最佳焊接钢丝网的重量及其应用指南

Understanding the Weight of Welded Wire Mesh A Comprehensive Guide

Welded wire mesh is a versatile and durable material widely used in construction, agriculture, and various industrial applications. One critical aspect of welded wire mesh is its weight, which varies based on several factors, including the wire diameter, mesh spacing, and overall dimensions of the sheet. This article delves into the factors determining the weight of welded wire mesh and its implications for various uses.

Factors Influencing Weight

1. Wire Diameter The diameter of the wire is a significant factor affecting the weight of welded wire mesh. Thicker wires contribute more to the overall weight. For instance, a sheet made from 10-gauge wire will weigh considerably more than one made from 16-gauge wire, even if the sheet dimensions are the same.

2. Mesh Size The spacing between the wires, known as mesh size, also plays a crucial role in determining weight. Finer mesh sizes (more openings per square inch) generally require less material, thus reducing weight. In contrast, a larger mesh size means fewer wires are used, which can affect the mesh's structural integrity depending on the application.

3. Sheet Dimensions The overall size of the welded wire mesh sheet directly correlates with its weight. Larger sheets, regardless of wire diameter or mesh size, will weigh more simply due to their increased surface area.

4. Material Composition Welded wire mesh is commonly made from low-carbon steel, stainless steel, or galvanized steel. The type of material used can influence weight as well. For example, stainless steel is often heavier than regular carbon steel due to its alloy composition.

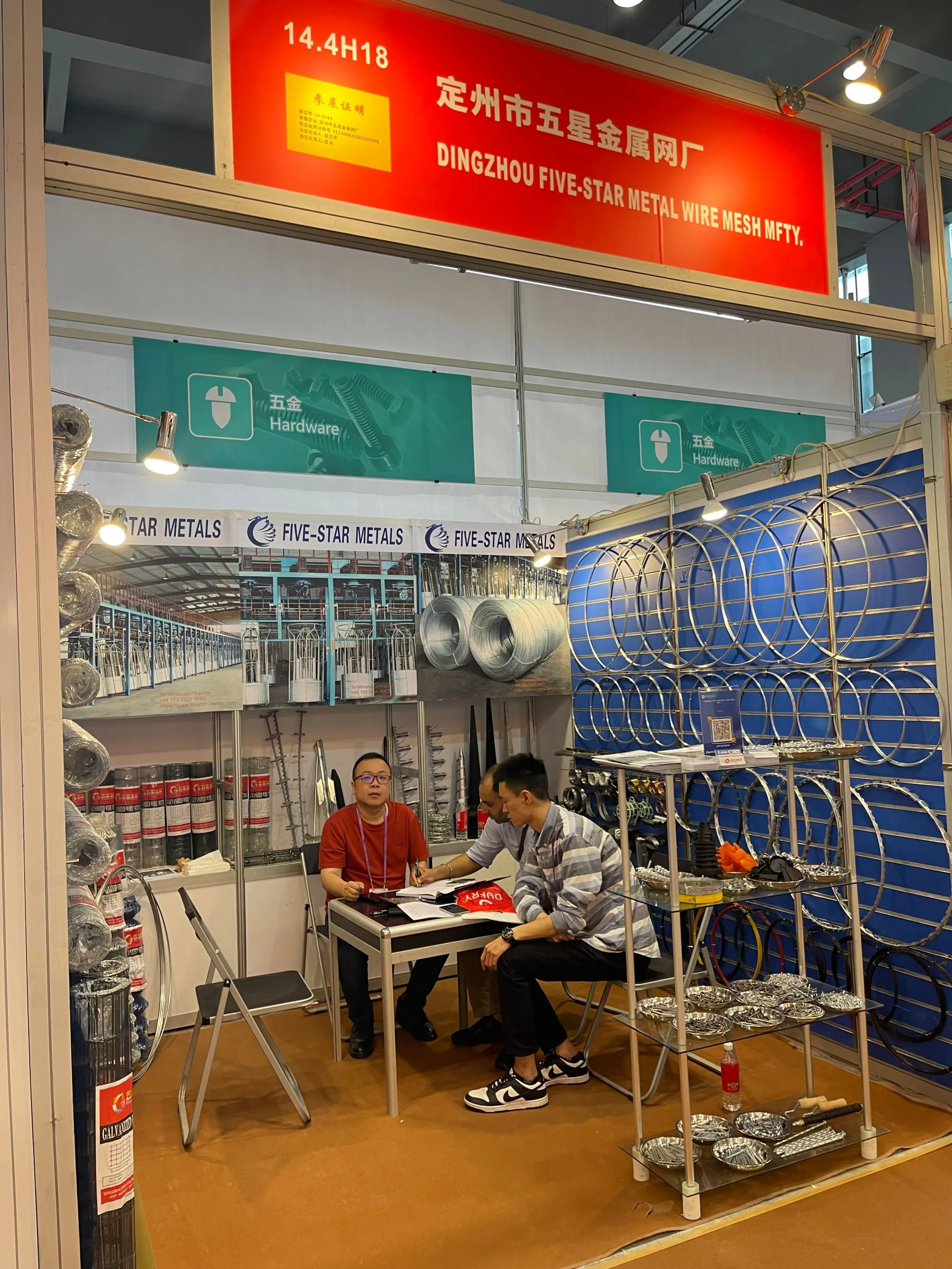

best welded wire mesh weight

Calculating Weight

To determine the weight of welded wire mesh, you can use the following formula

\[ \text{Weight (lbs)} = \text{Length (ft)} \times \text{Width (ft)} \times \text{Weight per square foot (lbs/ft}^2) \]

The weight per square foot can be derived from the wire gauge and mesh spacing from standard weight tables commonly available in industry literature.

Applications and Implications

Understanding the weight of welded wire mesh is crucial for professionals in construction and agriculture. A precise knowledge of weight aids in structural calculations, ensuring that installations comply with safety standards while also optimizing logistics. Lighter meshes may be preferred for applications requiring ease of handling, whereas heavier, more robust options might be necessary for projects demanding enhanced strength and durability.

In conclusion, the weight of welded wire mesh is influenced by a combination of wire diameter, mesh size, sheet dimensions, and material composition. By understanding these factors, buyers can make informed decisions tailored to their specific needs, ultimately leading to more efficient and effective project outcomes. Whether used for fencing, reinforcement, or as a component in various structures, the weight of welded wire mesh remains a pivotal aspect that should not be overlooked.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025