial properties. The ability to withstand harsh weather conditions makes it an invaluable resource for long-term infrastructure projects.

Environmental Considerations

With the increasing focus on sustainability, black annealed wire construction factories are also adapting to more environmentally friendly practices. These factories are incorporating recycled materials into their production processes, reducing waste and energy consumption. The steel used in black annealed wire can often be sourced from recycled scrap steel, contributing to a circular economy. Additionally, many factories are investing in clean energy solutions to decrease their carbon footprint, aligning with global sustainability goals.

The Future of Black Annealed Wire Construction Factories

As the construction industry continues to grow, the demand for high-quality materials like black annealed wire is expected to rise. This growth will likely lead to advancements in manufacturing technologies, such as automated production lines and real-time quality monitoring systems. Furthermore, as trends in green building materials and sustainable practices become more prominent, black annealed wire factories will need to innovate continuously to meet evolving industry standards.

In conclusion, black annealed wire construction factories play a critical role in the contemporary construction landscape. By producing versatile, reliable materials, these factories not only contribute to the safety and durability of structures but also adapt to the pressing need for sustainable practices. As we move forward, the significance of these factories will only grow, solidifying their place at the backbone of modern infrastructure.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025