5x5 galvanized welded wire mesh factories

The Essentials of 5x5 Galvanized Welded Wire Mesh Factories

In the realm of construction and manufacturing, galvanized welded wire mesh has become an indispensable material. Particularly, the 5x5 galvanized welded wire mesh is a preferred choice for various applications due to its strength, durability, and versatility. As industries continue to expand, the demand for high-quality wire mesh from dedicated factories has surged. This article explores the significance of 5x5 galvanized welded wire mesh factories, their manufacturing processes, and the benefits they provide across different sectors.

Understanding Galvanized Welded Wire Mesh

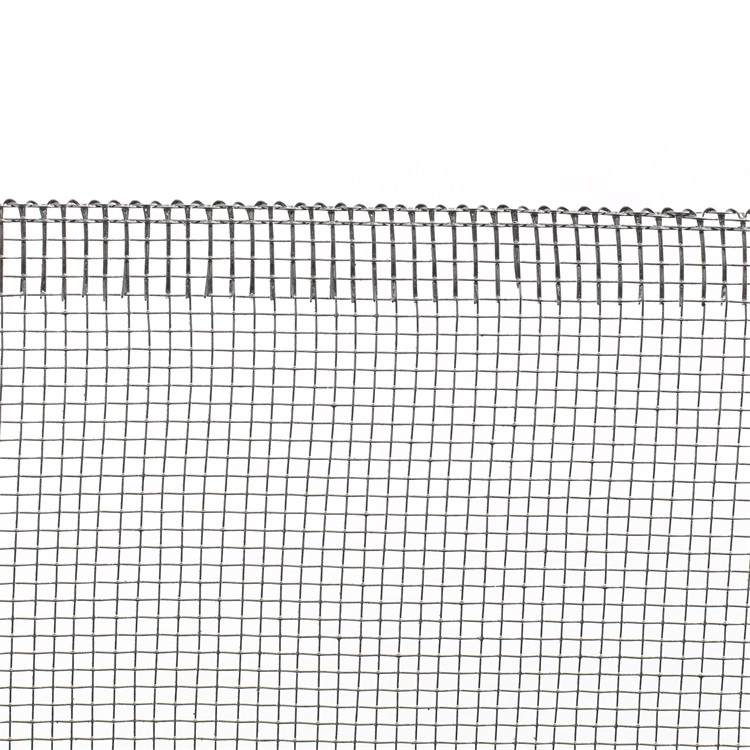

Galvanized welded wire mesh consists of wires that are welded together at intersections, creating a grid-like structure. The term galvanized refers to the process of coating the wire with a layer of zinc to prevent rust and corrosion, thereby increasing its longevity. This type of mesh is commonly used in various applications, including fencing, animal enclosures, construction reinforcement, and agricultural uses.

The 5x5 specification typically indicates the spacing of the mesh openings, which measures 5 inches by 5 inches, offering a balance between strength and visibility. Such dimensions make it ideal for applications where strength is crucial, yet visibility or airflow is desired, such as in residential fencing and animal pens.

The Manufacturing Process

The production of 5x5 galvanized welded wire mesh involves several meticulous steps to ensure high quality and durability.

1. Wire Selection The process begins with selecting high-quality steel wire, which is essential for producing strong and reliable mesh. The wire is typically drawn to the desired diameter, depending on the specific requirements of the finished product.

2. Welding Once the wire is prepared, it is automatically fed into a welding machine. Here, the wires are arranged into a grid and welded at their intersections. The precision of modern welding technology ensures that the connections are robust, creating a mesh that can withstand significant tension.

3. Galvanization After welding, the mesh undergoes galvanization. This can be achieved through hot-dip galvanization or electro-galvanization. Hot-dip galvanization results in a thicker zinc coating, offering superior protection against corrosion, making it ideal for outdoor use.

5x5 galvanized welded wire mesh factories

4. Cutting and Packaging Once the galvanization process is complete, the welded wire mesh is cut to the desired dimensions. Factories then bundle and package the mesh for distribution, ensuring that it is ready for transport to various markets.

Benefits of 5x5 Galvanized Welded Wire Mesh

The advantages of using 5x5 galvanized welded wire mesh are numerous

- Durability The galvanization process protects the wire from harsh weather conditions, making it suitable for both indoor and outdoor applications.

- Strength The welded construction enhances the structural integrity of the mesh, making it resistant to tearing and bending.

- Versatility This type of mesh is used in a wide range of applications, from construction and agricultural use to pet enclosures and security fencing.

- Cost-Effectiveness With its long lifespan and low maintenance requirements, galvanized welded wire mesh presents a cost-effective solution for many projects.

- Easy Installation The lightweight nature of the mesh allows for straightforward handling and installation, reducing labor costs and time.

Conclusion

5x5 galvanized welded wire mesh factories play a critical role in the supply chain of construction and agricultural materials. With advancements in manufacturing processes and a focus on quality, these factories produce wire mesh that meets the diverse needs of various industries. As the demand for durable and effective fencing and reinforcement solutions continues to grow, the importance of these specialized factories will only increase. With their strength, versatility, and protective qualities, 5x5 galvanized welded wire mesh remains a cornerstone material in modern construction and beyond.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025