Top Quality Cold Drawn Galvanized Wire for Various Applications

The Benefits of Best Cold Drawn Galvanized Wire

Cold drawn galvanized wire is a popular choice across various industries due to its unique properties and numerous benefits. Understanding why this specific type of wire stands out can help consumers make informed decisions when selecting materials for their projects.

What is Cold Drawn Galvanized Wire?

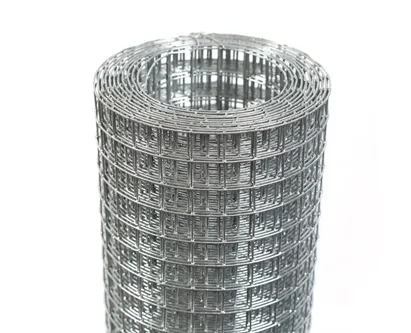

Cold drawn galvanized wire is created through a process that involves drawing wire through a die at room temperature to reduce its diameter and improve its strength. After this process, the wire is galvanized—coated with a layer of zinc to enhance its corrosion resistance. This combination of cold drawing and galvanization results in a wire that is not only strong and durable but also protected from rust and environmental damage.

Key Advantages

1. Enhanced Strength and Durability One of the primary benefits of cold drawn galvanized wire is its enhanced tensile strength. The cold drawing process aligns the wire’s internal structure, providing increased resistance to bending and deformation. This improved strength makes it ideal for applications requiring high load-bearing capacities, such as in construction and manufacturing.

2. Corrosion Resistance The galvanization process provides a protective layer of zinc, which acts as a barrier against environmental factors, including moisture and chemicals. This property is crucial in applications exposed to harsh environments, as it significantly prolongs the lifespan of the wire and reduces maintenance costs.

best cold drawn galvanized wire

3. Versatility Cold drawn galvanized wire is incredibly versatile and can be used in a variety of applications. It is commonly utilized in fencing, construction, and automotive industries. Additionally, its flexibility allows it to be manufactured in various gauges and lengths, catering to different project requirements.

4. Improved Appearance The smooth finish of cold drawn galvanized wire offers a clean aesthetic that is often preferred in visible applications. Its uniformity in appearance is especially important in decorative fencing, landscaping, and craft projects.

5. Cost-Effectiveness Although the initial cost of cold drawn galvanized wire may be higher than that of plain steel wire, its durability and corrosion resistance make it a more cost-effective solution over time. Reduced repair and replacement costs contribute to overall savings, making it a wise investment for businesses.

Applications of Cold Drawn Galvanized Wire

Cold drawn galvanized wire finds applications in various sectors. In construction, it is used for reinforcing concrete, manufacturing high-tensile wire ropes, and creating durable mesh for fences and barriers. In the agricultural sector, it is used for fencing livestock and creating trellises for vine crops. The automotive industry also utilizes this wire for producing various components and fastening solutions.

Conclusion

In summary, the best cold drawn galvanized wire is an exceptional choice for those seeking a reliable, strong, and versatile wire option. Its unique combination of enhanced strength, corrosion resistance, versatility, improved appearance, and long-term cost-effectiveness makes it ideal for a wide range of applications. As industries continue to evolve, the demand for quality materials like cold drawn galvanized wire will undoubtedly grow, reflecting its importance in modern construction and manufacturing.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025