Enhancing Strength and Durability with 20 Gauge Steel Wire Applications and Benefits

Understanding the Properties and Applications of 20% Gauge Steel Wire

Steel wire has become an indispensable material in various industries due to its strength, flexibility, and durability. Among the different specifications available, 20% gauge steel wire stands out for its unique properties and versatility. This article delves into the characteristics, manufacturing processes, and applications of 20% gauge steel wire, highlighting its significance in the modern world.

What is Gauge Steel Wire?

Before exploring the specifics of 20% gauge steel wire, it's essential to understand what gauge means in the context of wire. The term gauge refers to the diameter of the wire. The American Wire Gauge (AWG) system is commonly used in North America, where a higher gauge number indicates a thinner wire. Therefore, a 20% gauge steel wire is relatively thin, measuring around 0.81 mm (or approximately 0.032 inches) in diameter. This thinness offers unique advantages and uses across various applications.

Properties of 20% Gauge Steel Wire

The properties of 20% gauge steel wire make it particularly appealing for multiple industries. First and foremost, it exhibits excellent tensile strength, allowing it to withstand significant amounts of tension without breaking. This feature is vital in applications where the wire is subjected to pulling forces.

Additionally, its pliability enables it to be easily bent or twisted, which is advantageous for applications requiring intricate designs or configurations. The wire's resistance to corrosion and rust is another essential property, especially when used in outdoor or high-moisture environments. Many manufacturers treat their steel wire with protective coatings to enhance its longevity.

Moreover, 20% gauge steel wire is lightweight, making it easy to handle and transport. Its low density also means it can be utilized without adding considerable weight to the overall structure, which is crucial in applications like construction or automotive manufacturing.

Manufacturing Process

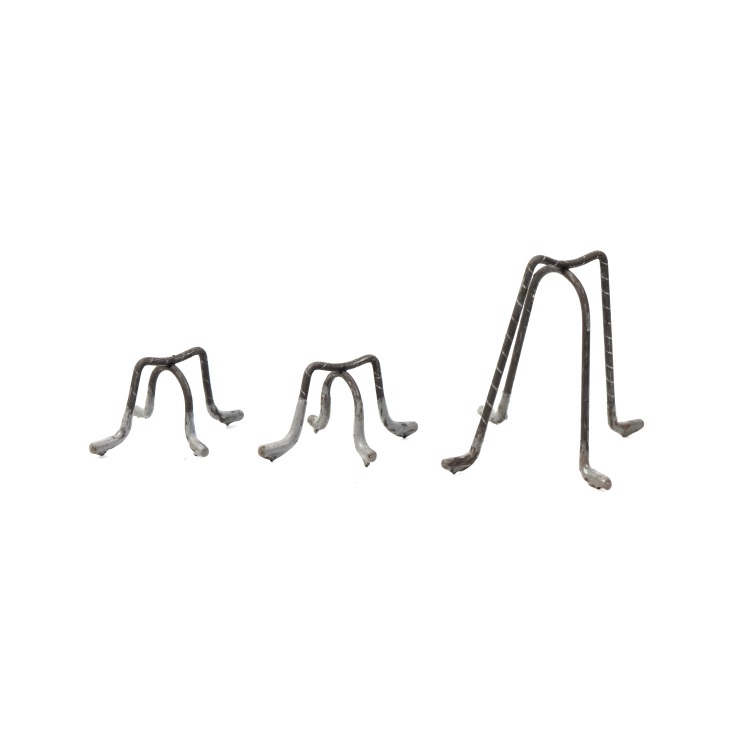

20 gauge steel wire

The manufacturing of 20% gauge steel wire involves several steps to ensure its quality and performance. Initially, raw steel is melted and then drawn through a series of dies to achieve the desired diameter. This process, known as wire drawing, helps in refining the steel's structure, enhancing its strength and durability.

Heat treatment may follow, depending on the intended use of the wire. This process involves heating the wire to a specific temperature and then cooling it rapidly or slowly, affecting its hardness and flexibility. Finally, the finished wire is often subjected to a surface treatment to protect it from corrosion, such as galvanization or plastic coating.

Applications of 20% Gauge Steel Wire

20% gauge steel wire's flexibility and strength make it suitable for a vast array of applications. In the construction industry, it is frequently used for tying rebar, anchoring, and creating wire mesh. Its lightweight nature also lends itself to use in scaffolding and temporary supports, where structural weight is a concern.

In manufacturing, this gauge of steel wire is commonly employed in creating springs, clips, and other components requiring a specific tension. Its ability to be easily manipulated makes it a favorite among craftsmen and artisans, who use it for jewelry-making, decorative items, and crafting.

Additionally, the wire’s strength and resistance to wear make it a preferred choice for electrical applications, particularly in situations requiring secure connections or supports for various wiring systems. It is also used in agriculture for fencing, trellises, and plant support structures.

Conclusion

In conclusion, 20% gauge steel wire is a remarkable material recognized for its strength, flexibility, and durability. Its diverse applications across industries underscore its significance in modern technology and craftsmanship. As manufacturing techniques continue to evolve, the uses of gauge steel wire will likely expand, demonstrating the enduring versatility and reliability of this fundamental material. Whether in construction, manufacturing, or art, 20% gauge steel wire plays a crucial role in shaping our environment and enhancing our creativity.

-

The Durability and Versatility of Steel Wire

NewsJun.26,2025

-

The Best Iron Nails for Your Construction Projects

NewsJun.26,2025

-

Strengthen Your Projects with Durable Metal Stakes

NewsJun.26,2025

-

Get the Job Done Right with Duplex Nails

NewsJun.26,2025

-

Explore the Versatility and Strength of Metal Mesh

NewsJun.26,2025

-

Enhance Your Security with Razor Wire

NewsJun.26,2025